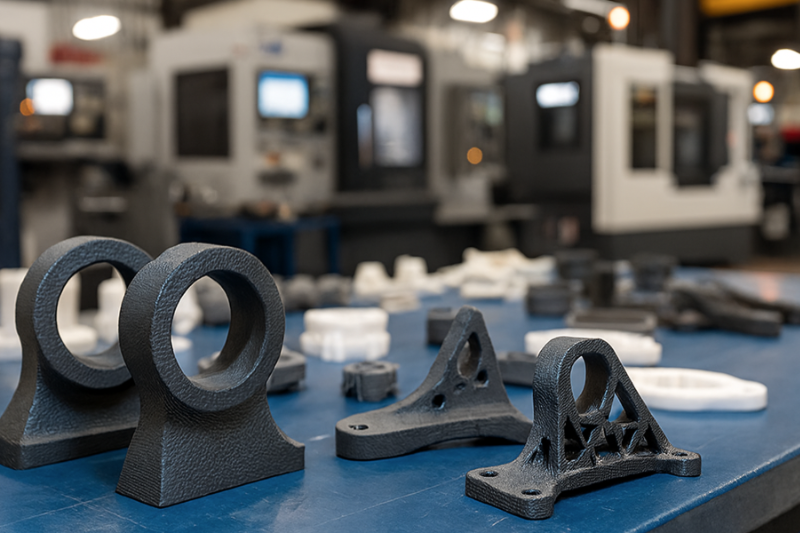

Are 3D Printed Parts Strong?

3D-printed parts can be strong enough for real-world use when you pair the right material with sound design, tuned print settings, and proper post-processing. This guide focuses on Singapore use cases, hot, humid workshops, fast prototyping cycles, and end-use parts for electronics, automation, and lab fixtures.

Are 3D Printed Parts Strong for Everyday Use?

Yes. 3D-printed parts can be strong enough for real-world use when you match material choice, design and print settings, and post-processing to the job. With the right polymer (e.g., nylon-based powders or engineering resins), good layer orientation, reinforced fastener zones, and proper curing/conditioning, printed parts rival many common engineering plastics.

In hot, humid environments like Singapore workshops, you also plan for moisture uptake and service temperature. With the right approach, printed polymers can rival many common engineering plastics used on the shop floor.

Material Choice

Choose materials based on load, temperature, and humidity:

- PA12 (nylon, powder-bed): Balanced strength and ductility, stable dimensions, good for clips, housings, and brackets. It tolerates Singapore’s humidity better than many entry-level filaments.

- Engineering resins (SLA): Stiff and precise for jigs, fixtures, and snap-fits that need smooth surfaces. Always fully post-cure to reach published properties.

- Reinforced polymers (FFF composites): Nylon mixed with chopped carbon or glass improves stiffness; continuous-fiber reinforcement (when available) can deliver aluminium-like rigidity at lower weight for jigs or robot grippers.

PA12 for tough functional parts, SLA for stiff & precise fixtures, composites for lightweight rigidity.

Design and Print Settings

- Orient for load paths. Place layer lines parallel to the main load whenever possible to reduce delamination risk. See how process choice affects anisotropy in our FDM vs SLA 3D Printing Comparison.

- Use thicker walls and more perimeters before you crank infill. Extra shells around holes and bosses do more for strength than a high infill percentage alone. Choose wall settings based on the base polymer in our guide to 3d printing materials, types and applications.

- Add fillets and ribs at stress hot-spots. Sharp corners concentrate stress; fillets spread it. This is fundamental across all additive processes. You can see how 3d printing relates to the broader field in 3d printing vs additive manufacturing.

- Respect process limits. Powder-bed parts tend to be more isotropic than basic FFF. SLA needs uniform wall sections to avoid weak zones.

- Fasteners & inserts. For repeat loads and assemblies, use heat-set inserts, through-bolts, or captive nuts to move peak stress into metal hardware.

Post-Processing

- SLA post-cure. UV and thermal post-cure are essential to reach the resin’s “datasheet” strength and stiffness. For resin process nuances, see LCD vs DLP vs SLA.

- Condition powder-bed parts. Follow vendor guidance to stabilise dimensions and properties before load.

- Surface finishing for durability. Media tumbling or dyeing won’t magically “strengthen” a weak design, but it can reduce micro-notches and improve handling wear.

- Stress-proof fastener zones. Add washers, crush sleeves, or bushings where screws clamp plastic.

