Carbon Fiber: What It Is, Types, Laser Cutting & 3D Printing

Carbon fiber is a lightweight yet exceptionally strong material that’s reshaping industries from aerospace to automotive to consumer products. Known for its high strength-to-weight ratio, corrosion resistance, and modern appearance, carbon fiber is now common in everything from sporting equipment to industrial fixtures.

This guide explains what carbon fiber is, how it’s made, the types available, and its key applications in Singapore’s manufacturing scene. Whether you’re an engineer, designer, or business owner, understanding carbon fiber helps you choose the right material for your next project.

What Is Carbon Fiber?

Carbon fiber is a lightweight, high-strength material made from very thin strands of carbon atoms bonded together and combined with resin to form strong composite structures.

It offers an exceptional strength-to-weight ratio, stiffness, and resistance to corrosion, making it ideal for aerospace, automotive, sporting goods, and industrial manufacturing. In practice, carbon fiber appears as woven cloth, chopped fiber mixed with plastics, or pre-formed composite sheets.

A drone manufacturer in Singapore replaced aluminium landing struts with carbon fiber, reducing weight by 40% while increasing stiffness.

What Is Carbon Fiber Made Of?

Most carbon fiber starts from polyacrylonitrile (PAN) or pitch. It undergoes:

- Stabilization: heating the precursor to 200–300 °C.

- Carbonization: heating to 1,500–3,000 °C to form long chains of carbon atoms.

- Surface treatment & sizing: improves bonding with resin.

The resulting fibers can be woven into cloth, chopped, or mixed with resin to form composites.

We often CNC machine aluminium inserts and then over-mold with carbon-fiber-reinforced plastic using plastic injection molding to combine metal strength with composite lightness.

Types of Carbon Fiber

Carbon fiber comes in several types based on fiber grade (strength/stiffness), precursor (PAN or pitch), tow size, and product form (fabric, prepreg, chopped or continuous). Each type suits different performance and manufacturing needs.

Performance grade (strength vs stiffness)

- High-Strength (HS) — maximizes tensile strength, good fatigue resistance. Used for automotive panels, bike frames, sporting goods, general structures.

- Intermediate-Modulus (IM) — balanced strength and stiffness. Used for drones, robotics arms, machine brackets, industrial fixtures.

- High-/Ultra-High-Modulus (HM/UHM) — very stiff, lower strain to failure (more brittle). Used for aerospace spars, precision stages, tripods, high-end racing parts.

Precursor

- PAN-based (most common): balanced cost, strength, and processability.

Used for nearly all consumer/industrial applications. - Pitch-based: very high modulus, high thermal/electrical conductivity; higher cost. Used for satellites, heat spreaders, specialty electronics.

Tow size

- 1K–3K tow (very fine): tight weave, smooth cosmetic finishes, sharp corners. Used for visible surfaces, thin laminates, small precision parts.

- 6K–12K tow (standard): good balance of drape and layup speed. Used for general structural panels, housings.

- 24K–60K tow (heavy): fast layup, lower cost per area, less drapable. Used for large panels, tooling faces, non-cosmetic structures.

Weave / fiber orientation

- Unidirectional (UD): fibers run in one direction; maximum stiffness/strength along that axis. Used for beams, spars, robot arms (align fiber with load).

- Plain weave: tight crimp, stable fabric, good for small parts. Used for covers, brackets, instrument panels.

- Twill (e.g., 2×2 twill): iconic “carbon look,” better drape over curves. Used for fairings, shells, consumer products with visible weave.

- Multiaxial (±45°, 0/90/±45): stacked orientations for quasi-isotropic behavior. Used for panels that see loads from multiple directions.

Product form

- Dry fabric + epoxy (hand layup / vacuum bag / infusion): add CNC Machining for trimming and holes, pair with Steel Fabrication or Aluminium Sheet Fabrication for hybrid assemblies.

- Chopped/short fiber thermoplastics (PA-CF, PETG-CF, PC-CF), used for FDM 3D printing of stiff, lightweight brackets, jigs, fixtures.

- Milled/flake fiber compounds (injection-moldable): use Plastic Injection Molding of structural housings, gears, clips where weight saving matters.

If you’re considering different fiber types, check our guide on 3D printing materials and applications to see how composites compare.

What Does Carbon Fiber Do?

Carbon fiber provides high strength and stiffness at very low weight, making it ideal for building lightweight, durable parts across aerospace, automotive, sporting goods and industrial manufacturing.

It reduces weight while maintaining or improving structural performance, resists corrosion, and can conduct heat or electricity depending on the design.

A local robotics startup requested carbon-fiber end-effectors for its robot arms, cutting total arm weight by 25%, boosting speed and reducing power draw.

