Chamfer vs Fillet: Know the Differences & Uses

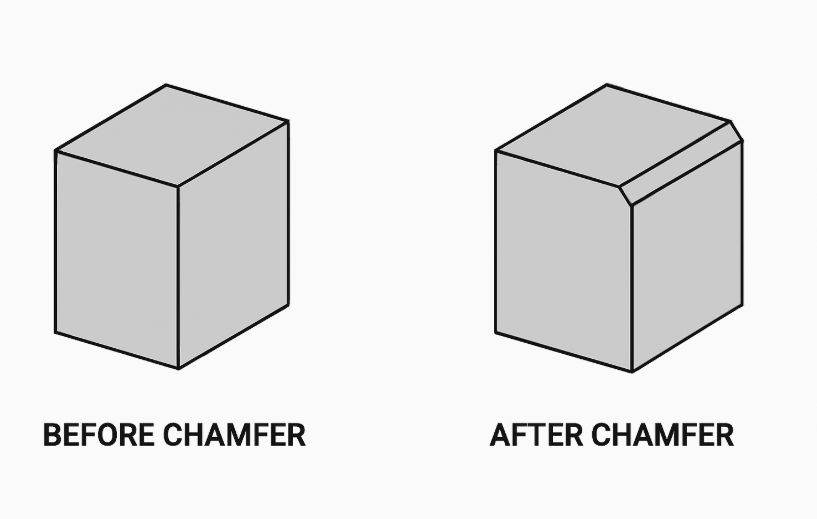

What is a Chamfer?

A chamfer is a flat, angled cut that removes a sharp 90-degree edge or corner from a part. It creates a beveled surface, commonly at 45° to improve safety, ease assembly, and enhance appearance. Chamfers are widely used in CNC machining, sheet-metal fabrication, 3D printing, and plastic molding.

Design and Purpose of Chamfer

- Ease of assembly: Chamfers help guide mating parts (e.g. pins, bolts) into holes and assemblies.

- Edge safety and handling: They remove sharp edges, reducing risk of cuts or damage during handling.

- Cost efficiency: Chamfers are simpler tools to apply (fewer passes, simpler cutter paths), which typically leads to lower manufacturing time & cost.

- Aesthetic or functional transitions: Chamfers can soften visual edges without the roundness of fillets; they also help avoid interference in assemblies.

Limits and Trade-offs

- Chamfers offer less stress relief than fillets, particularly under cyclic loads or fatigue. Sharp angles still concentrate stress more than smooth radii.

- Coating or painting over sharp angled edges: coatings tend to be thinner and more prone to damage at chamfered edges compared to rounded ones.

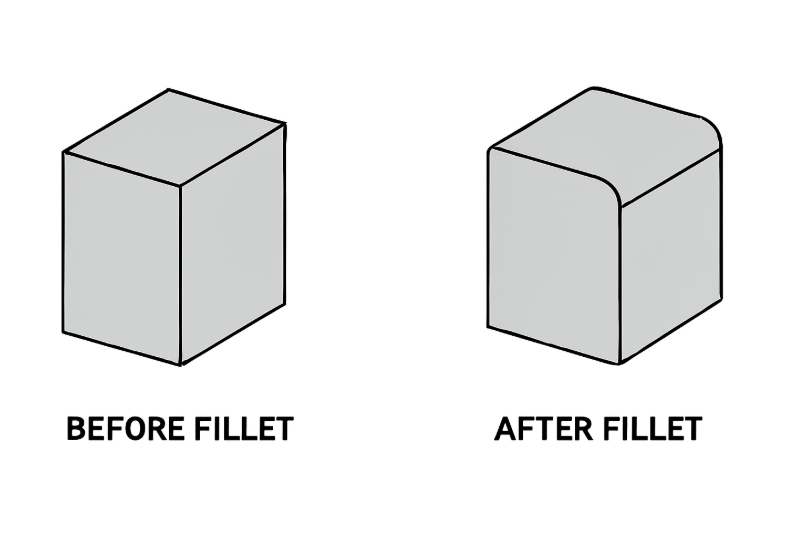

What Is a Fillet?

A fillet is a rounded or curved transition between two surfaces or edges, replacing a sharp corner with an arc of a defined radius. Fillets reduce stress, improve material flow, and enhance ergonomics. They are common in CNC machining, sheet-metal fabrication, 3D printing, and plastic injection molding.

Design and Purpose of Fillet

- Stress reduction: Fillets distribute stress over a wider area, substantially reducing stress concentration at corners. Critical in load bearing or fatigue-prone parts.

