Bulb Plates: Key Applications and Advantages Explained

Bulb plates are integral components in modern shipbuilding and structural engineering. Their unique shape and strength make them a preferred choice for a variety of applications, from ship hulls to bridges. In this guide, we will explore what a bulb plate is, the key properties of bulb plates, and how they are used across industries. Additionally, we will dive into the advantages of using bulb plates and their role in shaping the future of engineering.

What is a Bulb Plate?

A bulb plate is a type of structural steel plate that has a distinctive bulbous profile. It typically features a flat base with a thickened section at the center, which resembles the shape of a bulb, hence the name. This unique design enhances the strength and flexibility of the plate, making it ideal for use in demanding environments.

Bulb plates are most commonly used in shipbuilding, where they are employed to construct the hulls of ships. Their shape contributes to the overall stability and buoyancy of the vessel. In addition to maritime applications, bulb plates are also used in the construction of bridges and other large-scale structural projects.

Key Properties of Bulb Plates

Bulb plates possess several key properties that make them essential in various industries. These properties include:

1. Strength and Durability

Bulb plates are designed to withstand immense stress and pressure. Their robust construction ensures they can handle the heavy loads encountered in shipbuilding and structural engineering. For example, in shipbuilding, the hulls of large vessels rely on bulb plates to maintain their integrity under the strain of waves and rough waters. If you’re looking to understand more about different types of plates, you might want to check out our guide on chequered plate vs plain steel plate, where we dive into the distinct features of each.

2. Corrosion Resistance

Given their application in marine environments, bulb plates are often made from corrosion-resistant materials, such as high-grade steel or alloys. This ensures they maintain their strength and longevity despite exposure to harsh marine conditions. For instance, ships like the Royal Caribbean’s Oasis Class rely heavily on bulb plates treated with corrosion-resistant coatings to extend the lifespan of their hulls. In addition to bulb plates, angle bars are commonly used in structural engineering. Learn how their sizes and materials impact their use in various projects. Bulb plates and angle bars are often used together in demanding construction tasks, ensuring the structure’s stability and strength.

3. Versatility

Bulb plates are available in various sizes and thicknesses, making them suitable for a wide range of applications. Whether used in the construction of maritime vessels, offshore platforms, or industrial structures, bulb plates can be tailored to meet specific design and performance requirements.

If you’re exploring materials for your next project, you should also take a look at expanded metal. Its versatility and strength make it another option worth considering alongside bulb plates for applications requiring high durability and flexibility.

Bulb Plate Applications

Bulb plates are used in various industries due to their superior strength and versatility. Below are some of the most common bulb plate applications:

1. Shipbuilding

In shipbuilding, bulb plates are essential for the construction of a ship’s hull. The plates provide the necessary strength to withstand the forces of water pressure and contribute to the overall stability of the vessel. The use of bulb plates in ship hulls is crucial for ensuring the vessel’s safety and durability during its lifetime.

For example, in the construction of container ships, bulb plates are used in the bow area to reduce drag and improve fuel efficiency. The large-scale vessels in the global shipping industry, like those owned by Maersk, incorporate bulb plates to maintain structural integrity while optimizing fuel usage.

