3D Printing Materials Guide: Types, Applications

3D printing has become a key manufacturing solution for industries in Singapore, from rapid prototyping to end-use production parts. Choosing the right material is the most important step, since it determines strength, durability, cost, and appearance of your final part.

What Materials Does a 3D Printer Use?

A 3D printer typically uses plastics, resins, powders, and metals depending on the printing technology:

- Thermoplastics (filaments) – PLA, ABS, PETG, Nylon, TPU for FDM 3D printing.

- Photopolymer resins – standard, tough, flexible, castable, clear for SLA/DLP printing.

- Powders – nylon (PA12), TPU, polypropylene for SLS printing.

- Metal powders – stainless steel, aluminum, titanium, Inconel for metal 3D printing.

These materials differ in strength, flexibility, heat resistance, and surface finish, making the right choice critical for your project.

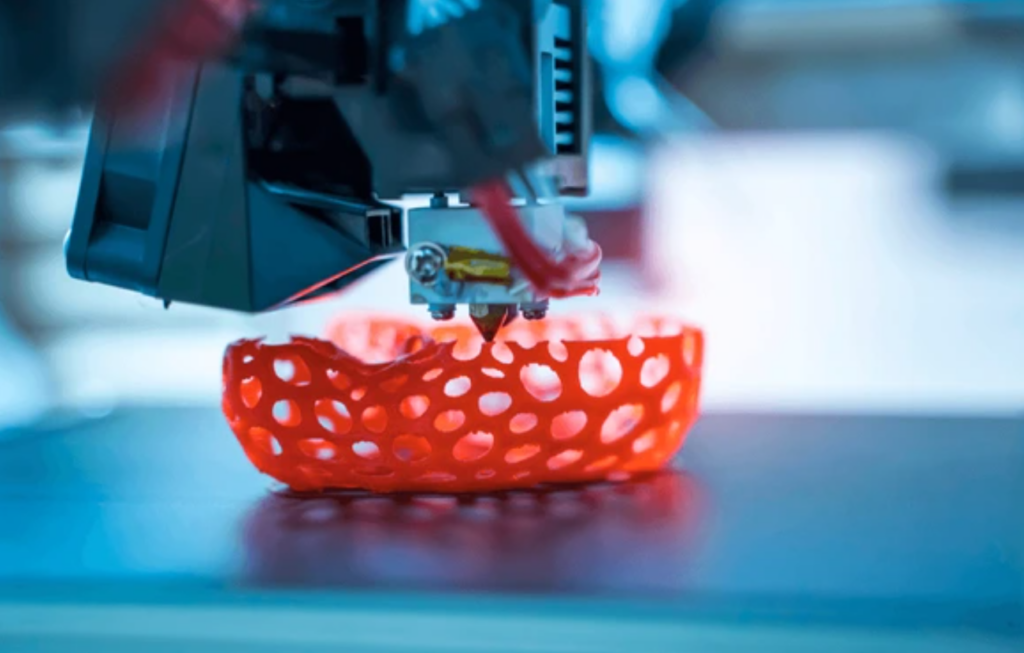

Plastic 3D Printing Materials

Plastic is the most widely used material in 3D printing because it is affordable, versatile, and available across multiple processes (FDM, SLA, SLS). Below is a breakdown of the most popular plastics, their properties, and when to use them.

Common Plastic 3D Printing Materials

- PLA (Polylactic Acid): A biodegradable, affordable filament that is easy to print and ideal for visual prototypes and low-stress models. It offers a smooth surface finish but has low heat resistance and is brittle compared to engineering plastics.

- ABS (Acrylonitrile Butadiene Styrene): Stronger and more heat-resistant than PLA, making it suitable for functional parts, enclosures, and automotive applications. It requires a heated bed and enclosure to prevent warping and produces fumes during printing.

- PETG (Polyethylene Terephthalate Glycol): A balance between PLA and ABS. It is durable, chemical-resistant, and easier to print than ABS, with fewer warping issues. Commonly used for industrial housings, fixtures, and outdoor parts.

- Nylon (Polyamide PA6/PA12): A tough, wear-resistant material with excellent flexibility and fatigue resistance. Best for mechanical parts like gears, hinges, and functional prototypes. It requires careful handling since it absorbs moisture and warps without controlled conditions.

