What Materials Can Be Used in 3D Printing?

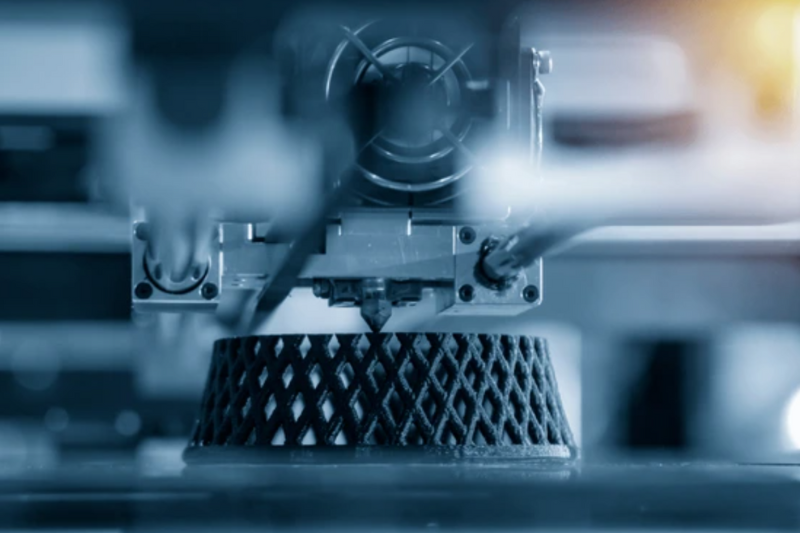

3D printing is no longer limited to hobbyists. Today, it plays a critical role in industries like manufacturing, engineering, healthcare, and product design. But a common question many clients ask is ” What materials can be used in 3D printing?”

The answer depends on the type of 3D printer, the purpose of the part, and the properties required. From plastics to metals, 3D printing materials offer a wide range of possibilities.

Types of 3D Printing Materials

The materials used in 3D printing are diverse, each offering unique properties to suit different applications. From affordable plastics for quick prototyping to metal alloys for industrial use, selecting the right material ensures your part performs as expected. Below are the most widely used materials in 3D printing and why they are effective.

Plastics

Plastics are the most common 3D printing material because they are lightweight, versatile, and cost-effective. They can be melted, extruded, and cooled quickly, which makes them perfect for additive manufacturing.

Types of Plastics for 3D Printing:

- PLA (Polylactic Acid): Biodegradable, easy to print, ideal for prototypes and hobbyist models.

- ABS (Acrylonitrile Butadiene Styrene): Strong, impact-resistant, commonly used for functional parts.

- PETG (Polyethylene Terephthalate Glycol): Combines strength with flexibility, resistant to moisture.

- Nylon (Polyamide): Durable and flexible, used in gears, fittings, and mechanical prototypes.

When to Use:

- Product design and prototyping

- Educational models

- Functional but low-stress mechanical parts

If you need prototype fabrication, our FDM 3D printing services are the most cost-effective option for you.

Resins

Resins are liquid polymers that solidify under light (UV laser or LCD). This makes them perfect for high-detail printing, producing smooth finishes that plastics alone can’t achieve.

Types of Resins:

- Standard Resin: For cosmetic models and display pieces.

- Clear Resin: Allows transparent parts (e.g., lenses, demo optics).

- Tough Resin: More durable for mechanical testing.

- Castable Resin: Ideal for jewellery and dental molds due to clean burnout.

When to Use:

- Prototypes with fine detail

- Dental and medical models

- Jewellery casting masters

- Transparent functional samples

For high detail and precision applications, you can check out our SLA 3D printing services.

Metals

Metals are suitable for functional, end-use parts that require strength, heat resistance, and durability. Powdered metals are fused layer by layer using high-energy lasers or electron beams.

Common 3D Printing Metals:

- Stainless Steel: Corrosion-resistant, ideal for tools and fixtures.

- Aluminium: Lightweight, strong, widely used in aerospace and automotive.

- Titanium: Exceptional strength-to-weight ratio, used in aerospace and medical implants.

- Cobalt-Chrome: Biocompatible, suitable for dental and surgical parts.

When to Use:

- High-stress mechanical components

- Aerospace or automotive lightweight parts

- Medical implants or surgical tools

For projects requiring industrial-grade metals, we also provide CNC machining and aluminium sheet fabrication.

Composites

Composites combine polymers with reinforcing materials like carbon fibre or glass fibre. This gives them superior strength and stiffness without adding much weight.

Popular Composite Materials:

- Carbon Fibre-Reinforced Nylon: Extremely strong, lightweight.

- Glass Fibre-Reinforced Filaments: High rigidity for structural parts.

- Wood or Ceramic Composites: Used for decorative or artistic parts.

When to Use:

- Lightweight but durable functional parts

- Automotive and aerospace applications

- Specialised artistic or architectural projects

Our hybrid solutions include sheet metal fabrication and plastic injection molding to complement 3d printing.

Benefits of 3D Printing Materials

Choosing the right material is not just about “what can be printed”, it’s about ensuring the final part performs exactly as intended. Different 3D printing materials bring unique strengths, making the technology useful across industries from manufacturing to healthcare. Below are the main benefits and why they matter to your project.

1. Rapid Prototyping and Faster Development

3D printing materials like PLA and resin allow quick design iterations without expensive tooling. This helps businesses reduce errors early and bring products to market faster.

2. Lightweight but Strong Parts

Materials such as aluminium and carbon fibre composites provide excellent strength-to-weight ratios. This is especially useful in industries like aerospace and automotive, where efficiency matters.

3. High Customisation and Complex Designs

Resins and plastics can produce intricate shapes that traditional methods can’t achieve. This makes them ideal for customised medical devices, prototypes, or detailed models.

4. Cost-Effective Small-Batch Production

Using affordable plastics or composites makes short-run production possible without high upfront costs. Companies can test new designs before investing in full-scale manufacturing.

5. Wide Material Options for Different Needs

From flexible nylon to strong titanium, each material serves a unique purpose. Clients can balance cost, durability, and aesthetics depending on their project.

6. Reduced Waste and Sustainability

3D printing is additive, meaning it only uses the material needed to build the part. Options like biodegradable PLA also support eco-friendly manufacturing.

Conclusion

When considering what materials can be used in 3D printing, the options are wide from affordable plastics for prototypes to resins for high detail and metals for strength and durability. Each material offers unique benefits, whether you need lightweight parts, smooth finishes, or industrial-grade performance.

But just as important is knowing whats materials cannot be used in 3d printing. Certain plastics like PVC, materials with unstable melting points, or specific high-temperature metals are unsuitable because they can cause printing failures, release toxic fumes, or require processes beyond standard 3D printing capabilities.

At The Monster Builder, if you’re unsure which material suits your project, our team is here to help. We provide expert services from 3D printing to full metal fabrication to ensure your parts are made with the right materials and the highest quality standards.