How to Measure Chequered Plate Thickness

Chequered plates often called checker plates or tread plates, whether aluminium or stainless steel, they are widely used in Singapore for flooring, industrial walkways, car decks, loading ramps, and anti-slip applications.

Understanding how to measure chequered plate thickness correctly is essential for choosing the right material and ensuring structural safety. The correct measurement is always taken from the base metal only, not the raised diamond pattern.

What is the Thickness of a Chequered Plate?

The thickness of a chequered plate refers only to the flat base metal, not including the raised diamond pattern on the surface. For example, if a chequered plate is listed as 3mm, that 3mm represents the thickness of the smooth underside, while the patterned texture adds additional height (typically another 1–2mm) but is not counted as part of the structural thickness. This distinction is important because engineering calculations, load-bearing capacity, fabrication suitability, and safety standards are all based on the base thickness, not the total height including the bumps.

When a plate is listed as 2mm, 3mm, 4.5mm, 6mm, or 8mm, this refers only to the flat base thickness.

For example, a 3mm aluminium chequered plate may have ~1.5–2mm additional height from the pattern. So the total height might feel like ~5mm but the engineering thickness remains 3mm.

This matters for actual load capacity, flooring safety, fabrication requirements, weight calculations and cost and material efficiency.

If your projects require alternative anti-slip solutions, you may also consider bulb plates and their applications, especially for marine, ship decks, and load-bearing industrial platforms.

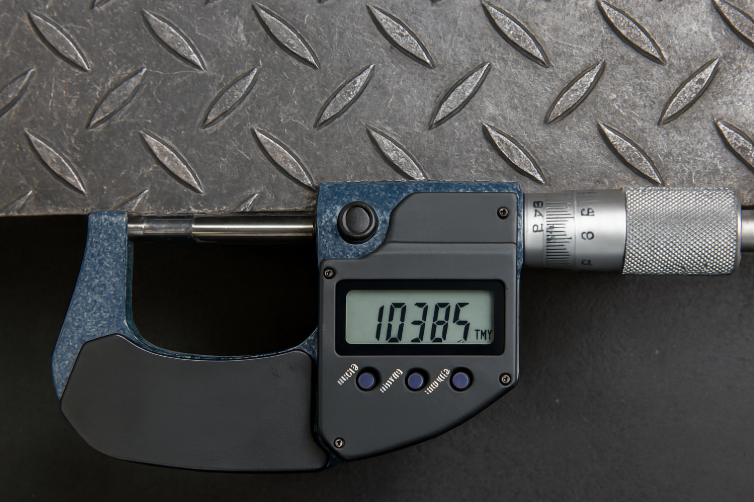

How to Measure Thickness

Many new engineers mistakenly measure total thickness including the bumps, this leads to wrong readings and can affect structural safety.

Correct measurement should always be taken on the underside of the plate, or on the flat region between the raised patterns.

To measure chequered plate thickness correctly, always measure only the flat base metal and not the raised diamond pattern. Use a caliper or micrometer to take the reading from the smooth underside or from a flat area between the patterns. This ensures you get the true structural thickness which is essential for load-bearing calculation, fabrication accuracy, and correct material selection for aluminium or stainless steel applications.

Because for fabrication, even a 0.5mm difference can affect welding specification, bending & forming, load distribution, visual alignment and bolt and bracket fitment.

What Thickness of Chequered Plate Is Available in Singapore?

Chequered plates commonly come in these base thicknesses like 2mm, 3mm, 4.5mm, 6mm and 8mm.

Example Application Guide:

- 2–3mm: toolboxes, decorative surfaces, protective cladding

- 4.5–6mm: flooring, walkway surfaces, stairs, warehouse applications

- 8mm and above: heavy-duty industrial and structural use

At The Monster Builder, we supply a range of chequered plate materials suitable for residential, commercial, automotive, and industrial needs across Singapore.

Recently, there is a facilities management team needed to upgrade a vehicle ramp surface. The initial measurement incorrectly recorded the plate as 5mm, using the raised pattern. After correct measurement, the actual base plate was 3mm. This changed the reinforcement requirement and ensured safer long-term performance.

Another example, a logistics company in Tuas ordered chequered plates for a loading ramp.

Their initial assumption 4mm thickness measured including pattern which is incorrect, the actual base thickness is actually 2.5mm. Our team re-measured and advised them to upgrade to 4.5mm base stainless steel, which ensured higher weight capacity, longer lifespan, better friction and zero structural risk. Correct measurement saved them from premature flooring failure and additional replacement cost.

If your project involves precision fabrication or custom cutting, our guide on sheet metal laser cutting prices and cost factors will help you estimate fabrication expenses accurately.

Aluminium vs Stainless Steel Chequered Plates

Aluminium chequered plates are lightweight, corrosion-resistant, and ideal for applications like vehicle flooring, toolboxes, and marine environments, where reduced weight and easier fabrication are important. Stainless steel chequered plates are heavier, stronger, and more durable, making them suitable for heavy-duty industrial walkways, structural platforms, and high-traffic areas where maximum strength and long-term wear resistance are required.

When to Choose Aluminium Chequered Plate

Aluminium chequered plates are light, corrosion-resistant, and easy to work with, making them ideal for areas where weight and weather durability are important. They are commonly used in applications such as vehicle flooring, marine environments, storage boxes, wall protection, ramps, and interior architecture. Because aluminium is easier to cut, bend, and fabricate, it is preferred for custom aluminium fabrication projects where flexibility, aesthetic finish, and reduced weight are key priorities.

When to Choose Stainless Steel Chequered Plate

Stainless steel chequered plates are significantly stronger, heavier, and more resistant to wear, impact, and heavy traffic than aluminium. They are chosen for industrial environments such as loading docks, heavy-duty walkways, machinery platforms, stair treads, and areas exposed to chemical or mechanical stress. Stainless steel offers higher structural rigidity and can withstand heavier loads, making it a more suitable option when safety, durability, and long-term performance are essential, particularly for industrial and commercial fabrication projects.

When comparing different metal flooring options, you can also explore the advantages of chequered plate vs plain steel plate to understand the best fit for your structural and commercial applications.

Why Work With The Monster Builder Fabrication Company

The Monster Builder is a Singapore-based metal fabrication specialist with a team of experienced engineers, welders, and technicians dedicated to delivering high-precision aluminium and stainless steel solutions. We combine technical expertise with real-world fabrication experience, ensuring every project is measured accurately, built to specification, and finished to professional industrial standards. Our team understands local project requirements, safety considerations, and Singapore-specific usage environments, which allows us to recommend the right materials, thicknesses, and fabrication methods for long-term durability and performance. Whether you need custom aluminium fabrication, stainless steel fabrication, or industrial chequered plate solutions, we deliver precision-built results that meet Singapore safety and engineering standards.

If you need help selecting the right plate thickness or material for your project like walkway, staircase, vehicle deck, warehouse flooring or structural application, we’re here to help. Send us your project requirements today and we’ll guide you to the best aluminium or stainless steel solution.