How PLA Is Made: Sustainable 3D Printing Material

How PLA is made matters more than ever as industries shift toward sustainable materials. PLA (Polylactic Acid) is a plant-derived bio-plastic used extensively in 3D printing, packaging, and injection molding. By understanding its production process, engineers, designers and procurement teams can make smarter material choices.

What Is PLA (Polylactic Acid)?

PLA is a bio-based thermoplastic polymer made primarily from fermented plant starch such as corn, sugarcane or cassava. While PLA is classified as a plastic, it originates from renewable resources rather than petroleum.

Key properties:

- Derived from plant sugars

- Melting point around 150–160 °C; printing temp 180–220 °C

- Glass transition temperature ~55–65 °C

- Compostable under industrial conditions

- Compatible with FDM 3D Printing

How PLA Is Made Step by Step

Source & prep plant sugars

Manufacturers mill corn, sugarcane, sugar beet, or cassava to obtain starch/sucrose. They liquefy and enzymatically hydrolyze the starch to glucose, creating a clean sugar stream ready for fermentation.

Ferment sugars to lactic acid

Microorganisms consume the sugars and produce lactic acid. Operators control temperature, pH, and residence time to hit target yield and optical purity (L- or D-lactic acid), which later affects PLA crystallinity and properties. The broth then gets filtered and purified to high-purity lactic acid.

Make lactide (the cyclic dimer)

Chemists dehydrate and dimerize lactic acid to lactide. You get three stereochemical forms: L-lactide, D-lactide, and meso-lactide. Controlling this mix is critical because it drives clarity, stiffness, and heat resistance in the final PLA.

Polymerize via ring-opening

Processors feed lactide into a ring-opening polymerization reactor with carefully chosen catalysts and tight moisture control to build high-molecular-weight PLA. They fine-tune molecular weight distribution for printability, toughness, and flow.

Purify, pelletize & compound

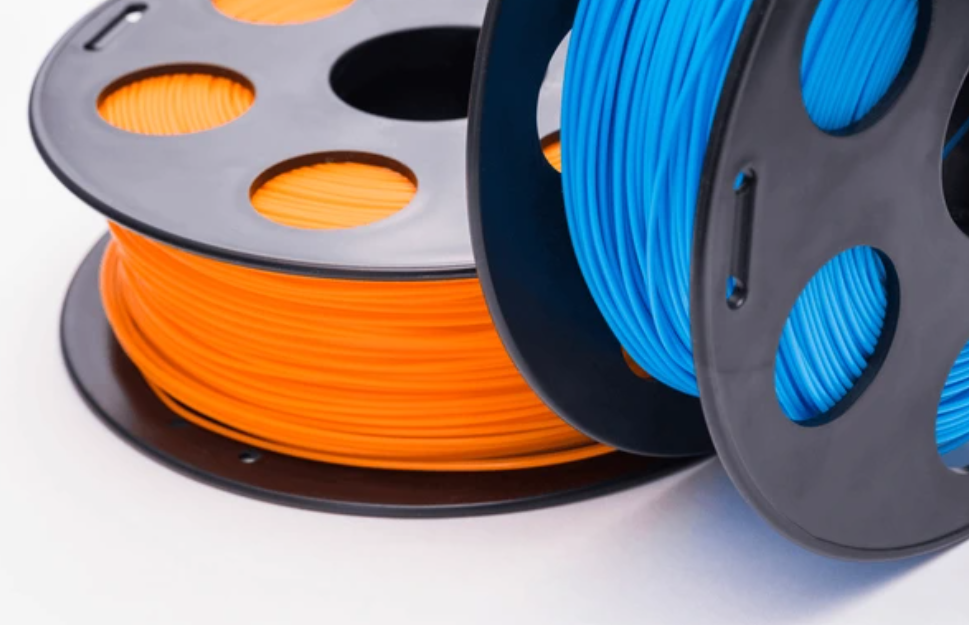

The hot melt gets purified, then cut into pellets. Compounders add colorants, nucleating agents, stabilizers, or impact modifiers to tailor behavior (e.g., easier printing, higher heat resistance, better clarity). Drying steps prevent hydrolysis during processing.

Convert pellets into parts

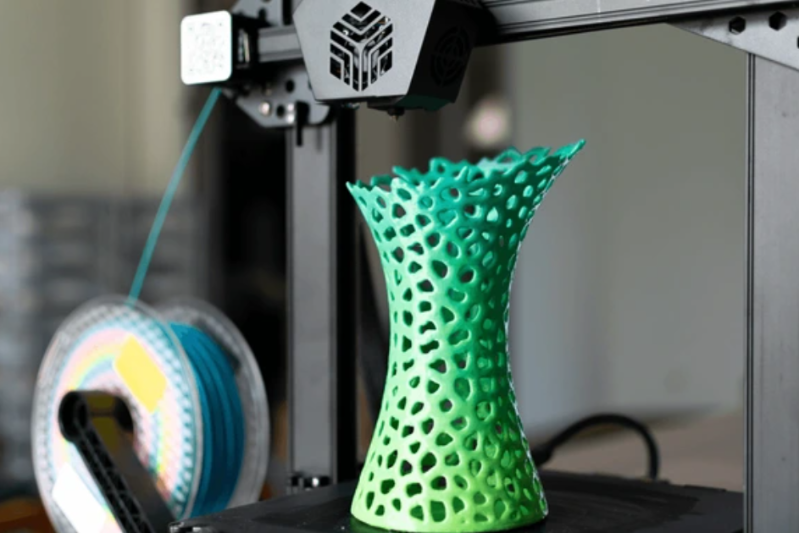

- Filament extrusion (for FDM): Extruders draw 1.75/2.85 mm PLA filament with tight diameter control for smooth printing (typical print temps ~180–220 °C).

