3D Printing vs Additive Manufacturing: Any Differences?

3D printing and additive manufacturing can do more than just speed up production, and they can reshape entire workflows. This guide breaks down how they work, where they differ, and why it matters for anyone involved in design, prototyping, or production in Singapore.

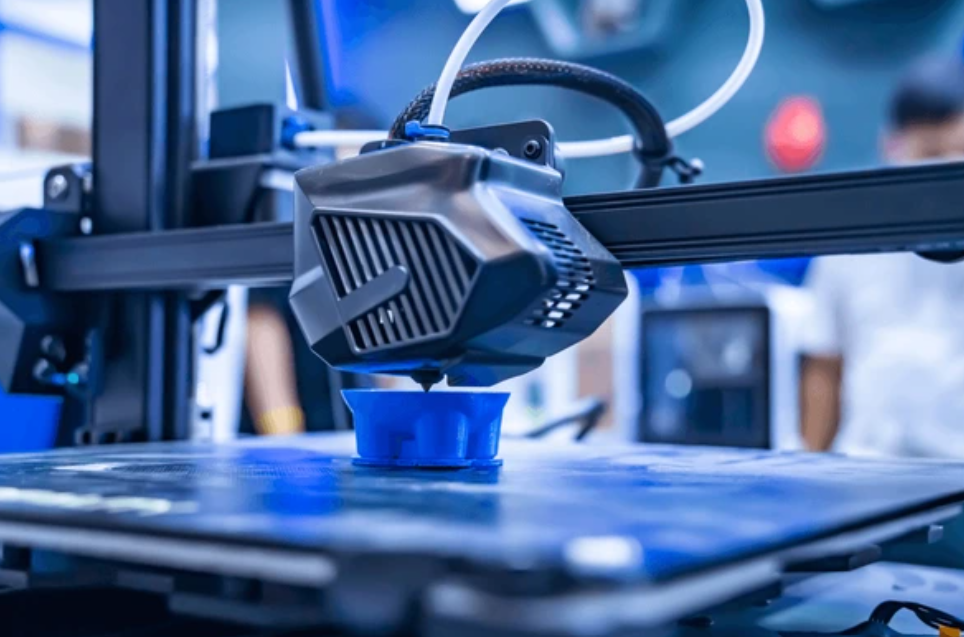

What Is 3D Printing?

3D printing is a manufacturing process that creates three-dimensional objects by adding material layer by layer from a digital design. Also called additive manufacturing, it allows fast prototyping and small-batch production using plastics, resins, or metals, making complex shapes without traditional tooling.

Common processes: Fused Deposition Modeling (FDM) / Fused Filament Fabrication (FFF), Stereolithography (SLA), Resin photopolymer printing, often polymer-based.

What Is Additive Manufacturing?

Additive manufacturing is an industrial production process that builds three-dimensional objects layer by layer from digital models. Often called industrial 3D printing, it uses advanced materials such as plastics, composites, or metals to create complex, high-performance parts without traditional molds or tooling.

Materials & Processes: Includes high performance or industrial materials: metals (aluminum, steel, titanium), composites, ceramics; industrial AM processes such as selective laser melting (SLM), direct metal laser sintering (DMLS), electron beam melting (EBM), binder jetting, etc.

Industrial Usage: Used for end-use parts, small batches of functional components, complex geometries not feasible with traditional subtractive methods.

Key Differences: 3D Printing vs Additive Manufacturing

Although the terms are often used interchangeably, 3D printing and additive manufacturing serve slightly different purposes. 3D printing usually refers to smaller-scale, polymer-based processes ideal for rapid prototyping and low-volume parts, while additive manufacturing encompasses a broader range of industrial, production-grade technologies including metals, composites, and certified processes for end-use components.

Understanding these differences helps businesses choose the most cost-effective and technically suitable method for their project.

| Feature | 3D Printing | Additive Manufacturing |

|---|---|---|

| Scale & Volume | Low to medium volume (prototypes, concept, small batches) | Medium to high (end-use parts, small to moderate series production) |

| Machine & Capital Cost | Lower machine purchase cost (desktop or semi-industrial), lower ancillary cost | High capital investment, advanced machines, auxiliary systems (powder handling, inert gases, post-processing) |

| Material Cost & Variety | Predominantly polymers/resins, some composites; fewer metal options | Broad material range, including metals & specialty alloys; higher material cost per kg, especially for high-performance metals |

| Tolerances & Mechanical Properties | Lower precision and strength (depends on process); may be acceptable for non-structural parts | Tighter tolerances, better mechanical performance, more consistent quality; required for functional and certified parts |

| Surface Finish & Post-Processing | Post-processing often simpler for visuals, but still needed (support removal, sanding, resin curing) | More intensive post-processing (heat treatment, powder removal, polishing, certifications) |

| Cost per Part | Lower when volumes are small, less material, simpler machines | Higher fixed and operating costs, but cost per part decreases with volume (economies of scale) |

Types of AM & 3D Printing Processes

- FDM / FFF (Fused Deposition Modeling): Melts and extrudes thermoplastic filament to build parts layer by layer; ideal for low-cost prototypes and functional parts.

