FDM vs SLA 3D Printing Comparison

FDM is affordable, durable, and ideal for large functional parts, while SLA delivers higher resolution, smoother surfaces, and is best for detailed cosmetic models, prototypes, and applications requiring precision.

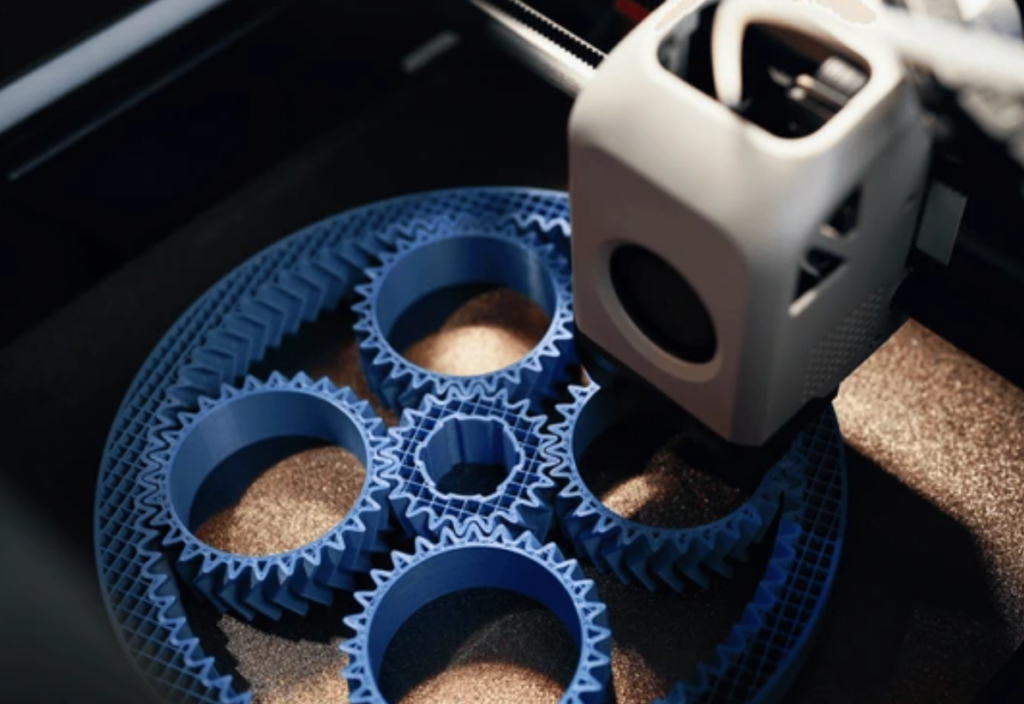

What is FDM 3D Printing?

FDM (Fused Deposition Modeling) also called FFF (Fused Filament Fabrication) is the most widely used type of 3D printing. It works like a precise “hot glue gun,” melting plastic filament and depositing it layer by layer to form a part.

In addition, FDM printers are popular in schools, universities, and design studios because they are simple to operate and affordable. In business settings, engineers often use FDM for fast proof-of-concept models, functional brackets, fixtures, and housings before moving on to production-ready methods.

Common materials include PLA, ABS, PETG, Nylon, and TPU. These plastics are tough enough for real-world testing, making FDM an excellent choice for durable prototypes at low cost. However, FDM parts show visible layer lines, and achieving watertight or isotropic strength can be challenging compared to resin or industrial printing.

In Singapore, FDM 3D printing is the go-to solution for low-cost prototypes and functional parts where budget and speed are more important than surface smoothness.