- Improved material flow: In processes such as casting, plastic injection molding, or even in fluid or airflow designs, rounded edges promote smoother flow and reduce turbulence or disruptions.

- Ergonomics and aesthetics: Fillets make parts safer to touch or hold; visually “softer” edges are perceived as higher quality.

- Surface finishing / coatings: Rounded edges tend to yield more uniform coatings (paint, powder coat, anodise), and less risk of peeling or thinner coverage.

Limits and Trade‐offs

- Fillets typically cost more to machine (especially internal fillets), require more complex tooling (ball-end mills, corner rounding tools), more careful CAD/CAM paths, multiple passes.

- Larger radii may interfere with other features or tolerance constraints in tight assemblies. Designers must ensure sufficient clearance.

- In 3D printing, especially SLA or FDM on fine features, very small fillet radii may not print cleanly depending on layer thickness and printer resolution.

Differences Between Edge Styles

Chamfers and fillets differ in shape, purpose, and performance. A chamfer is a flat, angled cut that removes a sharp edge to ease assembly and reduce injury risk. A fillet is a smooth, rounded transition that distributes stress and improves material flow. Chamfers are quicker and cheaper to machine, while fillets offer greater strength and a softer appearance.

| Feature / Aspect | Chamfer (Beveled Edge) | Fillet (Rounded Edge) |

|---|---|---|

| Shape | Flat, angled cut (commonly 30°–60°, often 45°) | Smooth, curved transition with defined radius (e.g. R2) |

| Primary Purpose | Eases assembly, removes sharp edges, reduces injury risk | Distributes stress, improves material flow, enhances ergonomics |

| Manufacturing Complexity | Simple to machine with standard cutters (lower cost, faster) | Requires ball-end or radius tools (higher cost, slower) |

| Best Use Case | Crisp, technical edge appearance | Soft, premium, ergonomic appearance |

| January | Lead-ins, edge breaks, clearance in CNC & sheet-metal fabrication | High-load parts, molded components, ergonomic products |

When to Use Each Type

Choosing between chamfer and fillet isn’t “one size fits all.” Factors to consider include material, manufacturing process, cost, part function, finish, safety, aesthetics. Here are guidelines:

When to Use a Fillet

- Parts subject to high mechanical loads or fatigue (shafts, joints, brackets)

- Areas where internal stress concentration matters (e.g. rib roots, internal corners)

- When ergonomics or human touch is important (handles, handheld devices)

- For superior coating or paint durability, or where finish quality is premium

- In injection molding or casting, where smooth transitions improve flow and reduce molding defects

When to Use a Chamfer

- Where cost and speed are important, and the load / stress is moderate

- For assembly-help features (lead-in chamfers, fastener alignment, mating surfaces)

- Where tight tolerance or space doesn’t allow large radii

- For sheet metal fabrication edges where bending or welding requires bevels or clearance

- When finishing/sharp-edge removal is needed but a full fillet isn’t justifiable

When To Use Both / Hybrid Designs

- Use fillets in high-stress areas and chamfers elsewhere

- External edges that users touch than fillet; internal clearances or mating features then chamfer

- Use small chamfers to break edges everywhere (for safety), with fillets added where needed for performance

Real-World Examples & Best Practices

- In CNC Machining of steel parts that bear heavy loads, internal fillets of radius R1-R5 mm (depending on size) are common to avoid fatigue cracks.

- In Sheet Metal Fabrication, chamfers are used to facilitate bending, welding, and clearance, especially in corners where material may fold or weld beads will interfere.

- In 3D Printing (FDM / SLA): small fillet radii less than twice layer height may not render well; heavy reliance on part orientation to avoid stair-stepping artifacts.

- In Plastic Injection Molding, fillets are often required around corners to avoid sink marks and improve material flow; deep sharp corners can cause stress, air traps.

Conclusion

Choosing between chamfers and fillets can dramatically affect the performance, cost, and appearance of your parts. Chamfers are ideal for quick edge breaks, assembly guides, and lower-cost production, while fillets excel in high-stress areas, ergonomic parts, and improved material flow. By understanding these differences, you can design stronger, safer, and more efficient components.

Our Singapore-based team combines CNC machining, sheet-metal fabrication, SLA & FDM 3D printing, and plastic injection molding under one roof. That means you get expert advice on which edge treatment works best for your material, process, and budget. Talk to us today about your next project and discover how we can help you achieve stronger, safer, and more cost-effective parts.