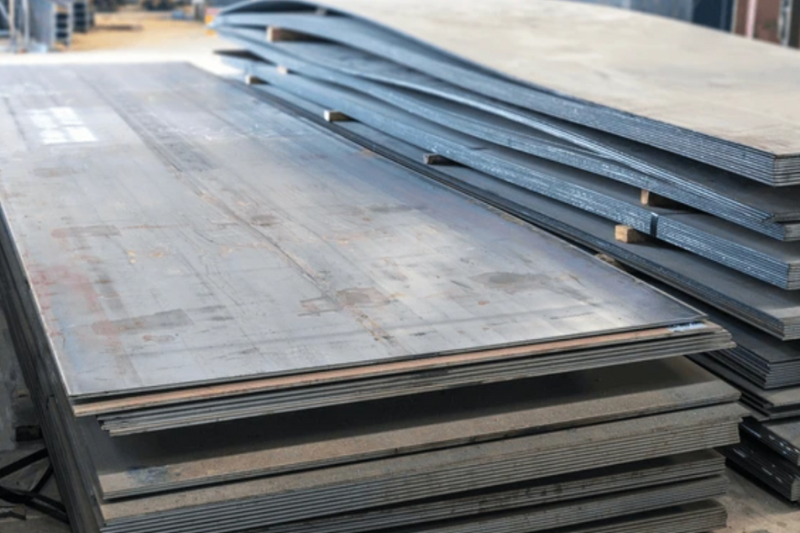

3 Main Types of Carbon Steel

Carbon steel is one of the most important materials used across Singapore’s construction and industrial sectors. Known for its strength, versatility, and affordability, carbon steel continues to play a vital role in everything from high-rise buildings to precision tools. By understanding the different types of carbon steel and their properties, businesses and engineers can make informed choices for their projects.

What Is Carbon Steel?

Carbon steel is a type of steel where carbon is the main alloying element, usually ranging from 0.05% to 1.5%. It is valued for its strength, durability, and affordability. Depending on its carbon content, carbon steel is classified as low, medium, or high, each offering different properties and uses.

This flexibility makes carbon steel suitable for a wide range of applications in Singapore’s fast-growing industries such as construction, oil and gas, manufacturing, and automotive.

3 Types of Carbon Steel

Carbon steel is divided into three main categories. Each type offers different properties that determine its performance and common uses.

Low Carbon Steel

Low carbon steel, also known as mild steel, contains less than 0.25% carbon. It is soft, ductile, and highly weldable, making it easy to machine and form. Because of its affordability and versatility, low carbon steel is widely used in structural beams, pipelines, automotive panels, and general engineering applications.

It is the preferred choice for HDB structural frameworks, pipelines in oil and gas facilities, and warehouse construction. It is also commonly fabricated into mild steel C channels, which are widely used in construction and engineering projects. Local fabrication workshops often rely on low carbon steel for customised parts since it adapts well to machining and shaping.

Medium Carbon Steel

Medium carbon steel contains about 0.25% to 0.6% carbon. It offers a balance of strength and ductility, making it tougher than low carbon steel but still workable. After heat treatment, it gains better wear resistance, which is why medium carbon steel is commonly used in gears, axles, railway tracks, and machinery parts.

It is a trusted material in precision engineering and machinery manufacturing across Singapore. Fabricators use medium carbon steel for marine equipment, gear parts, and axles where wear resistance is critical. Businesses value it for its ability to extend the service life of machinery without excessive maintenance.

High Carbon Steel

High carbon steel contains between 0.6% and 1.5% carbon, giving it exceptional hardness and wear resistance. While it is less ductile and harder to weld, its strength makes it ideal for tools and applications that need durability. Common uses include cutting blades, springs, wires, and industrial equipment.

High carbon steel is harder and stronger than other types, though this also makes it more difficult to weld and machine. For local manufacturers, its durability translates to lower replacement costs and higher reliability in heavy-duty operations.

Carbon Steel Properties

Carbon steel is valued for a set of key properties that make it one of the most widely used materials in Singapore’s construction, engineering, and manufacturing sectors. Each property influences how the steel is selected for specific projects.

- Strength and durability – Carbon steel provides high tensile strength, allowing it to withstand heavy loads. This is why it is used in Singapore’s high-rise buildings, MRT tunnels, and bridge structures.

- Toughness and wear resistance – Medium and high carbon steels offer better resistance against wear and abrasion, making them suitable for machinery and marine equipment in Jurong and Tuas.

- Ductility and formability – Low carbon steel can be easily bent, rolled, or shaped, which makes it ideal for pipe fabrication, beams, and customised metalwork.

- Weldability – Mild steel, in particular, is known for excellent weldability, allowing fabricators in Singapore to create strong joints for construction and oil & gas pipelines.

- Heat treatment adaptability – Medium and high carbon steels respond well to hardening and tempering, giving engineers flexibility in designing parts that need specific mechanical properties.

- Cost efficiency – Compared to alloy steels or stainless steel, carbon steel is affordable, which helps businesses in Singapore manage project costs without compromising performance.

- Corrosion behaviour – While carbon steel is strong, it is prone to rust without protective coatings. That’s why many Singapore projects use galvanisation, painting, or special coatings to extend lifespan in humid and coastal environments.

One of the advantages of carbon steel, especially mild steel, is its machinability. Many Singapore workshops rely on the milling machine to shape and fabricate carbon steel into customised components.

Carbon Steel Uses in Singapore

Carbon steel is one of the most versatile materials available, and in Singapore it plays a critical role across multiple industries. Its combination of strength, affordability, and adaptability makes it the backbone of many projects.

- Construction and Infrastructure – Carbon steel is widely used in HDB housing, MRT expansion projects, bridges, and industrial warehouses. It also forms the base material for lip channels in Singapore which provide strong support in roofing and structural applications. Its load-bearing capacity and reliability make it a trusted choice for beams, columns, and reinforcement bars.

- Oil and Gas Sector – Singapore’s role as an energy hub means carbon steel is essential for pipelines, pressure vessels, and fittings in refineries and petrochemical plants. Low and medium carbon steels are preferred for their weldability and durability.

- Marine and Shipbuilding – With Singapore’s strong maritime industry, carbon steel is used for ship parts, offshore platforms, and port infrastructure. Heat-treated medium carbon steel is especially valued for its resistance to wear in marine conditions.

- Manufacturing and Engineering – Medium and high carbon steels are used for machinery components, gear systems, axles, and industrial equipment in Jurong and Tuas, where heavy manufacturing and engineering activities are concentrated.

- Everyday Applications – Beyond large industries, carbon steel is also found in kitchen knives, hand tools, and springs, reflecting its versatility in daily life.

Conclusion

Carbon steel remains one of the most reliable and versatile materials in Singapore, supporting industries from construction and marine to manufacturing and everyday tools. Each type like low, medium, and high carbon steel offers unique properties that make it suitable for specific applications, whether it’s structural frameworks, machinery parts, or precision tools.

At The Monster Builder, we work closely with businesses and contractors to deliver quality steel solutions that meet Singapore’s demanding standards. With expertise in fabrication and a deep understanding of carbon steel properties and uses, our team ensures every project benefits from the right material and the right approach. Our team offers stainless steel CNC machining to ensure accuracy and quality in every component. Interested? Contact us today!