What Is Riveting in Metal Work?

Riveting is a permanent fastening method that joins metal parts by inserting a rivet through aligned holes and deforming its tail to clamp the pieces together. Shops use it to assemble thin sheets and enclosures where welding may warp material or where you only have access from one side.

How the Riveting Process Works

Riveting joins parts by inserting a rivet through aligned holes and forming a second head to clamp the stack. Below is a clear, shop-floor flow you can follow for solid and blind (POP) rivets.

Plan the Joint

Select rivet type & material: Solid for max sheet strength (two-side access), blind where only one side is reachable. Confirm grip range, total stack thickness must fall within the rivet’s rated grip (e.g., 1.5–3.0 mm). Match the maker’s chart. As a rule of thumb, hole ≈ rivet shank diameter + 0.1–0.2 mm (metric). Lay out pitch & edge distance, typical pitch 3–6× diameter; edge distance ≈ 2× diameter.

Prepare the Parts

Mark and drill or punch clean, perpendicular holes. Deburr both sides to prevent high spots and false clamp. Dry-fit with a loose Cleco or temporary fastener to keep alignment.

Before drilling rivet holes, confirm how your parts were made, tolerances differ if they were laser cut vs cnc milled, which affects hole quality and fit.

Insert the Rivet

Push the rivet through the stack so the factory head sits on the cosmetic or higher-load side. Ensure the shank fills the hole and sits square; replace any rivet that fits loosely.

Set the Rivet (2 Common Methods)

Solid Rivet requires access to both sides. Hold a bucking bar against the tail. Use a rivet gun or pneumatic squeezer on the factory head to upset the tail into a shop head. Verify shop-head size (approx. 1.5× shank diameter width; 0.5× height is a common target). Work from the center outward to avoid oil-canning on large panels.

Blind (POP) Rivet is just one-side access. Load the rivet on a hand or pneumatic blind riveter. Squeeze the trigger/handles, the mandrel pulls, expanding the body to clamp the sheets. The mandrel snaps at a preset force; check that the broken stem is either retained (locking types) or removed if specified.

Inspect the Joint

Heads sit flush, no tilt, no cracking, uniform shop-head (solid) or full bulge (blind). No gap between sheets; panel doesn’t rattle. Replace any under-set (loose), over-driven (cracked), or misaligned rivet. Never “double-hit” a blind rivet.

A small chamfer vs fillet choice at the hole can improve fit, reduce paint chipping, and speed assembly.

Types of Rivets and When to Use Them

Rivets come in several forms, each designed for a specific job and access condition. Choosing the right type determines joint strength, durability, and speed of assembly. Below, you’ll see when to use solid, blind, structural, and specialty rivets in common Singapore applications so your riveting process stays efficient and your results last.

Solid Rivets

Best strength for thin metal sheets when you can reach both sides. Suitable for aircraft-style skins, frames, heavy brackets. Needs a rivet gun and bucking bar.

Blind Rivets (POP) – Open-End

Install from one side only. Fast and clean. Uses for enclosures, HVAC ducts, rack panels. Match the grip range to your total sheet thickness.