- Sheet/film extrusion & thermoforming: Lines make packaging film, trays, blister packs.

- Injection molding: Molders run PLA pellets into end-use components under optimized temperatures and residence times.

Is PLA Actually Plastic?

Yes. PLA is a bio-plastic that made from plant-derived raw materials rather than fossil fuels. It behaves like conventional plastic in many applications but has a lower carbon footprint.

How to Identify Products Made from PLA

- Look for PLA markings or certification logos.

- Check the melting and printing temperatures. PLA typically extrudes at 180–220 °C.

- PLA parts feel smoother and less brittle than many other bioplastics.

For projects needing exact replicas of PLA components, 3d scanning and reverse engineering plus cnc machining can reproduce parts precisely.

PLA vs ABS

PLA is easier to print, plant-based, and lower-temperature. ABS is petroleum-based, tougher at high heat but warps more easily.

- Material Origin: PLA is a plant-based bio-plastic from renewable resources such as corn starch or sugarcane; ABS is a petroleum-based thermoplastic derived from fossil fuels.

- Printing Temperature: PLA prints at lower temperatures (around 180–220 °C) and often doesn’t require a heated bed; ABS prints hotter (around 220–250 °C) and usually needs a heated bed and enclosed chamber to prevent warping.

- Warping and Odor: PLA has minimal warping and emits very little odor during printing, making it safer for offices, labs and classrooms; ABS can warp more easily and releases a stronger smell.

- Surface Finish: PLA provides a smooth, glossy surface ideal for prototypes, architectural models, and educational projects; ABS offers a matte finish and can be post-processed with acetone vapor for a smooth, sealed surface.

- Mechanical Properties: PLA is moderately strong and stiff, but not as impact-resistant or heat-resistant as ABS; ABS handles higher temperatures (glass transition ~105 °C) and offers better impact resistance for functional parts.

- Environmental Profile: PLA is industrially compostable and comes from renewable resources, appealing to sustainability-focused users; ABS is non-compostable and fully fossil-based.

- Best Uses: Choose PLA for eco-friendly, fast, low-warp prints; choose ABS for durable, high-temperature, or impact-resistant parts.

PLA and ABS are two of the most common 3d printing materials used in FDM printing.

FDM excels at fast, cost-effective prototypes. For ultra-fine layers and intricate details, SLA 3D Printing offers higher resolution. See our FDM vs SLA 3D Printing comparison to decide which works best for your project.

Is PLA 100% Plant-Based?

PLA is largely plant-based but not 100%. The feedstock is renewable plant sugars; however, the polymerization process uses chemical catalysts and may include additives. It’s accurate to say PLA is “bio-based” or “plant-derived” rather than “100% plant.”

Is PLA Easy to Produce?

PLA production is straightforward in terms of feedstock but requires sophisticated equipment to achieve consistent quality and high molecular weight. Compared to petroleum plastics, PLA production reduces reliance on fossil resources but still demands precise process control.

PLA in 3D Printing and Fabrication

PLA is the most widely used filament in FDM 3D Printing and an increasingly viable material for plastic injection molding prototypes. Its low warping, dimensional accuracy and plant-derived origins make it ideal for engineers, designers and educators.

Examples of PLA Applications

- Rapid Prototypes for Consumer Products: casings, housings, fixtures, jigs.

- Architectural Models: building facades, interiors, detailed scale models.

- Medical/Dental Models: anatomical study models, surgical guides.

- Educational Projects: robotics parts, teaching aids, and STEM projects.

- Packaging Mockups: trays, inserts, and point-of-sale prototypes.

- Tooling & Assembly Aids: alignment jigs, test fixtures, non-marring assembly tools.

Advantages of Using PLA in 3D Printing

- Ease of Printing: PLA prints at low temperatures (~180–220 °C) and rarely requires a heated chamber.

- Smooth Surface Finish: Ideal for display models, consumer prototypes, and low-friction parts.

- Low Odor and Minimal Warping: Safer and more reliable in office or lab environments.

- Eco-Friendly Appeal: Bio-based origin attracts sustainability-conscious clients.

- Versatile Post-Processing: Parts can be sanded, primed, painted, bonded or machined for finishing touches.

For high-detail showpieces or production masters, print in PLA using FDM for bulk and SLA for fine detail, then combine with aluminium sheet fabrication or steel fabrication for hybrid assemblies.

Conclusion

Learning how PLA is made, along with its strengths and limitations compared to ABS, gives designers and engineers a clearer picture of which material best fits their needs. PLA offers an easy-to-print, plant-derived option for sustainable prototypes, while ABS provides higher impact and heat resistance for more demanding applications.

Drawing on practical experience across 3D printing, CNC machining, and injection molding, The Monster Builder shares these insights to help you plan, prototype and produce with confidence. By understanding the full material lifecycle, you can make better choices that balance performance, cost, and sustainability for every project.