Aluminium Hollow Section Supplier, Uses & Cutting Guide

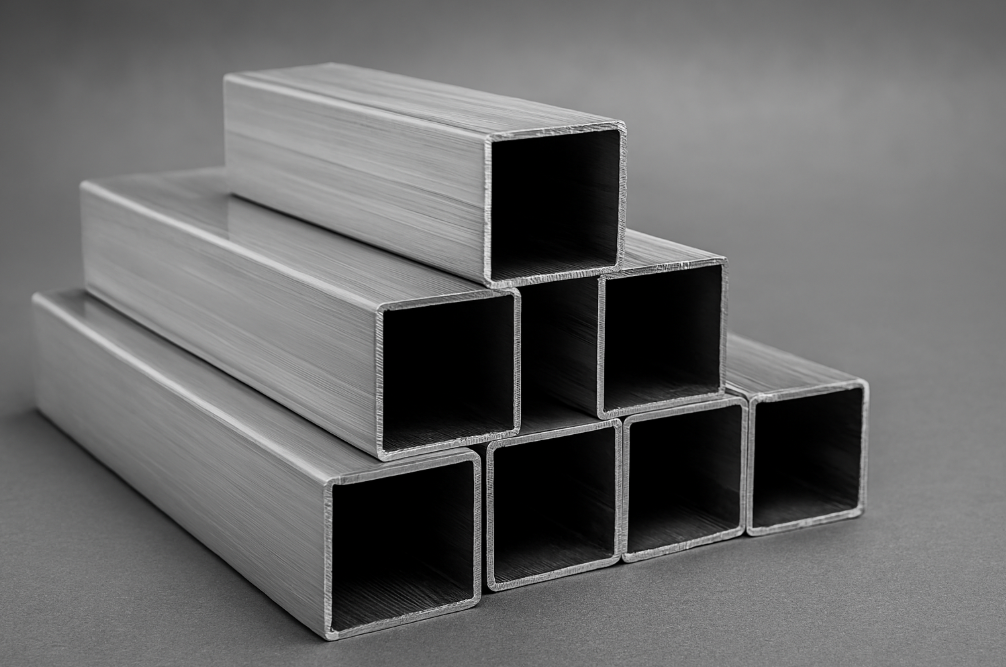

What Is an Aluminium Hollow Section?

An aluminium hollow section is an extruded aluminium profile with a void inside. The most common shapes are square, rectangular, and circular tubes. The hollow core reduces weight while keeping stiffness, so you get easier handling, lower transport cost, and faster installation.

What Is Aluminium Hollow Section Used For?

Aluminium hollow sections serve as lightweight, rigid frames across architectural, retail, and light-industrial builds. Their hollow core cuts weight while keeping stiffness, so installers move faster and support loads safely.

Common Applications

Windows and sliding doors

Use square or rectangular sections as stiles, rails, and mullions. The profiles accept glazing channels and hardware while keeping frames slim.

Shopfront sign boxes and lightboxes

Rectangular sections form the perimeter frame. The cavity neatly hides LED drivers and cables for a clean finish.

Gates, railings, and privacy screens

Hollow sections provide straight, true members that weld or bolt together with minimal sag over spans.

Partitions and display fixtures

Retail racks, exhibition booths, and counters rely on the high strength-to-weight ratio for easy transport and quick assembly.

Façade trims and sun-shades

Architects specify powder-coated sections for louvers, pergolas, and decorative fins that resist corrosion outdoors.

Machine frames and guards

Light industrial benches, cart frames, and safety enclosures benefit from consistent tolerances and easy drilling/riveting.

In Singapore:

HDB/Condo window replacement

Renovation teams often use 6063-T5 rectangular 25×50×1.6–2.0 mm sections for outer frames and mullions. The profile keeps weight low for high-floor installs while meeting typical glazing specs.

Retail LED lightbox at a mall

A 25×50×2.0 mm rectangular hollow section builds a 2 m × 1 m frame. Installers route LED wiring through the cavity and mount acrylic faces; the frame stays rigid yet light enough for wall anchors.

Café pergola at a shophouse

Powder-coated 40×40×2.0 mm square sections create rafters and perimeter beams. The finish withstands sun and rain, and the hollow core reduces overall structural load on the façade.

SME workbench on a production floor

40×40×2.0–3.0 mm square hollow sections bolt to corner brackets and rivnuts to form a sturdy table base that supports small machinery without resorting to heavy steel.

Condo balcony privacy screen

30×30×1.6 mm square sections frame aluminium slats. The lightweight assembly fixes to existing railings with minimal added load and strong corrosion resistance.

