Galvanising Explained: Everything You Need to Know

Steel is one of the most widely used materials in construction and manufacturing, but it is vulnerable to rust when exposed to moisture. In Singapore’s hot and humid climate, this challenge is even greater. That is why many industries rely on galvanised steel, a solution that protects against corrosion and extends the lifespan of vital structures.

In construction, galvanised steel is frequently used to protect mild steel C-channels and custom lip channels. These structural components benefit from galvanising because it increases their strength and extends their lifespan in Singapore’s humid environment.

What is Galvanising?

Galvanising is the process of coating steel or iron with a protective layer of zinc to prevent rust and corrosion. The zinc forms a barrier against moisture and provides cathodic protection, meaning it sacrifices itself to protect the metal underneath. This makes galvanised steel durable and long-lasting, even in humid environments.

In Singapore, galvanised products are commonly seen in construction projects, marine equipment, and everyday structures such as fences, railings, and roofing sheets.

How Does Galvanising Work?

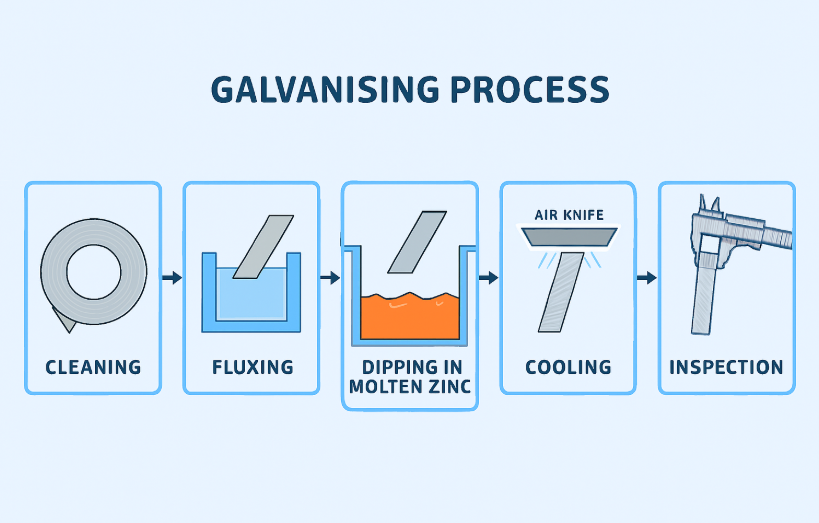

The most popular technique is hot-dip galvanising. In this process, steel is cleaned, prepared, and then dipped into molten zinc at about 450°C. As the steel emerges, the zinc reacts with its surface to form a strong, metallurgical bond. This bond does more than just coat the steel. It creates multiple protective layers.

What makes galvanised steel special is its self-sacrificing protection. If the coating is scratched or damaged, the zinc corrodes first, preventing rust from spreading to the steel underneath. This is known as cathodic protection, and it ensures long-term durability even in challenging environments.

For example, galvanised steel handrails installed in public housing projects across Singapore withstand daily use and tropical rain without frequent replacement or repairs.

When comparing materials, it is important to note that stainless steel offers unique properties. For example stainless steel 304 vs 316 is a common consideration for businesses that need higher-grade corrosion resistance, especially in marine or chemical industries.

Types of Galvanising

Galvanising is not a one-size-fits-all process. Different methods create different coating thickness, durability, and cost levels. Here are the four main types of galvanising and how they are applied in practice:

Hot-Dip Galvanising

Steel is dipped into molten zinc at around 450°C, forming a metallurgical bond that creates multiple protective layers. Hot-dip galvanising is known for its durability and ability to last decades, even in harsh conditions. In Singapore, it is often used for bridges, building beams, and public infrastructure such as railings and lamp posts. These structures face heavy rainfall and high humidity, yet the galvanised coating ensures long service life with minimal maintenance.

Hot-Dip Galvanising is the most widely used method in Singapore because of its durability in outdoor conditions. It is often applied to structural beams, railings, and even galvanised pipes in Singapore, they are trusted for plumbing and construction projects due to their long-lasting protection.

Electro-Galvanising

An electric current is used to coat steel with a thin, uniform layer of zinc. Unlike hot-dip galvanising, this process produces a thinner, more uniform coating with a smooth finish. It is especially useful for components that require a neat appearance or will be painted afterwards. Common applications include automotive body panels, household appliances, and electronic parts. For example, Singapore’s automotive manufacturing sector often relies on electro-galvanised sheets because they combine corrosion resistance with lightweight efficiency.

