9000 Series Aluminum Alloy Properties & CNC Uses

What Is 9000 Series Aluminum Alloy?

The 9000 series aluminum alloy is an advanced aluminum formulation used primarily in high-strength and high-precision engineering applications. Unlike conventional 1000, 6000, or 7000 aluminum grades, the 9000 series integrates highly specialized alloying elements that improve structural stability, machinability, and thermal resistance.

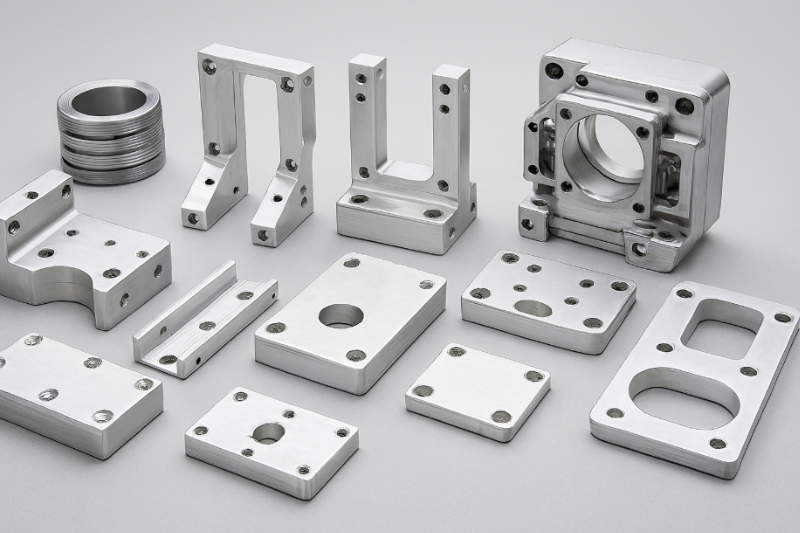

9000 series aluminum is designed for strength, precision, and durability in demanding environments. For the Singapore market, this alloy is increasingly selected for electronics manufacturing, CNC precision parts, robotics components, aerospace-related prototypes, and industrial automation systems.

9000 Series Aluminum Alloy Properties

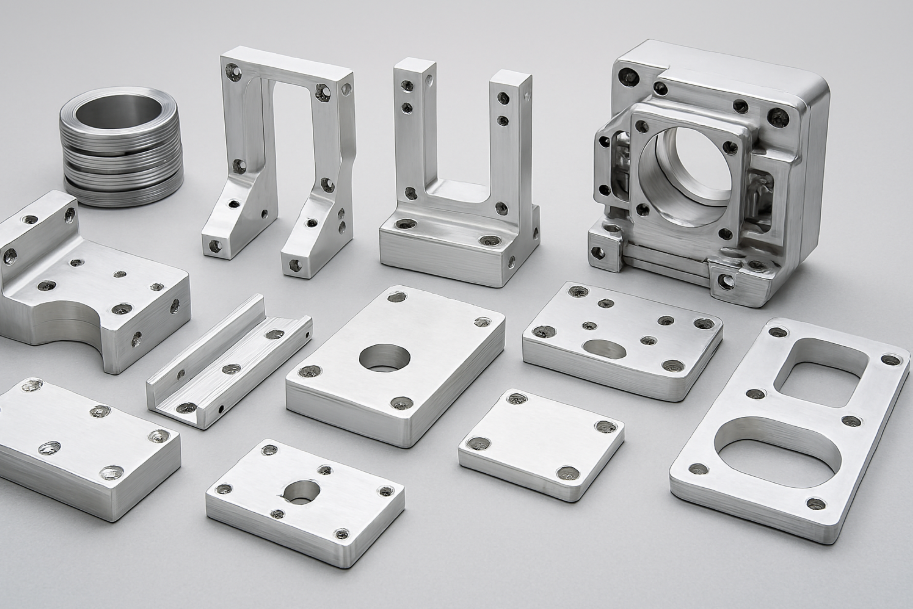

Here are the key material characteristics engineers and procurement teams in Singapore consider:

- High strength-to-weight ratio — excellent for load-bearing parts without increasing mass.

- Superior machinability — performs well on CNC milling, turning, and drilling.

- Good corrosion resistance — suitable for humid Southeast Asian environments.

- Dimensional stability — maintains tolerances during cutting and machining.

- Optional heat-treatable variants — depending on final application requirements.

Is 9000 Series Aluminum Heat Treatable?

Yes. Some variants of the 9000 series aluminum alloy are heat treatable, meaning they can be strengthened through controlled heating and cooling processes depending on the specific composition and application.

What Is 9000 Series Aluminum Used For?