2. Bridge Construction

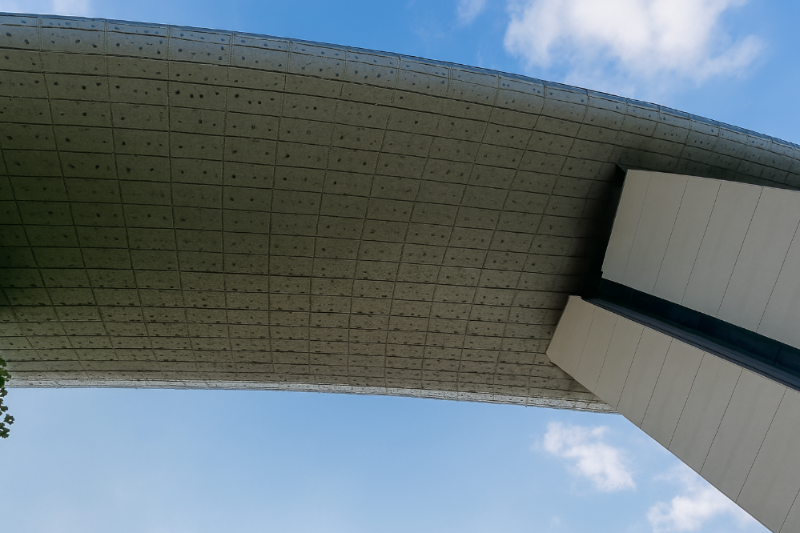

Bulb plates are also utilized in bridge construction. Their strength and flexibility make them an ideal choice for load-bearing elements in large infrastructure projects. In Singapore, for instance, bulb plates are employed in the construction of some of the city’s most iconic bridges, where they help support heavy traffic loads while maintaining the structure’s resilience.

3. Offshore Structures

Bulb plates are used in the construction of offshore oil rigs and platforms. Their ability to withstand harsh conditions, including constant exposure to saltwater, makes them ideal for ensuring the stability and safety of offshore installations. An example is the use of bulb plates in the construction of offshore drilling platforms in the South China Sea.

In Singapore, bulb plates are used in the construction of Marina Bay Sands, where they help maintain the structural integrity of the building’s steel framework. The versatility of bulb plates makes them ideal for projects requiring both strength and flexibility.

Advantages of Bulb Plates

The use of bulb plates offers numerous advantages in both marine and structural engineering applications. Some of the key benefits include:

1. Enhanced Structural Integrity

The unique shape of bulb plates allows for better distribution of stress, which results in increased structural integrity. This is particularly important in shipbuilding, where the hull must endure extreme pressures during its operational life. Bulb plates provide a durable and reliable solution for maintaining the vessel’s strength over time.

2. Weight Efficiency

Bulb plates are lighter compared to traditional steel plates of the same thickness, which makes them an excellent choice for applications where weight is a concern. In shipbuilding, for instance, the use of bulb plates helps reduce the overall weight of the vessel, contributing to improved fuel efficiency and lower operational costs.

3. Cost-Effective

While bulb plates may be slightly more expensive than traditional flat plates, they offer long-term cost savings due to their durability and reduced maintenance requirements. The use of bulb plates in large-scale infrastructure projects helps avoid the costs associated with frequent repairs or replacements.

4. Improved Hydrodynamics

In shipbuilding, bulb plates play a significant role in improving the hydrodynamics of a vessel. The unique shape helps reduce drag and increase the speed and efficiency of the ship. This is especially beneficial for modern commercial ships, which require optimized fuel consumption for profitability.

when planning structural designs, don’t forget to explore the uses of mild steel C-channels. Like bulb plates, mild steel C-channels offer excellent strength and flexibility, making them ideal for both shipbuilding and infrastructure projects.

Conclusion

At The Monster Builder, we recognize the critical role bulb plates play in sheet metal fabrication, especially in industries like shipbuilding, structural engineering, and large-scale infrastructure projects. With their unique design and robust properties, bulb plates enhance the strength, durability, and efficiency of fabricated structures, making them indispensable for high-demand applications.

By incorporating advanced sheet metal fabrication techniques, The Monster Builder ensures that each bulb plate meets the highest standards of quality and precision. Our expertise in customizing these plates for specific needs whether it’s for maritime vessels, bridges, or offshore structures allows us to deliver solutions that not only meet but exceed industry expectations.

When it comes to sheet metal fabrication, The Monster Builder continues to lead with cutting-edge technology and a commitment to quality, ensuring that every bulb plate we produce plays a vital role in shaping resilient and efficient structures worldwide.

For a deeper understanding of materials used in fabrication, we recommend reading about 3 main types of carbon steel. Knowing how these materials compare to the properties of bulb plates will help you select the best materials for your specific needs.