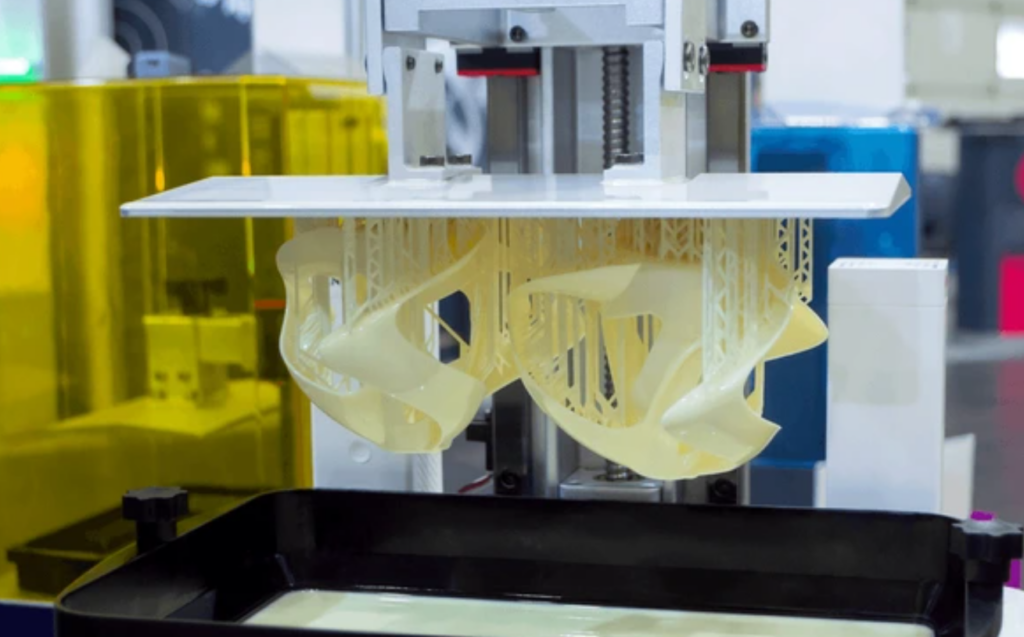

What is SLA 3D Printing?

SLA (Stereolithography) also known as resin 3D printing. Engineers developed SLA in the 1980s, making it the first 3D printing technology. Instead of melting filament, SLA uses a laser or projected light to cure liquid resin into thin, solid layers.

Modern SLA printers achieve exceptional accuracy and surface finish, often matching the look of injection-molded plastics. They are widely used in cosmetic prototypes, dental and medical models, jewellery casting masters, and detailed components where smoothness and precision are critical.

Resins range from standard to clear, tough, flexible, or castable. This variety allows SLA parts to simulate production plastics, making them ideal for functional prototyping or even small-batch end-use parts.

In Singapore, SLA 3D printing is preferred for client-facing prototypes, high-detail models, and applications where precision and aesthetics matter more than raw toughness.

FDM vs SLA 3D Printing

Both technologies have a place in modern design and manufacturing. The challenge for businesses in Singapore is understanding which one fits their project best.

Materials: Plastic Filament vs Liquid Resin

The difference in printing methods also shapes the materials you can use.

With FDM, you’re working with thermoplastics like PLA, ABS, PETG, Nylon, and TPU. These are familiar engineering-grade plastics, often chosen for their durability, heat resistance, or flexibility. Some filaments are reinforced with carbon fiber or glass for extra strength, making them ideal for functional prototypes and even end-use parts.

SLA, by contrast, uses resins, liquid photopolymers that harden under light. Options range from standard resins for cosmetic models, to clear resins for transparent parts, to castable resins for jewellery molds. Specialized resins, such as biocompatible materials, make SLA particularly valuable in the dental and medical industries.

If you need a tough bracket for a manufacturing jig, FDM is the better fit. If you need a flawless prototype of a consumer product, SLA is the clear winner.