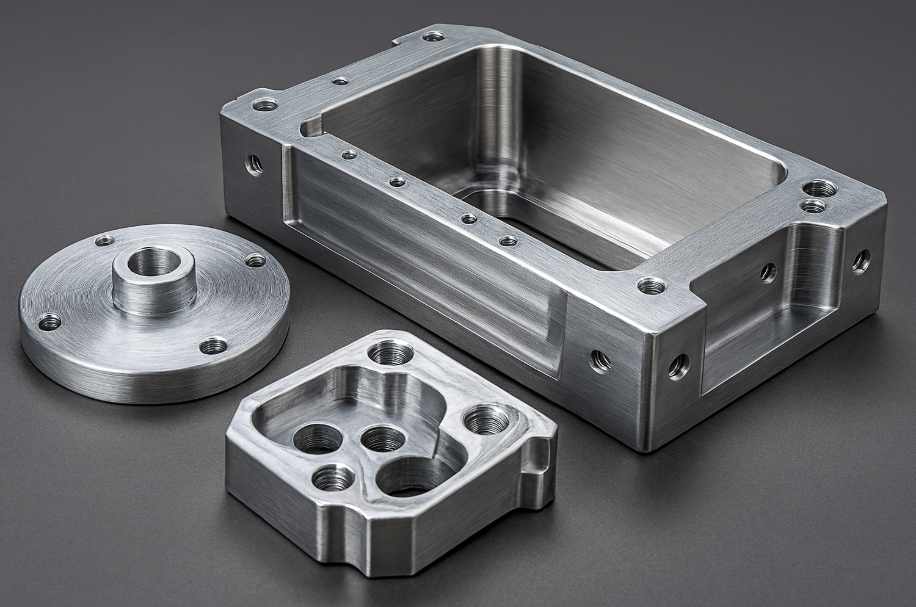

The 9000 series aluminum alloy is used for high-precision engineering applications, including CNC-machined components, robotics and automation parts, aerospace prototyping, heat-resistant electronics housings, and durable mechanical fixtures. Its combination of strength, excellent machinability, and dimensional stability makes it ideal for industries that require tight tolerances, lightweight performance, and long-term reliability.

A robotics manufacturer in Singapore required lightweight actuator brackets with tight tolerances and minimal deformation. By choosing the 9000 series aluminum alloy, they achieved a 28% reduction in component weight, 17% improvement in dimensional accuracy and a longer operational fatigue life.

This material choice supported improved robotic movement efficiency and lower maintenance frequency.

For basic flat-stock components, we source from our standard aluminium flat bar sizes & uses inventory to ensure consistent thickness and quality.

For façade or ventilation projects, we supply aluminium louvers applications & supply in Singapore, designed to resist corrosion while providing airflow.

Why Choose The Monster Builder for 9000 Series Aluminum CNC Services?

Choosing The Monster Builder means working with a team that prioritises precision engineering, material expertise, and results-driven manufacturing. We don’t just machine parts, we guide you on material selection, recommend structural optimisations, and ensure every component meets performance specifications.

Over the years, we’ve successfully supported Singapore-based clients in robotics, electronics manufacturing, and industrial automation by delivering CNC parts with micron-level tolerances and excellent structural stability.

For example, we helped a local robotics integrator reduce actuator component weight while improving durability using the 9000 series aluminum, resulting in smoother robotic movement and lower maintenance downtime. We provide full quality documentation, design-for-manufacturing insights, and reliable lead times, ensuring your project is delivered accurately, efficiently, and engineered to perform.

We also offer aluminium hollow section use-cases & cutting guide for square and rectangular tubing, ideal for lightweight but strong frameworks.

6000 vs 7000 vs 9000 Aluminum Alloy

The 6000 series aluminum is affordable and highly machinable for general fabrication, the 7000 series is extremely strong for high-stress applications like aerospace, and the 9000 series offers the best precision and dimensional stability for advanced machining, robotics, and specialized engineering projects.

6000 Series Aluminum:

The 6000 series aluminum is widely used because it offers a balanced combination of strength, machinability, and cost efficiency. It’s ideal for general fabrication, structural components, frames, and consumer-grade applications where moderate strength and easy forming are required. Many Singapore manufacturers choose 6000 series aluminum for reliable, versatile production without significantly increasing material costs.

7000 Series Aluminum:

The 7000 series aluminum is known for extremely high strength and toughness, making it suitable for aerospace, motorsports, and engineering components that operate under heavy stress. While more expensive and harder to machine than the 6000 series, its superior tensile strength and fatigue resistance make it a preferred choice for high-performance mechanical parts, load-bearing assemblies, and demanding structural environments.

9000 Series Aluminum:

The 9000 series aluminum excels in precision engineering where dimensional accuracy, lightweight performance, and machining stability are critical. This alloy delivers excellent structural reliability and consistent tolerances, making it ideal for robotics, high-precision CNC machining, defence and automation components, and advanced industrial applications. For companies requiring near-zero deformation and tight manufacturing tolerances, 9000 series aluminum is the superior choice.

If your project requires maximum precision, reliability, and stability, the 9000 series is the superior choice.

Request a Material Recommendation

Many engineers and procurement teams struggle with choosing the correct alloy because selecting the wrong material can lead to part failure, unexpected deformation, higher machining costs, or unnecessary over-specification.

At The Monster Builder, we remove that uncertainty by analyzing your functional load requirements, machining tolerances, operating temperature, environmental exposure, and cost–performance balance. Instead of guessing or relying on generic material charts, you get a tailored engineering recommendation backed by real manufacturing experience.

Simply send us your technical drawings or specifications, and our team will determine whether the 9000 series aluminum or a better-suited alternative will deliver the best performance, reliability, and value for your project.

Explore our full suite of aluminium fabrication services Singapore, from raw-material selection to finishing and delivery