SLA 3D Printing Materials (Resin)

SLA, or stereolithography, is valued for producing high-resolution, isotropic parts with exceptionally smooth surfaces. Instead of filaments, it uses liquid photopolymer resins that are cured by a laser or projector. This makes SLA ideal for cosmetic parts, precision prototypes, and applications where surface detail is critical.

The most common resin categories include standard resins for display prototypes, tough or engineering resins for mechanical parts that need strength, and flexible resins for rubber-like components. Specialized options such as castable resins are widely used in jewelry and dentistry, while clear resins allow the production of transparent components like light guides or lenses. More advanced formulations offer heat resistance, biocompatibility, or electrostatic dissipation (ESD), enabling use in medical or electronics fields.

SLA’s biggest strength lies in its accuracy and finish, parts often come out smooth enough to use without machining. However, the trade-off is that SLA parts are usually more brittle than FDM thermoplastics and may degrade if exposed to UV light outdoors.

In practice, SLA is the preferred option for dental and medical models, jewelry masters, transparent demo parts, and prototypes where fine surface detail matters more than long-term durability.

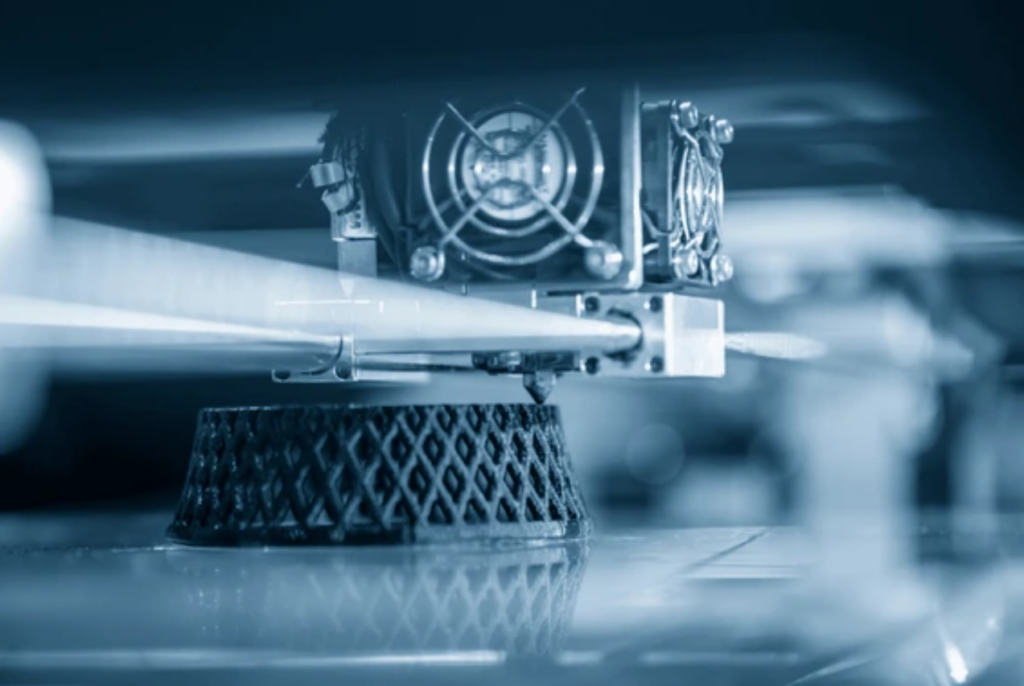

SLS 3D Printing Materials (Powders)

Selective Laser Sintering (SLS) is best known for producing strong, functional parts directly from powder. Unlike FDM or SLA, SLS does not require support structures the unused powder itself supports the print. This makes it excellent for complex geometries, internal channels, and assemblies that would be impossible with other technologies.

The most common SLS material is nylon (PA12), a lightweight yet tough polymer with good chemical resistance. Variants like glass-filled or carbon-filled nylon add stiffness for demanding engineering applications. TPU powders are also available, enabling flexible parts that combine elasticity with SLS’s durability.

SLS produces durable, isotropic parts that are well suited for snap-fit assemblies, industrial jigs, housings, and small-batch production runs. The main limitation is surface quality. SLS parts have a grainy texture that usually requires post-processing. In addition, both equipment and material costs are significantly higher than FDM.

