2000 Series Aluminum Alloy Properties, Strength & Applications

What Is the 2000 Series Aluminum Alloy?

The 2000 series aluminum alloy is a high-strength aluminum-copper alloy widely used in demanding engineering applications. It is valued for its excellent mechanical strength, fatigue resistance, and performance in structural components. In aviation manufacturing, components such as wing ribs, fuselage frames, and aircraft bulkheads frequently use 2000 series aluminum because of its superior strength-to-weight ratio.

2000 Series Aluminum Properties

The 2000 series alloys have distinctive characteristics that make them suitable for heavy-duty use:

- High mechanical strength, comparable to mild steel

- Excellent fatigue resistance

- Good machinability

- Heat-treatable for enhanced performance

- Moderate corrosion resistance (often requires protective coating or cladding)

Among the most well-known alloys in this category is 2024 aluminum, which is commonly used where strong structural performance is required.

How Strong Is Aluminum 2000?

The strength of aluminum 2000 series alloys can exceed 400 MPa in tensile strength depending on the specific heat treatment and alloy composition.

Example comparison:

- General aluminum sheet: ~100–150 MPa

- 2000 series (e.g., 2024-T3): ~400–480 MPa

This makes it nearly 3–4 times stronger than basic aluminum, while still offering lower weight than steel.

If you’re exploring high-performance alternatives beyond 2000-series, check out the 9000 series aluminum alloy properties for an overview of their strength, CNC uses, and other traits.

What Is the 2000 Series Aluminum Used For?

The 2000 series aluminum is primarily used in aerospace structures, military equipment, high-performance automotive parts, industrial machinery, and precision-engineered components that require high strength and fatigue resistance. It is commonly selected for aircraft frames, rivets, structural brackets, robotic parts, and lightweight mechanical assemblies because it delivers strong load-bearing performance while remaining significantly lighter than steel.

Aerospace manufacturing (aircraft structures, fittings, wing components)

The aerospace industry relies heavily on the 2000 series aluminum because its high strength-to-weight ratio helps reduce overall aircraft mass while maintaining structural integrity. Components like wing ribs, fuselage reinforcement, and load-bearing frames often use alloys such as 2024 or 2014 for durability under continuous vibration and stress.

Defense and military applications

Military-grade equipment including armored shells, missile parts, and tactical aviation housings, benefit from the alloy’s mechanical strength and high fatigue resistance. This makes the 2000 series ideal for environments where reliability and performance under pressure are critical.

Racing and performance automotive components

In motorsport engineering, minimizing weight is essential for speed and fuel efficiency. 2000 series aluminum is used for components like gearbox housings, suspension arms, and performance engine parts, where strength matters but minimizing weight is equally important.