Use Cases

EMS Jig for Driver Torque

Setup: PA12, 2.5–3.0 mm walls, 4+ perimeters around screw bosses, 35–45% infill, generous fillets, heat-set inserts.

Why it works: Ductile material + reinforced boss geometry handles repeated screwdriver torque on a non-air-conditioned line.

Robot End-Effector for Pick-and-Place

Setup: Carbon-filled nylon body with continuous fiber routed around bolt paths and along arms; through-bolts with washers.

Why it works: Directional reinforcement delivers high stiffness-to-weight, speeding cycles without bending or creep.

Metrology Fixture (Lab Contact Points)

Setup: Engineering SLA resin, fully post-cured, uniform wall thickness, lightly lapped contact faces.

Why it works: High stiffness and smooth surfaces produce repeatable measurements. Keep away from heat sources >60 °C.

Quality Assurance

- Print test coupons in the same orientation and settings as production parts.

- Do quick clamp or torque tests on sacrificial prints to confirm insert pull-out, hinge life, or snap-fit durability.

- Track batches. Document printer, material lot, build orientation, and post-processing so QA can trace issues.

- Cost–Strength Trade-Offs (Spend Where It Matters)

- Increase perimeters/walls and add local ribs before using very high infill.

- Use hybrid fasteners (plastic body, metal load path) to hit strength targets without overbuilding.

- Reserve continuous-fiber only for arms, bridges, and bolt paths that truly need it.

Need to budget test iterations? See typical factors in how much does it cost to 3d print a figure for a baseline on cost drivers.

Common Mistakes to Avoid

- Relying on infill alone for strength

- Ignoring layer orientation relative to load

- Skipping SLA post-cure or insert reinforcement

- Using sharp internal corners instead of fillets

- Storing hygroscopic materials open in humid rooms

Can 3D-printed parts replace metal?

For many jigs, fixtures, guards, and brackets—yes. Use composite polymers with local metal hardware for the load path. For high-temperature or high-impact jobs, consider metal or redesign the load path.

Conclusion

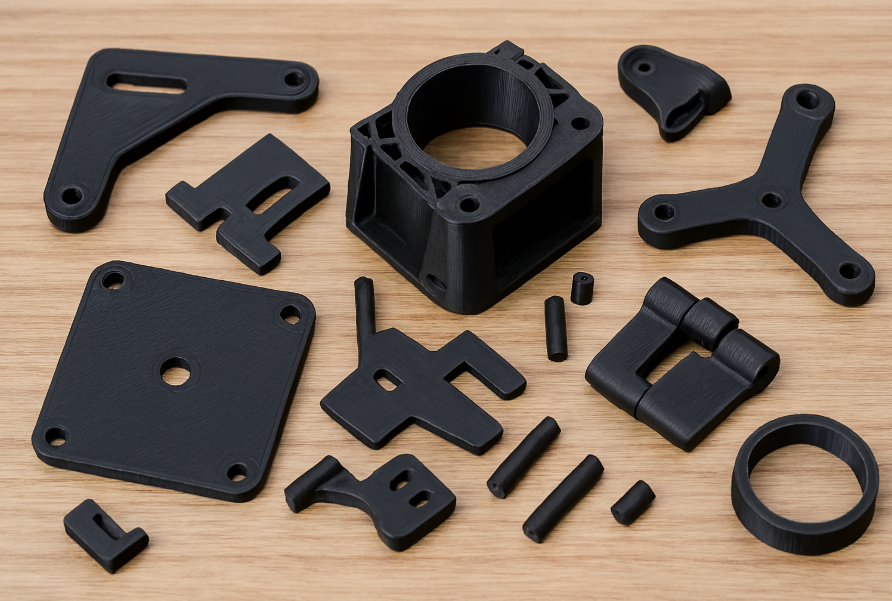

So, are 3D printed parts strong? Yes, when you match the material, process, and design to the job. Modern 3D printing delivers functional components that stand up to real use, from tough jigs to end-use housings. SLA 3D printing excels when you need crisp detail, tight tolerances, and engineering resins that balance stiffness with impact resistance. FDM 3D printing is a great choice for fast, practical parts with solid layer adhesion and reliable strength for everyday fixtures and prototypes.

If you want the best result, design for the process, choose the right resin or filament, and validate with simple stress tests. Partnering with The Monster Builder gives you access to material guidance, print tuning, and quality checks so your parts are not just printable but durable in the real world.