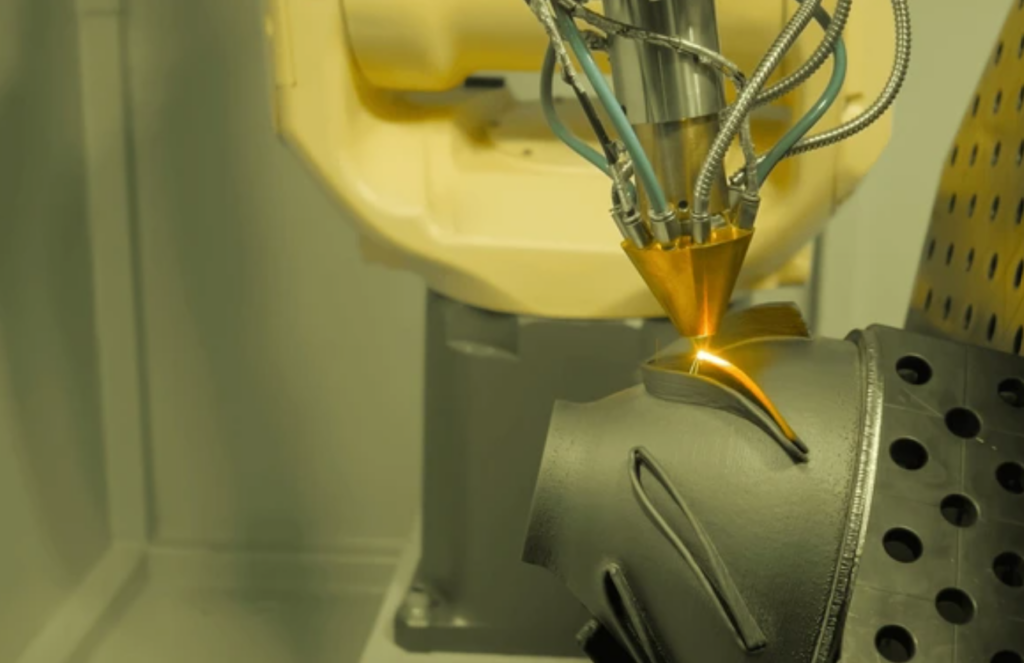

Metal 3D Printing Materials

Metal 3D printing takes additive manufacturing into the highest-performance category, producing end-use functional metal components that rival or even outperform traditionally machined parts. It uses fine metal powders such as stainless steel, aluminum, titanium, and Inconel that are fused by laser or electron beam.

The advantages are substantial: parts have a high strength-to-weight ratio, excellent durability, and can be tailored to highly complex geometries. This makes metal 3D printing invaluable in aerospace, automotive, and medical industries, where lightweight strength and precision are critical.

The trade-offs are cost and complexity. Both equipment and materials are expensive, and printed parts typically require post-processing, such as CNC machining for precision tolerances or heat treatment to relieve stresses.

Despite these challenges, metal 3D printing is the go-to solution for aerospace turbine components, medical implants, and custom high-strength tooling, applications where no other process can deliver the same combination of strength, precision, and design flexibility.

How to Select the Right 3D Printing Material

When selecting a 3D printing material, follow these five steps to match properties with your project needs:

1. Check Mechanical Strength

Look at tensile strength (resistance to pulling forces) and flexural modulus (stiffness under bending). Example: Choose Nylon (PA12) or ABS if the part must withstand mechanical stress, such as brackets, gears, or housings.

2. Evaluate Thermal Resistance

Consider the heat deflection temperature (HDT) or glass transition temperature (Tg) of the material. Example: ABS, PC, or high-temp SLA resins are better than PLA if the part will be exposed to heat (e.g., electronics housings in Singapore’s humid climate).

3. Define Surface Finish Requirements

Decide if your part needs cosmetic smoothness or functional durability. Example: For visual models, SLA resins produce smooth, polished parts; for rugged use, FDM with PETG or Nylon may be more suitable.

4. Measure Flexibility Needs

Look at elongation at break and Shore hardness when flexibility or elasticity matters. Example: Use TPU filament or flexible SLA resin for gaskets, footwear, or medical wearables.

5. Balance Cost vs Production Scale

Consider whether the project is a prototype, low-volume run, or mass production. Example: Start with PLA or PETG for fast, affordable prototypes, and move to plastic injection molding if you need thousands of parts.

Conclusion

Choosing the right 3D printing material is the key to getting parts that match your project’s needs whether that means smooth cosmetic prototypes, durable functional components, or high-strength industrial parts.

At The Monster Builder, we provide professional 3D printing services in Singapore, including FDM 3D printing, SLA 3D printing, SLS 3D printing supported by CNC machining, metal fabrication and plastic injection molding for complete production solutions.