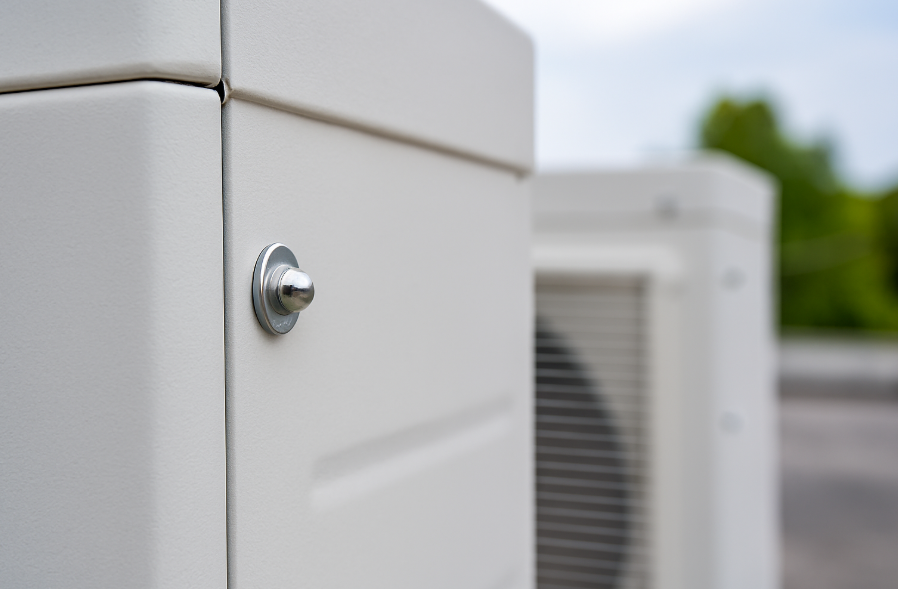

Blind Rivets – Sealed/Closed-End

Keeps water and air from passing through. Suitable for outdoor cabinets, marine fittings, rooftop units. It has extra protection in Singapore’s humidity.

Structural Blind Rivets (Locking Mandrel)

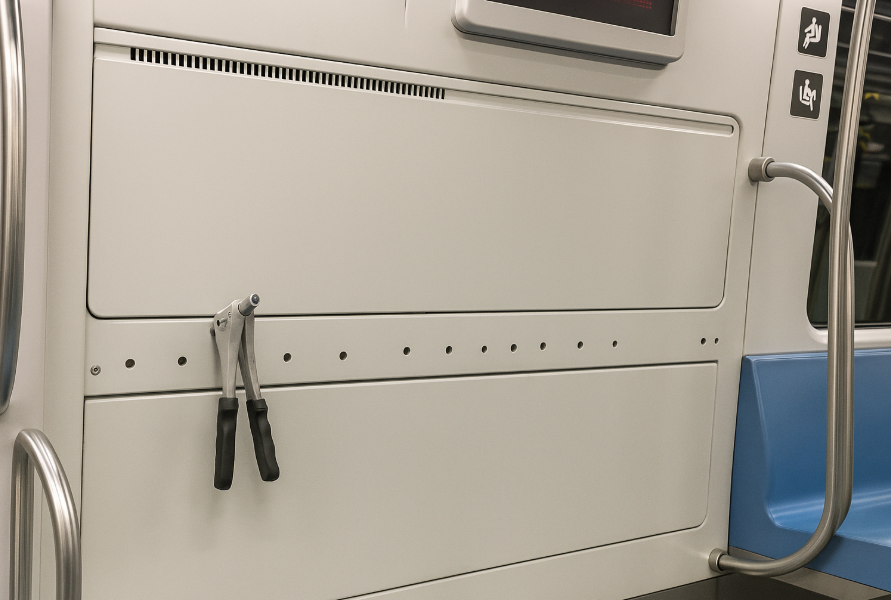

Higher shear/tensile strength with one-side access. Uses for vehicle bodywork, bus/MRT interiors, vibrating equipment.

Mounting brackets onto mild steel C-channels often calls for structural blind rivets to handle vibration and shear loads.

Semi-Tubular / Tubular Rivets

Low setting force for light-duty joints. Best for fixtures, POS displays, consumer products. Not for high structural loads.

Peel / Tri-Fold Blind Rivets

“Peel” to spread load on the blind side. Uses for soft/thin materials like plastics or thin aluminium covers. It prevents pull-through.

Head Styles

Dome/Universal, general purpose, neat finish. Sits flat is ideal for sliding surfaces. Spreads load on soft or thin sheets.

What Is Riveting Used For

Riveting creates permanent, vibration resistant joints in thin metal assemblies when you want clean finishes, minimal heat distortion, and fast installation.