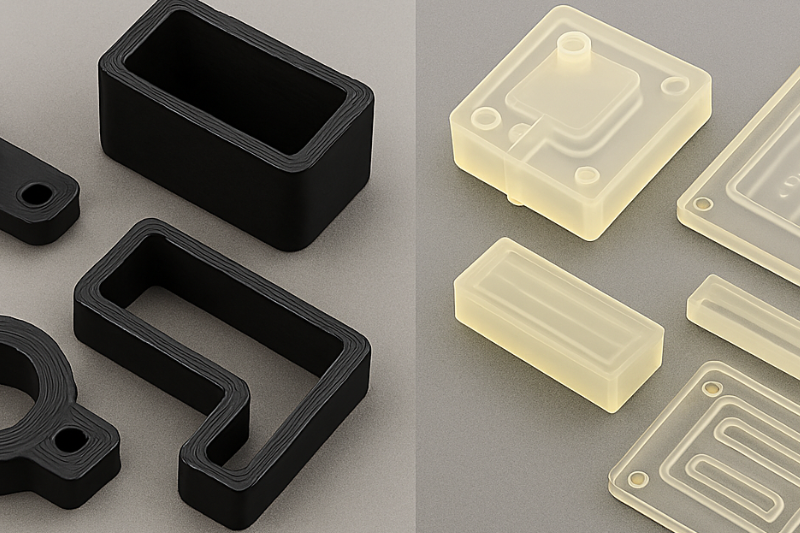

Print Quality and Surface Finish

FDM parts typically show visible layer lines, especially on curved surfaces. While sanding, vapor smoothing, or painting can improve the finish, the raw prints are more utilitarian than polished.

SLA parts, however, emerge with a glassy-smooth surface straight out of the printer. Fine details, thin walls, and sharp edges are faithfully reproduced, which is why SLA is the go-to choice for cosmetic prototypes, figurines, and detailed presentation models.

In simple terms, FDM prioritizes function, SLA prioritizes form.

Build Volume: Size vs Precision

FDM printers can be scaled up significantly. Large-format machines are used to print furniture pieces, industrial housings, or oversized prototypes.

SLA printers are limited by the size of their resin tanks. While they excel at small, intricate models, you must split large parts into sections and bond them together.

If your project requires a large prototype in one piece, FDM is the better choice. If it requires microscopic details, SLA is unmatched.

Applications in Singapore

Both technologies are widely used across industries in Singapore.

FDM: Factories and engineering firms use it for jigs, fixtures, and housings. Robotics and electronics teams rely on it for brackets and casings. Schools and universities use it for teaching and concept models.

SLA: Dental labs create surgical guides and study models. Jewellery designers print casting masters. Product design firms use it for client-facing prototypes where appearance is just as important as function.

Many Singaporean business use both technolgy like FDM for rough functional prototypes, SLA for final presentation models before scaling to CNC machining or plastic injection molding.

FDM & SLA 3D Printing Cost in Singapore

In Singapore, FDM 3D printing is generally more affordable than SLA 3D printing because filaments are cheaper than resins and the process requires less post-processing.

Typical price ranges:

- FDM 3D printing cost in Singapore: SGD $30 – $80 per part

- SLA 3D printing cost in Singapore: SGD $60 – $150 per part

To conclude, FDM is best for low-cost, functional prototypes and larger parts, while SLA is chosen for high-detail, cosmetic, or precision models where surface finish matters.

| Factor | FDM (Fused Deposition Modeling) | SLA (Stereolithography) |

|---|---|---|

| Technology | Extrudes melted filament | Cures liquid resin with light |

| Accuracy | ±0.2–0.5 mm | ±0.05–0.1 mm |

| Surface Finish | Visible layer lines | Smooth, near injection-molded |

| Materials | PLA, ABS, PETG, Nylon, TPU, composites | Standard, clear, tough, castable, dental resins |

| Build Volume | Very large prints possible | Smaller, resin-limited |

| Cost (Singapore) | SGD $30 – $80 | SGD $60 – $150 |

| Best For | Functional prototypes, fixtures, brackets | Cosmetic models, jewellery, medical models |

Which One You Should Choose?

At The Monster Builder, our FDM 3D printing isn’t limited to the basics. We support over ten varieties of plastic filaments, ranging from budget-friendly PLA and durable ABS to high-performance carbon-fiber and specialty blends ideal for functional parts like jigs and mechanical components.

On the flip side, our SLA services exploit a different realm of materials. From clear and standard resins suited for aesthetic prototypes, to tough or castable options tailored for dental guides or jewellery masters, each material is carefully matched to your product’s purpose and finish.

We also make sure clients understand the limits, not all plastics or exotic materials work with FDM or SLA and that’s a topic we cover in full on our “What Materials Cannot Be Used in 3D Printing” page, helping you avoid costly design dead-ends.