- SLA / DLP (Stereolithography & Digital Light Processing): Uses light to cure liquid resin into solid layers; delivers high precision and smooth finishes for aesthetic or detailed parts.

- SLS (Selective Laser Sintering): Fuses powdered polymers with a laser; creates durable, complex shapes without support structures.

- Powder Bed Fusion (SLM / DMLS for Metals): Uses lasers to melt metal powders for strong, end-use components in aerospace, medical, and tooling.

- Binder Jetting: Deposits a liquid binding agent onto a powder bed (metal, sand, or ceramics); faster build times for larger parts but needs post-sintering.

- Directed Energy Deposition (DED): Blows powder or wire into a focused energy source to add material; ideal for repairs or large components.

- Material Jetting / Multi-Jet Printing: Jets droplets of photopolymer that harden under UV light, allowing full-color or multi-material parts.

- Sheet Lamination: Bonds layers of sheet material (metal foils, paper, composites) and cuts them to shape; suitable for low-cost prototypes or large parts.

Each process supports different 3D Printing Materials, tolerances, and costs. Choosing the right technology depends on your part requirements, volume, and performance goals

Advantages and Limitations

Advantages of Additive Manufacturing / 3D Printing

- Design Freedom & Complexity: Internal lattices, conformal cooling channels, complex geometries that are impossible or very expensive with CNC or casting.

- Reduced Material Waste: Compared to subtractive methods (like CNC machining), additive methods only use material where needed.

- Shortened Lead Time: No tooling required for many AM parts; fast changeovers.

- Customization & On-Demand Production: Especially valuable in medical, aerospace, or custom consumer goods.

Limitations & Trade-Offs

- Cost Upfront: High initial cost for industrial AM machines, material costs, and specialized labour.

- Speed & Build Size: Some AM processes are slow for large parts; build volumes may be smaller.

- Material & Mechanical Limitations: Some materials are still challenging (e.g. metals with high density, fatigue life, certification); polymer parts may have weaker anisotropy (weaker between layers).

- Post-Processing Complexity: Especially with metals and high-precision parts, include heat treatment, powder removal, finishing, inspection.

Costs: Additive Manufacturing vs 3D Printing

The cost difference between 3D printing and additive manufacturing can be significant. In Singapore and Southeast Asia, polymer 3D printing (FDM or SLA) typically ranges from SGD 100–800 per part depending on size and finish, making it ideal for prototypes and small runs. Industrial additive manufacturing, especially metal AM, often starts at SGD 800–3,000+ per part due to higher material, machine, and post-processing costs.

Large metal AM machines can cost over SGD 700,000 to SGD 1 million to purchase, while desktop 3D printers may cost SGD 2,000–15,000. As a result, additive manufacturing pays off for complex, high-performance parts or certified end-use components, while 3D printing remains cost-effective for simpler parts and faster prototyping.

Key Cost Factors:

- Machine Investment: Industrial AM machines = SGD 700k–1M+ vs. desktop 3D printers = SGD 2k–15k.

- Materials: Engineering plastics/resins = SGD 50–150 per kg vs. metal powders = SGD 100–600+ per kg.

- Post-Processing: Metal AM needs heat treatment, powder removal, machining, inspections, adding hundreds per part.

- Volume & Complexity: Low volumes favor polymer 3D printing; high volumes or highly complex parts justify additive manufacturing.

- Hybrid Approach: Combining 3D printing with CNC machining or Metal Fabrication can reduce cost and improve tolerances.

When to Use AM vs 3D Printing

Here are some decision criteria / checklist to guide clients and engineers:

- Volume needed: If only a few prototypes or custom pieces, 3D printing (polymer or resin) is cost-effective. If you need dozens or hundreds of functional parts, AM or traditional methods may be better.

- Material and mechanical properties: For load bearing, high strength, regulated use (medical, aerospace), metal AM or hybrid + CNC or steel fabrication may be necessary.

- Geometry complexity: If part has internal channels, complex surfaces, lattice structures, AM wins. For simpler geometries, CNC machining or sheet/steel/aluminum fabrication or moulding may be cheaper and faster.

- Surface finish requirements & tolerances: If high surface finish / fine tolerances are essential, SLA resin or high end AM processes + CNC finishing will add cost.

- Lead time / iteration speed: Prototypes need fast turnaround – 3D printing is generally quicker (less tooling). For production, though, traditional methods may benefit from economies of scale.

- Total cost of ownership: Consider not just per-part cost, but machine costs, labour, maintenance, certification, post-processing.

Conclusion

Understanding the differences between 3D printing and additive manufacturing helps you make smarter decisions about cost, quality, and production speed. 3D printing remains ideal for prototypes and small-batch parts, while additive manufacturing excels at complex, high-performance components or certified end-use production.

Whether you need rapid prototyping, hybrid manufacturing, or full-scale production, our Singapore-based team delivers expert advice, fast turnaround, and high-quality results. Contact us today to discuss your project and discover how the right manufacturing approach can save your time, costs and improve your product quality!