How to Bond Acrylic to Metal

Bonding acrylic to metal may sound simple, but it demands precision and the right materials. Whether you are building acrylic signboards, display fixtures, or industrial parts, the success of your project depends on understanding how to bond acrylic to metal properly. With the right adhesive and surface preparation, you can achieve a bond that’s both durable and visually clean. It is ideal for Singapore’s humid and high-temperature environment.

Challenge of Acrylic-to-Metal Bonding

Acrylic (also known as PMMA) is smooth, lightweight, and transparent. Metals such as aluminium, stainless steel, or brass are dense and rigid. Because of their different surface properties, these two materials do not naturally bond well. If you use the wrong adhesive or skip surface preparation, the bond may weaken over time, leading to cracks, delamination, or yellowing.

Singapore’s weather makes this challenge greater. High humidity and fluctuating indoor temperatures can cause thermal expansion, putting extra stress on bonded joints. That’s why choosing the right acrylic-to-metal adhesive and applying it correctly are essential.

Steps on How to Bond Acrylic to Metal

Step 1: Clean and Prepare the Surfaces

Before you apply any adhesive, both materials must be completely clean. Dust, grease, or fingerprints can prevent the adhesive from sticking.

- For metal: Wipe the surface with isopropyl alcohol or acetone to remove oil and oxidation. Lightly sand the metal using fine-grit sandpaper (around 180–320 grit) to increase surface area for better adhesion.

- For acrylic: Use mild soap and warm water to clean, then dry it with a lint-free cloth. Avoid using harsh solvents that can damage the surface.

Proper surface preparation works similarly to how finishes are handled in painting over anodized aluminium where surface texture directly affects coating and bonding strength.

Step 2: Choose the Right Adhesive

The adhesive you choose determines how strong and long-lasting your bond will be. Here are the most effective options:

Methyl Methacrylate (MMA) Adhesives

MMA adhesives are one of the best choices for bonding acrylic to metal. They cure quickly, provide high shear strength, and resist impact and temperature changes, perfect for signboards and structural fixtures.

Epoxy Adhesives

Two-part epoxy adhesives are another reliable option. They provide excellent bonding for smaller or precision assemblies, such as metal brackets or lighting fixtures attached to acrylic panels.

UV-Curing Adhesives

For clear acrylic projects where appearance matters, UV-curing adhesives offer invisible bonds. They work best when at least one material (like acrylic) allows UV light to pass through during curing. Many fabricators in Singapore use two-part MMA adhesives for acrylic-metal signage because they maintain strength even under the island’s high humidity and daily temperature shifts.

When selecting adhesives for metal components, understanding how different machining methods affect surface texture such as in laser cutting vs CNC milling

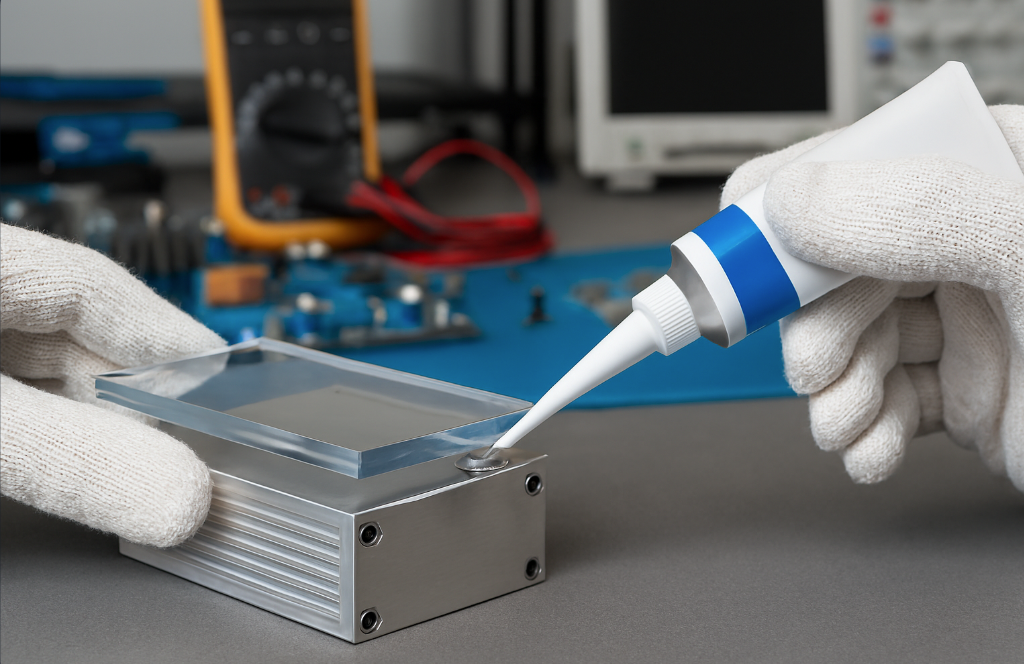

Step 3: Apply the Adhesive Evenly

Spread a thin, uniform layer of adhesive on the metal surface. Too much adhesive can trap air bubbles and cause weak points. Align the acrylic piece carefully before the adhesive starts to cure.