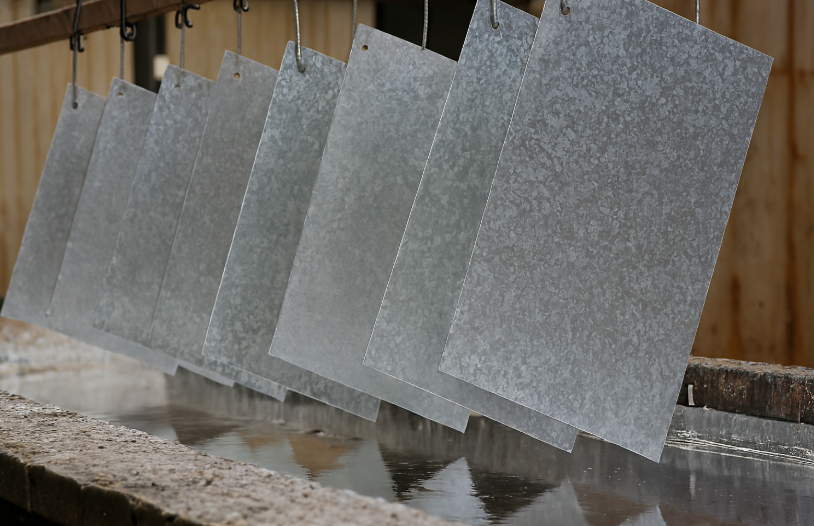

Pre-Galvanising

teel coils or sheets are galvanised at the mill before fabrication. After cutting and welding, exposed edges may need extra coating. This approach is efficient for mass production, but cutting and welding after the process may leave edges exposed, requiring touch-ups. Despite this limitation, pre-galvanised steel is popular in Singapore’s construction sector for cable trays, ducts, roofing sheets, and pipelines. A familiar example is the use of pre-galvanised cable trays in commercial office towers, where they protect electrical wiring from moisture damage.

Mechanical Galvanising

Zinc powder and media are tumbled with steel parts, creating a bonded protective layer. Mechanical galvanising is particularly suitable for bolts, nuts, and screws, as it avoids the risk of hydrogen embrittlement that can occur in electro processes. In Singapore’s HDB housing projects, construction bolts are frequently mechanically galvanised to ensure they remain strong and rust-resistant over time.

Together, these four methods such as hot-dip, electro, pre-galvanising, and mechanical offer a range of solutions that balance durability, cost, and efficiency. By choosing the right type, businesses in Singapore can ensure their steel structures and components remain reliable in the country’s demanding tropical climate.

Advantages of Galvanised Steel

Choosing galvanised steel offers many benefits:

- Long-lasting performance – Depending on the environment, galvanised steel can last 20 to 50 years without major maintenance.

- Cost savings over time – Although the initial price is higher than untreated steel, reduced repairs and replacements make it cost-effective in the long run.

- Durability in Singapore’s climate – The zinc coating withstands constant humidity, making it ideal for coastal and tropical environments.

- Environmentally friendly – Zinc is recyclable, and galvanising helps reduce waste by extending the lifespan of steel products.

While galvanised steel is effective, some industries prefer alternatives such as stainless steel fabrication in Singapore, it offers excellent resistance and a more polished finish for architectural projects.

Disadvantages of Galvanised Steel

Despite its benefits, galvanising also has some drawbacks:

- Higher upfront cost – It is more expensive than painting or using untreated steel.

- Design limitations – Extremely thick or irregularly shaped steel parts may not be suitable for all galvanising methods.

- Repair challenges – Once damaged, galvanised coatings can be harder to patch compared to painted surfaces.

Conclusion

Galvanising is one of the most effective ways to protect steel against rust, corrosion, and the effects of Singapore’s tropical climate. Whether through hot-dip galvanising for large infrastructure, electro-galvanising for automotive and appliances, pre-galvanising for mass-produced steel sheets, or mechanical galvanising for fasteners, each method serves a specific purpose with proven advantages.

For businesses in Singapore, choosing the right galvanised solution ensures durability, cost savings, and long-term reliability. At The Monster Builder, we provide expert guidance and high-quality galvanised products tailored to local industry needs. With our knowledge and experience, you can trust us to deliver steel solutions that last, protecting your projects today and into the future.