3D Printing in Dentistry - LCD vs DLP vs SLA

Dental technology in Singapore is moving fast. From same-day crowns to fully digital orthodontic workflows, 3D printing is no longer optional. Choosing between LCD, DLP, and SLA printers can feel overwhelming but each plays a unique role in modern clinics and dental labs.

How Does 3D Printing Work in Dentistry?

3D printing in dentistry combines digital design with additive manufacturing to create dental appliances, models, and restorations that are accurate to within microns. Instead of relying on traditional manual impressions and stone models, clinics now use a fully digital workflow:

Step 1: Intraoral Scanning

The dentist scans the patient’s mouth using an intraoral scanner. This produces a 3D digital file (STL/OBJ) that captures teeth, gums, and bite alignment with high accuracy. Digital scanning reduces errors compared to manual impressions and improves patient comfort.

Step 2: CAD Design

Using CAD (computer-aided design) software, the dentist or lab technician designs the dental device like crowns and bridges for prosthodontics, orthodontic aligners or retainers, surgical guides for implant placement. This stage allows virtual adjustments before manufacturing, minimizing chairside errors.

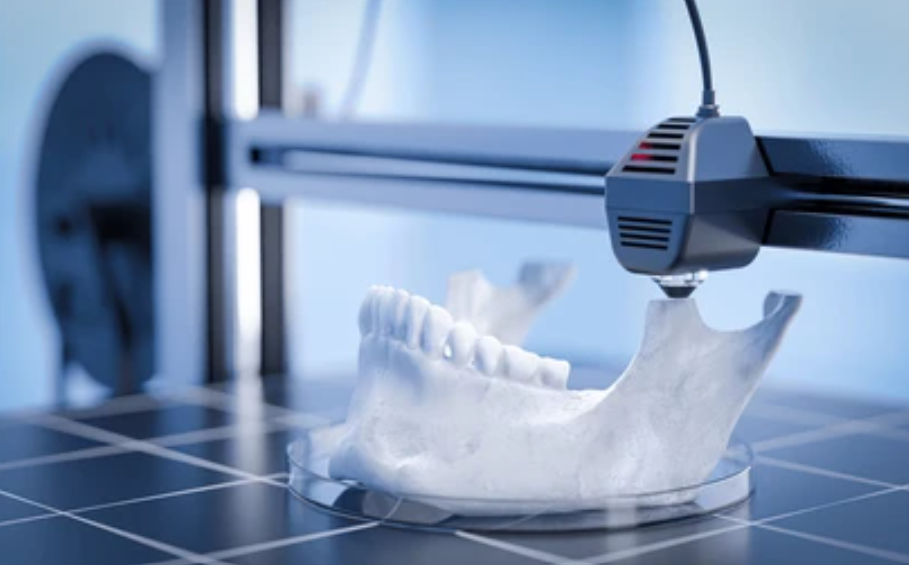

Step 3: 3D Printing

The design is sent to a 3D printer (LCD, DLP, or SLA) where resin is cured layer by layer.

Choice of printer technology depends on application:

- SLA: ultra-smooth crowns, implant models

- DLP: fast aligner and surgical guide production

- LCD: affordable diagnostic and study models

Clinic often ask how difference between SLA and FDM 3d printing.

Step 4: Post-Processing

Once printed, parts undergo resin washing, uv curing to harden the material fully and finishing such as polishing, colouring or add clasps. For castable resins, the print can be used to make metal frameworks via investment casting.

Step 5: Clinical Application

Final parts are tested for fit and accuracy before delivery to the patient. For exmaple, a 3D printed aligner helps correct teeth alignment gradually.

LCD, DLP and SLA – Core Differences

LCD 3D Printing in Dentistry (Masked Stereolithography)

An LCD panel masks and exposes light to cure each layer. Typically 50–100 microns; acceptable for dental models and non-critical applications. Best for orthodontic models, diagnostic tools, educational use.

Advantages:

- Affordable entry cost

- Easy to operate

- Good resolution for basic models

Limitations:

- Shorter LCD lifespan (screen wear)

- Accuracy varies by brand and resin

- Slower than DLP for batch printing

DLP 3D Printing in Dentistry (Digital Light Processing)

A digital projector flashes entire resin layers at once. Consistently 25–50 microns, making it suitable for precise dental devices. Best for clear aligners, surgical guides, temporary crowns and bridges.

Advantages:

- Fastest print speeds (layer-at-once curing)

- High throughput for busy clinics/labs

- Excellent balance of cost vs precision

Limitations:

- Higher upfront cost

- Limited build size vs some SLA machines

- Requires projector maintenance/replacement

SLA 3D Printing in Dentistry (Stereolithography)

A UV laser traces each layer of the print. Extremely high often 25–50 microns, with the smoothest surfaces. Best for crowns, bridges, implant models, castable patterns for metal frameworks.

Advantages:

- Gold standard for precision and repeatability

- Wide resin compatibility (biocompatible, castable, flexible resins)

- Excellent for complex geometries and fine details

Limitations:

- Slowest of the three methods

- Higher operating and material costs

- More intensive post-processing

Cost vs ROI Analysis

For many dental clinics and labs in Singapore, investing in an in-house 3D printer can seem attractive at first, but the true costs quickly add up. A professional SLA or DLP printer alone can cost between SGD $7,000 and $25,000, and that does not include the recurring expenses of biocompatible resin, curing and washing stations, routine maintenance, and staff training.

By outsourcing to The Monster Builder, clinics avoid all these upfront investments and instead pay only for what they need. A diagnostic model may cost little. This flexible, pay-per-part model keeps cash flow healthy, eliminates downtime, and ensures consistent accuracy using industrial-grade equipment.

For example, an orthodontic clinic printing 20 aligner models a month would spend roughly SGD $800 with outsourcing, compared to an upfront investment of over SGD $12,000 plus monthly material and maintenance costs if they purchased a DLP printer. Similarly, an implant specialist ordering 10 surgical guides monthly pays SGD $1,500, but avoids the SGD $20,000+ required for a professional SLA setup and the two-year wait to break even.

Try our 3D printing services while your clinic benefits from fast turnaround, reliable precision, and no hidden costs.

Conclusion

3D printing in dentistry is no longer just a trend. It has become a core technology for modern clinics and labs in Singapore. Whether you choose LCD for affordable models, DLP for high-speed aligner and surgical guide production, or SLA for the gold standard in precision crowns and implants, each technology plays an important role in dental workflows.

For many clinics, however, investing in expensive hardware and materials can delay ROI. That’s why outsourcing to The Monster Builder offers a smarter path.

With our industrial-grade 3D printing services including SLA 3D printing, FDM 3d printing, you gain immediate access to speed, accuracy and biocompatible materials without the heavy upfront costs.