What Thickness of Aluminium Section for Windows?

For typical residential window framing, fabricators often work within ~1.2–2.0 mm wall thickness for 6063 series extrusions, increasing thickness for larger spans, heavier glazing, or wind-exposed façades.

Always:

- follow the glazing manufacturer’s load and span tables,

- confirm with your window system supplier, and

- comply with local building requirements (e.g., BCA/HDB specifications for replacements and safety).

Key Benefits

High strength-to-weight

You get rigid frames without the bulk. A 6063/6061 aluminium hollow section supports doors, light façades, and signage while staying easy to lift, transport, and install.

Corrosion resistance in humid, coastal climates

Aluminium forms a protective oxide layer. With anodising or powder coating, sections withstand Singapore’s heat, rain, and salt-laden air. If you’re planning to paint over anodised parts, here is what you need to know. While aluminium resists corrosion naturally, some metals need galvanising for similar protection.

Clean aesthetics and hidden services

The cavity lets you route cables or LED strips for sign boxes and lightboxes, keeping surfaces neat and professional.

Fast fabrication and site efficiency

Cut, drill, rivet, or bolt with standard non-ferrous blades and bits. Hollow walls reduce cutting time and burrs compared with solid bar, speeding up shop and on-site work.

Design flexibility

Square, rectangular, and round profiles come in many outside sizes and wall thicknesses, so you can balance span, load, and look for windows, partitions, and display racks.

Lower structural load

Lightweight frames reduce load on anchors and substrates, useful for HDB/condo renovations where wall loads matter.

Consistent tolerances

Extruded sections deliver uniform dimensions across long lengths, improving fit-up for mitres, corner brackets, and glazing channels.

Sustainable choice

Aluminium is highly recyclable. Using hollow sections cuts raw material use versus solid profiles like aluminium flat bars while maintaining performance.

How to Cut an Aluminium Section

Use a mitre or track saw with a carbide non-ferrous blade. Mark the cut line, clamp the aluminium hollow section firmly, set a slow steady feed, and let the blade work. Support the off-cut, then deburr with a file or deburring tool and finish with fine grit. Wear eye and hand protection.

Quick Step-By-Step

- Measure accurately and mark a fine line with a scribe or tape edge

- Clamp the aluminium section to stop chatter and protect the finish

- Fit a carbide non-ferrous blade with a high tooth count and negative hook angle

- Set speed and feed steadily and let the blade do the cutting

- Support the off-cut to prevent pinching or tear-out at the end of the cut

- Deburr edges using a deburring tool or file, then sand with 240–400 grit

- Dry fit and check squareness before drilling or fastening

Tools That Work Best

- Mitre saw or cold-cut saw for square precise cuts

- Track saw for long straight cuts on large panels

- Bandsaw for thicker walls and curved profiles

- Lubricant stick or wax to reduce heat and burrs

- Soft clamps or scrap pads to prevent clamp marks

How to Hollow Out Aluminium

Mark the cavity, clamp the work, and rough-out with a drill or hole saw before milling/routing to final size. Use non-ferrous cutters, apply cutting wax or light oil, clear chips often, then deburr and finish. For thin walls, step-drill, for plates, pocket with an end mill, for tubes, use a tube-notcher or hole saw.

If you must create a cavity in solid aluminium for a one-off part:

- Drill & Step-drill for simple cable pass-throughs

- Hole saw for larger openings in plate

- Milling on a router/CNC for precise internal cavities

- Broaching/EDM for special shapes (industrial only)

- For frames and architectural work, buying the correct hollow section is faster, lighter, and more cost-effective than machining out solids.

For complex cylindrical parts or hollowing from round stock, CNC Turning Services may offer better efficiency.

Why Buy from a Singapore-Focused Supplier

Aluminium hollow sections give you strong, clean, and corrosion-resistant frames for windows, sign boxes, partitions, and light structures. When your design needs precision pockets, slots, or complex joinery, The Monster Builder delivers with CNC milling for accurate fits and repeatable results. Not sure when to choose milling vs laser? Ask us now.

For panels and frames, our sheet aluminium fabrication covers laser cutting, bending, forming, drilling, tapping, riveting, and finishing options such as anodising and powder coating.

Share your drawing (DXF/DWG or PDF), target alloy and temper (6061 or 6063), outside size and wall thickness, finish, and quantity. We will advise the most efficient build for Singapore conditions, cut your aluminium sections to length, and fabricate the parts you need that is ready to install.