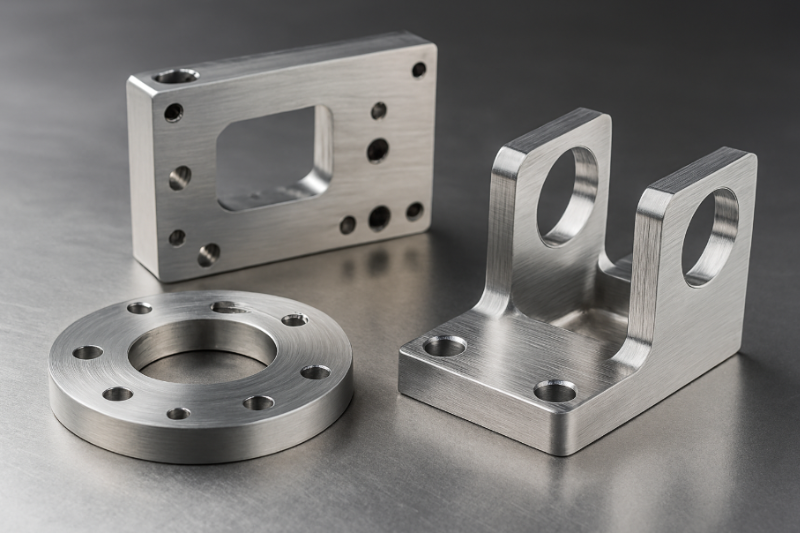

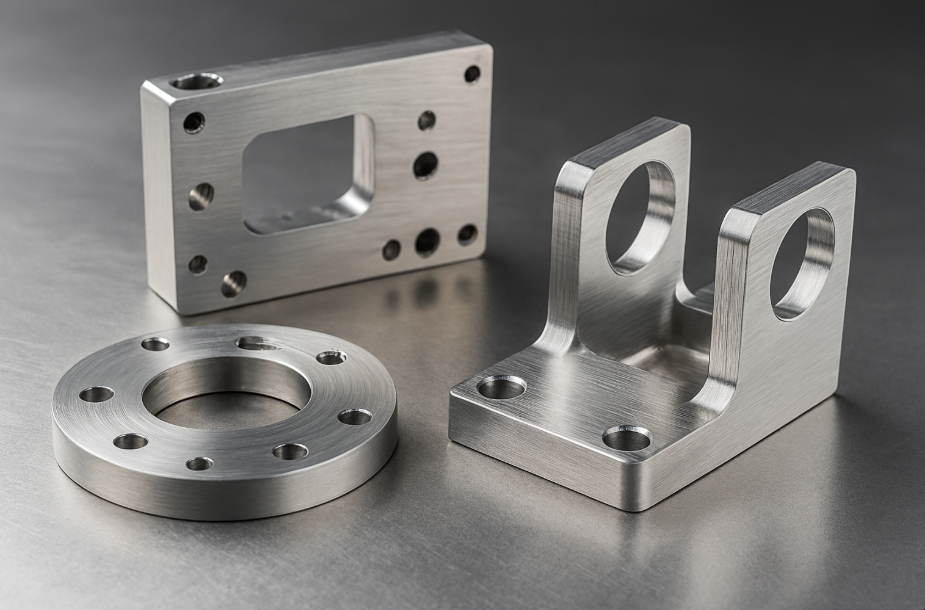

Industrial machinery and precision components

The alloy is used in machine gears, high-performance joints, structural brackets, and parts that must withstand repeated movement and mechanical stress. Its machinability also allows manufacturers to produce parts with tight tolerances and precision shapes.

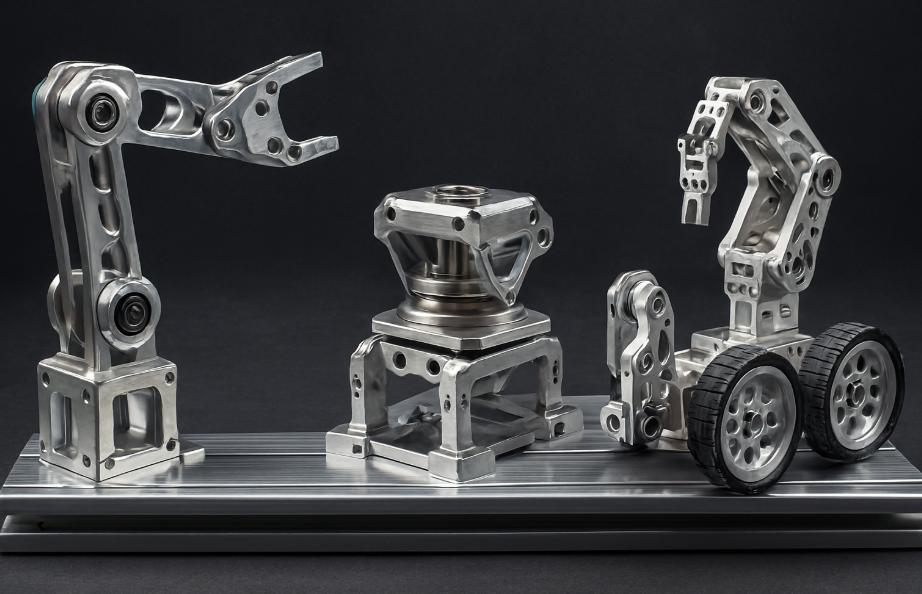

Robotics, drones, and mechanical engineering systems

Lightweight yet strong components are crucial in drones and robotic assemblies. Engineers commonly use 2024 aluminum for arm structures, motor mounts, and structural frames because it maintains stability without adding excessive mass.