Building and Facilities

- HVAC Ducting and Louvres: Contractors rivet long duct runs and access panels in malls and office towers. Rivets let techs work from one side in tight ceilings and avoid weld burn marks on pre painted ducts.

- Electrical and ELV Enclosures: Fabricators assemble switch boxes and control panels for HDB corridors and plant rooms using blind rivets for clean interiors and quick field repairs.

- Rooftop Equipment Housings: Outdoor pump and chiller cabinets near pools or on rooftops use sealed stainless blind rivets to keep out rain and resist corrosion. For rooftops and marine areas, pair stainless rivets with stainless steel grades suited to Singapore’s climate to limit corrosion.

When you fasten screens or louvers, consider expanded metal for airflow and strength, then secure frames with sealed blind rivets to resist weather.

Transport and Mobility

- Bus and MRT Interior Panels: Maintenance teams secure ceiling panels, brackets, grab rail covers, and signage with structural blind rivets. They hold under vibration and allow one side access inside crowded cabins.

- Lift Car Finishes and Cladding: Installers use countersunk blind rivets to keep surfaces flush and tamper resistant in lift interiors.

Data Centres and Electronics

- Server Racks and Cable Trays: Enclosure makers rivet frames, rails, and EMI shields for fast, repeatable assembly with no weld spatter near sensitive gear.

- Electronics Housings: Small aluminium boxes for IoT gateways and security systems use 3.2 mm blind rivets that set quickly without distorting thin walls.

Manufacturing and Retail Fit Outs

- Fixtures and POS Displays: Semi tubular rivets join brackets and trims on store fixtures for neat looks and fast, low force assembly.

- Appliance and Light Fittings: Peel style blind rivets spread load on thin reflectors and aluminium covers to prevent pull through.

Renewable and Built Environment

- Solar Inverter and Combiner Boxes: Sealed rivets with sealant secure weather exposed covers on rooftops and industrial yards.

- Architectural Cladding and Sun Shades: Countersunk blind rivets keep panels flush and rattle free on facades and linkways.

Riveting vs Welding vs Bolting

Riveting creates a permanent clamp without heat, ideal for thin sheets and one side access. Welding fuses metals for the highest joint continuity but risks distortion and needs two side prep or shielding. Bolting uses threaded fasteners you can remove, best when you need serviceability or thick sections.

Choose riveting when panels are thin, cosmetics matter, or you only have one side access.

Choose welding when you need continuous, high strength joints and can control heat and distortion.

Choose bolting when the assembly must be serviceable or adjustable after installation.

Advantages and Limitations of Riveting

Riveting gives you a fast, repeatable way to join thin metal without heat distortion, making it ideal for enclosures, ducts, and panels where looks and accuracy matter. It works even when you only have access from one side, and it holds up well under vibration.

Still, it’s a permanent method that needs correctly sized holes and isn’t always the best choice for very thick sections or parts that require frequent disassembly.

Advantages

- Installs quickly in thin sheet assemblies

- Works with dissimilar metals and coated/painted parts

- Blind installation possible from one side

- Good fatigue and vibration resistance in sheet joints

Limitations

- Permanent (not designed to remove)

- Requires holes (introduces stress concentrations)

- Not as strong as a well-designed weld in heavy-section joints

- Inventory management: multiple diameters, grip ranges, materials

Riveting relies on material ductility, a ductile sheet forms clean holes and resists cracking as the rivet expands.

Conclusion

Riveting shines in thin-sheet assemblies exactly where our Sheet Metal Fabrication service delivers. We laser-cut, bend, and finish your parts, then apply the right rivet type, grip range, and spacing to assemble clean, rattle-free enclosures, ducts, brackets, and panels for Singapore conditions.

Need sheet metal parts assembled with rivets that last? Get a quote, upload your drawings now. We advise hole size, pitch, edge distance, and material pairing for Singapore’s humidity.