Step 4: Clamp and Cure the Bond

Use clamps, jigs, or weights to hold the acrylic and metal in place while the adhesive cures. The curing time depends on the adhesive type:

- MMA adhesives: typically 10–20 minutes to handle strength

- Epoxy adhesives: may take 4–24 hours to fully cure

- UV adhesives: cure instantly under UV light

Step 5: Test and Finish the Bond

Once the adhesive has cured, check the bond’s strength by applying gentle pressure or flexing the joint slightly. If it holds without gaps or movement, your acrylic-to-metal bond is ready for long-term use.

For aesthetic projects, you can polish the edges of acrylic after bonding to achieve a clear, professional finish.

Common Mistakes to Avoid

When bonding acrylic to metal, even small errors can weaken the joint or ruin the finish. Below are the most common mistakes to avoid:

- Skipping Surface Preparation – Dirt, oil, or oxidation can prevent proper adhesion. Always clean and lightly sand both surfaces first.

- Using the Wrong Adhesive – General glues or silicone sealants won’t last. Use structural adhesives like MMA, epoxy, or UV-curing formulas.

- Applying Too Much Adhesive – Excess glue can trap air bubbles and create weak spots or visible residue.

- Over-Clamping – Tight clamping squeezes out adhesive and reduces bond strength. Moderate, even pressure works best.

- Ignoring Curing Times – Handling too soon can break the bond. Always follow the manufacturer’s recommended curing schedule.

- Poor Environmental Control – High humidity or dust can affect bonding. Work in a clean, dry, well-ventilated area.

By avoiding these mistakes, you ensure a strong, clear, and lasting bond between acrylic and metal suitable for Singapore’s humid conditions.

Real Examples

Retail Display Fabrication

In Singapore’s retail sector, acrylic signage and aluminium frames are common in malls such as ION Orchard and VivoCity.

Fabricators often use two-part MMA adhesives to bond laser-cut acrylic letters onto brushed aluminium backplates. This adhesive offers high impact resistance and remains stable under air-conditioned indoor lighting, where temperature changes can cause stress on the joint.

Architectural Installations

Architects and builders use acrylic panels as decorative façades or partition features mounted on stainless steel brackets.

To ensure durability in Singapore’s humid climate, they use industrial-grade epoxy adhesives. Epoxies prevent corrosion, bond well to metal, and resist moisture, ideal for both indoor and semi-outdoor applications like building lobbies or balcony railings.

For decorative façades or support structures, mild steel C-channels are often paired with acrylic or glass panels, requiring strong adhesive bonds and precise alignment.

Electronics and Prototype Assembly

In electronics or robotics labs, engineers bond clear acrylic covers to aluminium housings for prototypes or testing equipment.

Because precision matters, UV-curing adhesives are preferred. They provide optical clarity, quick curing under UV light, and strong adhesion without adding extra thickness, making them perfect for delicate assemblies.

Final Tips for Perfect Acrylic-to-Metal Bonds

To bond acrylic to metal effectively, focus on preparation, precision, and patience. These quick tips help ensure a strong, clean, and lasting result:

- Store adhesives in a cool, dry place below 25°C.

- Test your chosen adhesive on a small sample before full assembly.

- When working with clear acrylic, choose UV-resistant or clear adhesives for the best visual outcome.

- Ensure ventilation while working with strong adhesives to prevent fumes.

Proper preparation and adhesive selection make all the difference between a temporary fix and a professional, lasting bond.

Expanded metal panels, like those described in our guide on expanded metal features, benefits and applications can also be bonded or framed using similar techniques for durable results.

Conclusion

Knowing how to bond acrylic to metal correctly makes a big difference in the strength and finish of your project. From signage and prototypes to industrial assemblies, success comes from clean surfaces, the right adhesive, and proper curing.

At The Monster Builder, we apply these same principles across our sheet metal fabrication and CNC machining services in Singapore. Our team understands material compatibility and precision engineering, ensuring every acrylic-to-metal assembly is durable, accurate, and visually refined.

Whether you need custom metal components, precision acrylic fittings, or complete fabricated structures, The Monster Builder delivers solutions that meet industrial standards and aesthetic expectations.

If your project involves precision cutting or drilling before bonding, our resources on drilling machine types and uses can help you prepare metal surfaces more efficiently.