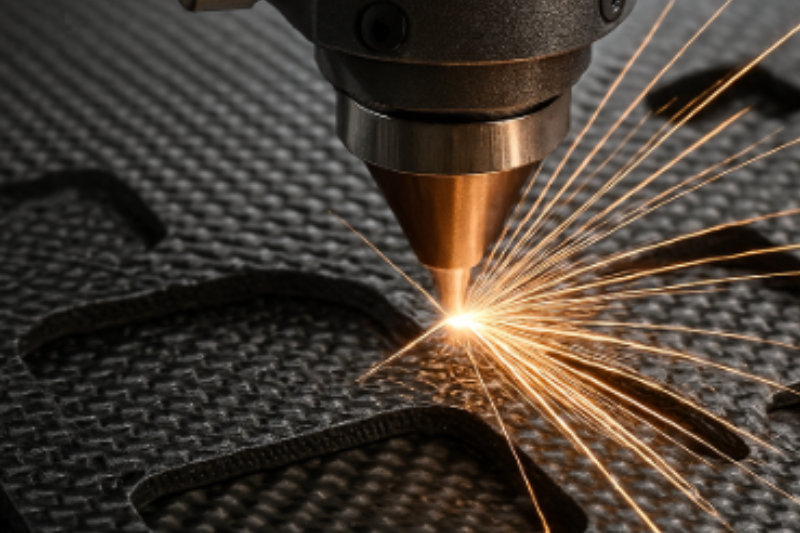

Laser Cut Carbon Fiber

Laser cutting can produce clean shapes from uncoated carbon-fiber sheets. However, the process releases hazardous fibers and resin fumes.

Our approach:

- We validate each sheet type before laser cutting.

- We use industrial fume extraction and PPE to ensure safety.

- For epoxy-rich laminates, we use CNC routing with diamond-coated tools to prevent fraying, and integrate the parts into our metal fabrication workflows.

We produced custom carbon-fiber gaskets for an electronics client using CNC routing to achieve smooth edges without burning the resin.

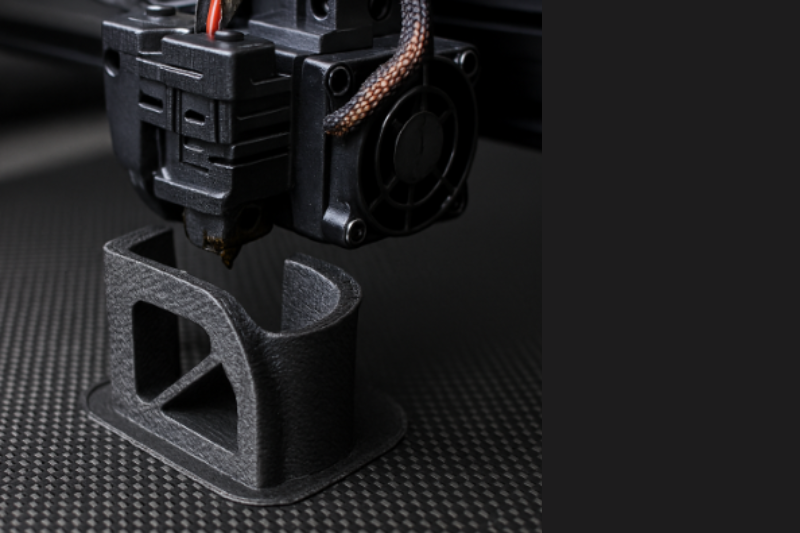

Carbon Fiber 3D Printing

Carbon fiber filaments are one of the strongest materials used in 3D printing. Most carbon-fiber 3D printing happens via FDM using chopped carbon-fiber filaments. For maximum strength, continuous-fiber printers inlay long strands alongside thermoplastics (specialized systems).

Advantages:

- Stiffer, lighter prototypes compared to standard thermoplastics.

- Functional fixtures for production environments.

- Hybrid parts combining aluminium sheet fabrication inserts with carbon fiber shells.

A client requested custom drone propeller mounts printed in Nylon-CF filament. We achieved a 60% weight saving with no loss of strength compared to solid ABS parts.

SLA 3D printing is ideal for ultra-smooth resin parts but not for carbon-fiber-reinforced builds.

Conclusion

At The Monster Builder, we work with carbon fiber every day from CNC machining and laser cutting to carbon-fiber-reinforced 3D printing and plastic injection molding.

If you’re planning a project that could benefit from carbon fiber, our engineers can guide you on material selection, manufacturing process, and cost-effective production methods. Contact The Monster Builder today to discuss your ideas or request a quote.