Chequered Plate vs Plain Steel Plate

What Is a Chequered Plate?

A chequered plate is a type of metal sheet featuring raised patterns such as diamonds or lines. It also known as a tread plate, diamond plate, or floor plate. These embossed surfaces improve slip resistance, making them ideal for high-traffic and safety-critical areas.

Key features:

- Made from mild steel (MS), aluminium, or stainless steel

- Thickness range: 2 mm to 12 mm

- Durable and corrosion-resistant depending on material grade

Commonly used in steel fabrication, sheet metal fabrication and metal fabrication projects that require strength, safety and anti-slip performance.

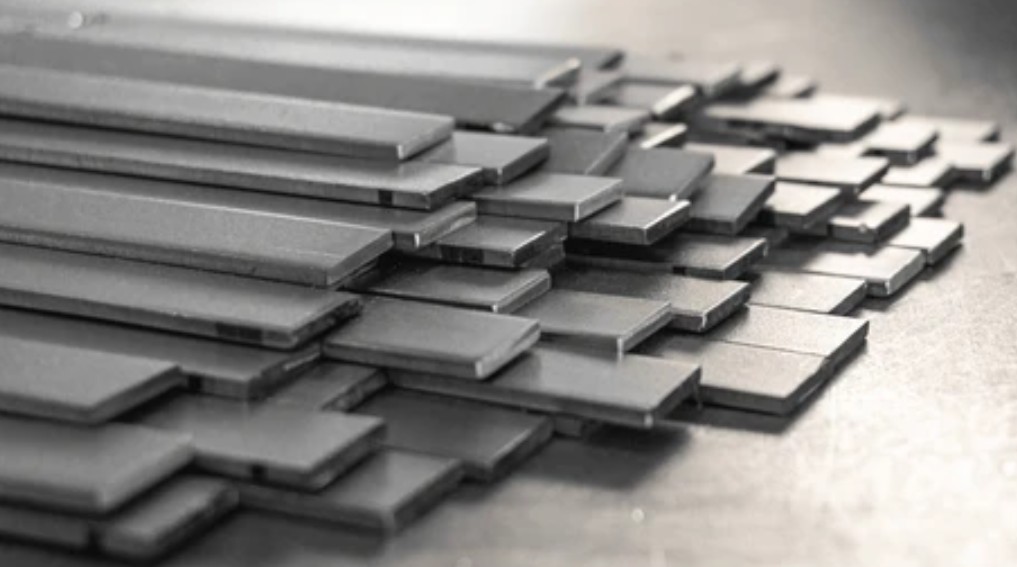

What Is a Standard Flat Steel Plate?

A flat steel plate is a smooth, untextured sheet of steel with no raised patterns. It is one of the most widely used raw materials in construction and fabrication because of its versatility and cost efficiency.

Standard Flat Steel Plate Applications includes:

- Building and infrastructure projects

- Shipbuilding and tanks

- Machinery and equipment parts

- Welding and fabrication projects

At The Monster Builder, we use flat plates in CNC machining, aluminium sheet fabrication and plastic injection molding to create precision components for custom projects.

Key Differences Between Chequered Plate and Standard Flat Steel Plate

Chequered plates and flat steel plates differ mainly in their surface design, functionality, and applications. While chequered plates feature raised patterns that improve slip resistance and stiffness, flat steel plates offer a smooth surface that makes them versatile for structural and fabrication purposes. The table below highlights the main differences at a glance:

| Feature | Chequered Plate | Standard Flat Plate |

|---|---|---|

| Surface | Raised diamond/linear patterns | Smooth surface |

| Slip Resistance | Excellent for safety under wet/oily use | Minimal unless coated |

| Strength | Stiffer due to embossing | Uniform load distribution |

| Weight | Slightly heavier (patterns add ~10%) | Lighter at same thickness |

| Cost | Higher due to extra processing | More economical |

| Applications | Ramps, walkways, flooring, stair treads | Construction, tanks, structural parts |

How to Calculate Weight of MS Chequered Plate

Weight calculation uses the formula:

Weight (kg) = Length (m) × Width (m) × Thickness (m) × Density (7,850 kg/m³)

For chequered plates, add ~10% extra to account for raised patterns.

Example: A 2 m × 1 m × 6 mm MS chequered plate ≈ 103 kg.

Weight matters in sheet metal fabrication and steel fabrication projects as it impacts load capacity, handling and costs.

Where to Use Chequered Plate?

Chequered plates are mainly used for flooring, ramps, stair treads, and industrial walkways because their raised patterns provide slip resistance and durability.

Common applications include:

- Industrial floors, factory walkways, and catwalks

- Public ramps, staircases, and ladders

- Vehicle decks, truck beds, and trailer flooring

- Ship decks, offshore platforms, and heavy-duty ramps

This positions chequered plate as the best choice where safety and anti-slip performance are essential.

Where to Use Standard Flat Steel Plate?

Flat steel plates are widely used in construction, fabrication, and machinery parts where a smooth surface and uniform strength are required.

Typical uses include:

- Building structures, bridges, and reinforcements

- Shipbuilding, storage tanks, and heavy machinery

- Welded assemblies and fabrication works

- General engineering and precision machining

This makes flat steel plate the preferred option for structural and fabrication projects.

What Is the Price of Chequered Plate in Singapore?

Pricing varies by material grade, thickness, and supplier:

- Stainless Steel 304 Chequered Plate: ~USD 1,300–1,800 per ton

- AISI 304 Checker Plate: ~USD 750–1,800 per ton

- 316L Stainless Steel Chequered Plate: ~USD 2,300–2,900 per ton

- Mild Steel Chequered Plate: More affordable, with lower tonnage rates

Note: The above prices are sourced from industry publications and competitor references. Actual costs in Singapore may differ depending on local suppliers, import duties, and market fluctuations. For an accurate quotation, please contact us directly.

Is Chequered Plate Stronger Than Flat Plate?

Yes, chequered plates are generally stiffer and more resistant to bending than flat steel plates of the same thickness because of their raised patterns. However, flat plates provide more uniform strength and are often preferred for heavy structural and load-bearing applications.

Conclusion

Both chequered plates and flat steel plates are vital in the fabrication industry. Chequered plates shine in anti-slip and safety roles, while flat plates excel in structural and fabrication uses.

To see how these materials fit into the wider production process, check out our guide on how metal fabrication works. It explains the step-by-step methods used in modern fabrication, from raw material processing to custom part creation.

At The Monster Builder, we provide full solutions in metal fabrication, sla 3d printing and more to support your projects in Singapore.