Can Galvanised Steel be Powder Coated?

Yes, galvanised steel can be powder coated, and when done correctly, it offers superior corrosion resistance, longer durability, and a more attractive finish. For outdoor Singapore environments, high humidity, marine exposure, frequent rainfall, combining galvanising and powder coating provides one of the strongest protection systems available for steel structures.

Galvanised steel can be powder coated, but it must be prepared carefully. The zinc layer sometimes releases trapped moisture or gases, which causes adhesion failure or bubbling if the coating is applied without proper preparation.

Professional metal fabricators in Singapore often use hot-dip galvanising plus powder coating (Duplex Coating System). This provides double protection: zinc for corrosion resistance and powder coating for aesthetics and additional weather protection.

What Is Galvanised Steel?

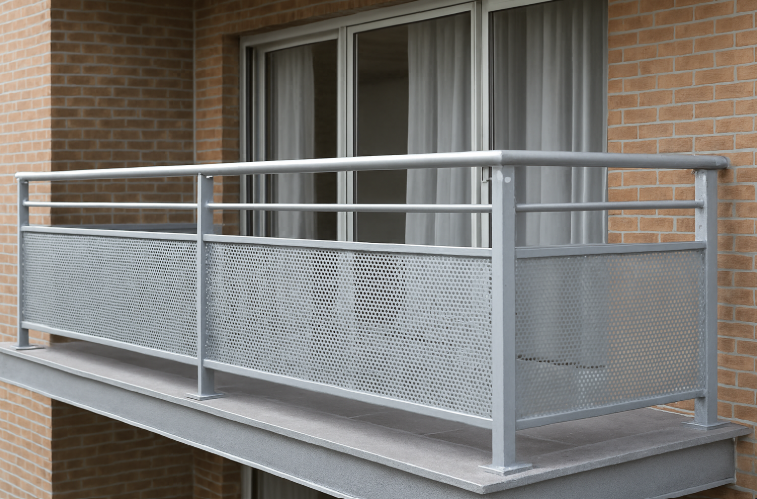

Galvanised steel has a protective zinc coating that prevents rust. In Singapore’s humid, coastal environment, galvanised steel is widely used for HDB corridor gates, Outdoor staircases, Building structures, Fencing and railings and Industrial platforms. But while galvanising protects the metal, many customers still want a smooth, coloured finish, this is where powder coating comes in.

Galvanised metal is often used for mesh and grating, for instance, many contractors choose expanded metal mesh for secure fencing or architectural panels.

Why Powder Coat Galvanised Steel?

Powder coating adds benefits that galvanising alone cannot provide.

Better Appearance

Galvanised steel has a silver, spangled surface. Powder coating creates a smooth, uniform colour (e.g., black, white, gold, textured, matte). Many Singapore landed house gates use galvanised steel but rely on powder coating for a premium, modern look.

Extra Corrosion Protection

The duplex system (zinc + powder coat) can increase durability by up to 1.5–2x compared to galvanising alone.

Longer Lifespan in Singapore’s Climate

Humidity, UV exposure, and coastal air accelerate corrosion. Powder coating offers a barrier that protects the zinc layer underneath.

Low Maintenance

Powder-coated galvanised steel doesn’t peel easily and requires minimal maintenance beyond simple cleaning.

For example, a galvanised staircase frame installed at a Singapore industrial facility was further powder-coated. After 8+ years outdoors, the structure shows minimal wear, while uncoated galvanised steel nearby shows chalking and oxidation.

For uses where tubular support or framing is needed such as railings or support frames. Many builders choose galvanised pipes.

How to Prep Galvanized Steel for Powder Coating

Proper surface preparation is essential for the coating to adhere correctly.

Step 1: Degreasing

Remove oil, dirt, and contaminants using an alkaline cleaner or solvent.

Step 2: Surface Profiling (Keying the Surface)

Galvanised steel must be slightly roughened to help the powder stick. Techniques include sweep blasting (light abrasive blasting), chemical etching and hand sanding for smaller items

Step 3: Outgassing (Pre-bake)

Because zinc can trap moisture, the metal is pre-heated to release trapped gases before coating.

Step 4: Apply Powder Coat & Cure

The powder coating is applied electrostatically and baked at high temperature to form a hard, durable finish.

Powder Coating vs Galvanising: What’s the Difference?

Galvanising protects steel by applying a zinc layer that prevents rust from forming, while powder coating adds a durable, coloured finish that improves appearance and adds extra UV and weather resistance. Galvanising is best for corrosion protection, especially in outdoor environments, while powder coating is ideal for achieving a smooth, aesthetic finish. For maximum durability, both methods can be combined, galvanised steel followed by powder coating, known as a duplex coating system.

Both coatings protect metal but work differently.

Powder Coating

- Heat-cured coloured finish

- Smooth, decorative appearance

- Great UV and weather resistance

- Ideal for gates, furniture, railings

Galvanising

- Zinc coating prevents rust

- Rougher look

- Best for structural items exposed long-term

- Ideal for industrial or construction use

Using Both Together

Many fabricators combine them for maximum protection, especially for condo balcony railings, exterior building frames, HDB gate upgrades, outdoor metal furniture. This is the most recommended solution for Singapore’s weather.

What Metals Cannot Be Powder Coated?

Powder coating needs a surface that can withstand high curing temperatures (typically 160–200°C).

Metals NOT recommended for powder coating include:

- Low-melting-point metals like lead or tin

- Alloys with high heat sensitivity

- Zinc-rich die castings (may outgas heavily unless pre-treated)

Metals that can be powder coated include:

- Galvanised steel

- Mild steel

- Aluminium

- Stainless steel (with correct preparation)

What Is the Best Coating for Galvanized Steel?

For outdoor use in Singapore, the Duplex Coating System like Galvanising plus Powder Coating is widely considered the best overall finish because it provides superior corrosion resistance, long-term durability, customizable colours, UV-resistant protection and premium visual appeal. This is the best coating way that is commonly used for building and home improvement projects across Singapore.

A property developer in Singapore installed steel balcony railings originally only galvanised. After 5–6 years, oxidation stains began appearing. On later projects, they applied duplex coating (galvanising plus powder coating). This results zero rusting after 7+ years, better visual appeal, less repainting required, and higher long-term value. This demonstrates real performance difference in Singapore’s weather conditions.

Why Choose The Monster Builder?

At The Monster Builder, we focus on precision metal fabrication and finishing quality. We offer industrial-grade powder coating, correct surface prep for galvanised steel, guidance on material selection, experience with Singapore building standards and long-term durability solutions.

Whether you’re building railings, gates, machinery housings, or architectural structures, our expertise ensures the coating lasts. Contact us today.