High-strength rivets and fasteners

Certain 2000 series aluminum alloys are used to produce aerospace-grade rivets and fastening systems. These parts must be extremely durable because they hold together critical structural components, especially in aviation and heavy-duty engineering.

Can 2000 Series Aluminum Be Welded?

Technically, it can be welded, but it is not recommended due to the risk of cracking and reduced post-weld strength. Instead, 2000 series aluminum is commonly joined using riveting, bolting, adhesive bonding and brazing with proper treatment

For example, aircraft fuselage panels are typically riveted rather than welded to preserve material integrity.

While 2000-series aluminum can technically be welded, you may face post-weld strength loss and increased risk of cracking. Learn more about the challenges and best practices at our can aluminium be welded guide.

2000 Series Aluminum vs Other Alloy Families

1000 Series Aluminum (Commercially Pure Aluminum)

The 1000 series aluminum is at least 99% pure aluminum and is widely used where excellent corrosion resistance and high electrical or thermal conductivity are required. Because it is the softest and most ductile aluminum family, it is commonly used for electrical busbars, chemical equipment, heat exchangers, and food processing applications. This series is easy to form and polish, but not suitable for high-strength structural loads.

2000 Series Aluminum (Aluminum-Copper Alloys)

The 2000 series aluminum alloy contains copper as its principal alloying element, giving it exceptional mechanical strength and fatigue resistance. This makes it ideal for aerospace structures, high-performance automotive parts, defense equipment, and other load-bearing applications. While it has lower natural corrosion resistance compared to other alloys, it is often coated or clad for protection and preferred when strength-to-weight performance is critical.

3000 Series Aluminum (Aluminum-Manganese Alloys)

The 3000 series aluminum offers improved strength over pure aluminum while maintaining good formability and corrosion resistance. It is commonly used in roofing sheets, storage tanks, cooking utensils, and general fabrication. This alloy family strikes a balance between durability and cost, making it popular for non-structural industrial and consumer applications where moderate performance is sufficient.

5000 Series Aluminum (Aluminum-Magnesium Alloys)

The 5000 series aluminum provides excellent corrosion resistance, particularly in marine environments, due to the addition of magnesium. This makes it a preferred choice for shipbuilding, offshore structures, tankers, and pressure vessels. It is weldable and maintains strength after forming, which is why it’s widely used in ocean-facing infrastructure and transportation.

6000 Series Aluminum (Aluminum-Magnesium-Silicon Alloys)

The 6000 series aluminum is highly versatile and known for its excellent extrudability, moderate strength, and strong corrosion resistance. It is commonly used in construction frameworks, architectural extrusions, automotive body parts, window frames, and structural profiles. Because it can be heat-treated and anodized, it is one of the most widely used aluminum families across engineering and construction industries.

In Singapore’s precision engineering, aerospace supply chain, and manufacturing sectors, this alloy is preferred because it supports weight reduction without compromising strength. It enables high-performance assembly in limited spaces. Also, it delivers consistent performance under stress and load cycles.

Companies that supply aviation parts, UAV components, and high-precision machined structures frequently choose the 2024 and 2014 variants for durability and performance.

We supply 2024, 2014 and other variants in sheet, plate, bar, check on our aluminium flat bar sizes and uses for standard dimensions.

2000 Series Aluminum Alloy Supplier

As a specialised 2000 series aluminum alloy supplier in Singapore, The Monster Builder provides high-grade aerospace and engineering aluminum with verified certifications and proven mechanical performance. We supply 2024, 2014, and related 2000 series variants in sheet, plate, bar, and custom-cut formats and we go further by offering professional aluminium fabrication services, including CNC machining, precision cutting, bending, drilling, and component finishing.

Our team works closely with engineers, procurement departments, and manufacturers to recommend the right alloy specifications and temper conditions for real-world applications such as aircraft components, industrial machinery parts, UAV frames, and high-load structural assemblies. With traceable sourcing, fabrication expertise, and fast delivery, we are a trusted local partner for businesses that require both material supply and end-to-end aluminum fabrication solutions. Contact us today!