Is Aluminium a Metal? Alloys & Fabrication Singapore

Is Aluminium a Metal?

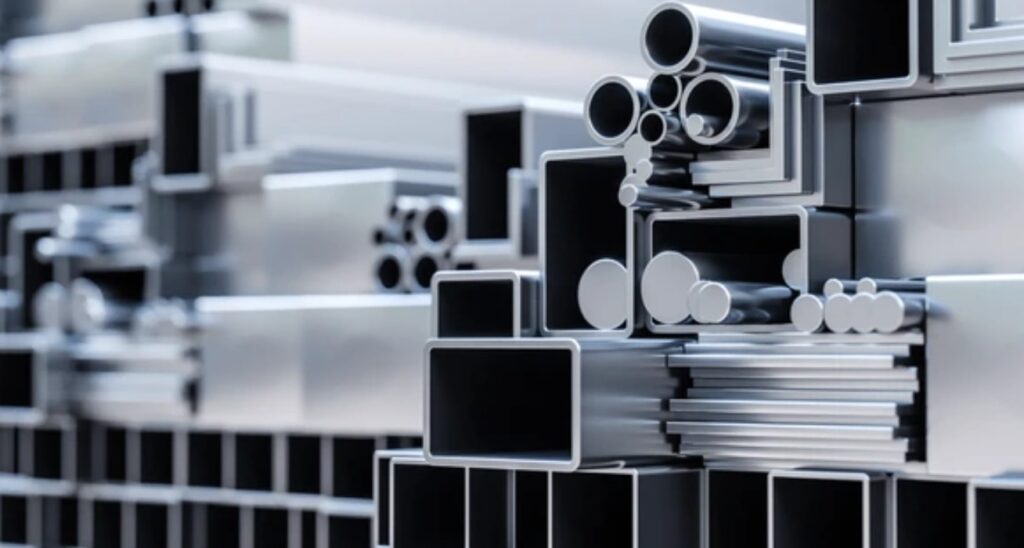

Yes, aluminium is a lightweight silvery-white metal that belongs to Group 13 of the periodic table, known for its strength, conductivity, and corrosion resistance.

Aluminium is widely used in construction, aerospace, fabrication, and everyday products because it combines durability with low weight.

Why Aluminium Qualifies as a Metal

Aluminium qualifies as a metal because it has metallic bonding, conducts heat and electricity, and shows key traits such as strength, malleability, and ductility. It also belongs to Group 13 of the periodic table, where metals dominate, and naturally forms an oxide layer that protects it from corrosion, making it one of the most widely used engineering metals today.

- Atomic structure: Metallic bonding in Group 13 of the periodic table.

- Conductivity: Excellent conductor of heat and electricity.

- Mechanical properties: Strong, ductile, and highly malleable.

- Durability: Forms a protective oxide layer that resists corrosion.

Unlike plastics or composites, aluminium retains its metallic identity even after alloying with other elements.

How to Tell If a Metal Is Stainless Steel or Aluminium

Fabricators and buyers often confuse stainless steel with aluminium. You can differentiate them through:

- Weight: Aluminium is much lighter.

- Magnetism: Aluminium is non-magnetic, while some stainless steels may show slight magnetism.

- Appearance: Stainless steel looks shinier, aluminium has a softer, matte finish.

- Strength: Stainless steel is denser and more rigid.

When in doubt, consult professionals. At The Monster Builder, we guide clients in selecting the right material for metal fabrication projects.

How Aluminium Is Alloyed with Other Elements

Pure aluminium is soft, so industries rarely use it in isolation. Instead, engineers alloy aluminium with other elements to enhance strength, durability, and corrosion resistance:

- Copper (Cu): Increases hardness and strength, common in aerospace and automotive parts.

- Magnesium (Mg): Boosts corrosion resistance, ideal for marine and structural applications.

- Zinc (Zn): Provides very high strength, used in aerospace and defence.

- Silicon (Si): Improves wear resistance and casting performance.

These alloys allow us to adapt aluminium for demanding applications, from CNC machining of precision components to 3D printing custom prototypes.

Understanding Aluminium’s Unique Alloys

Aluminium alloys fall into two main categories:

- Wrought alloys – Shaped by rolling, extrusion, or forging. Used in aluminium sheet fabrication and unistrut channel systems.

- Casting alloys – Formed by pouring molten metal into molds. Essential for components produced via SLA 3D printing or FDM 3D printing.

Popular series include:

- 6000-series (Al-Mg-Si): Excellent corrosion resistance, widely used in construction.

- 7000-series (Al-Zn-Mg): Superior strength for aerospace and defense.

These alloys make aluminium adaptable for industries that demand both light weight and strength.

Conclusion

Aluminium is a metal that continues to shape industries worldwide. Its lightweight structure, corrosion resistance, and alloy versatility make it indispensable for modern fabrication.

At The Monster Builder, we specialise in CNC machining, metal fabrication, aluminium sheet fabrication and more to deliver high-quality solutions for you.

FAQs

Is Aluminium Stronger Than Steel?

Steel is stronger, but aluminium is lighter and easier to machine. This makes aluminium alloys the preferred choice for weight-sensitive projects like automotive, aerospace, and modular frameworks.

Can Aluminium Rust?

Aluminium does not rust like steel. Instead, it forms a thin oxide layer that protects it from corrosion, which is why it’s widely used in marine and outdoor applications.

What Are the Common Uses of Aluminium?

In Singapore, aluminium supports multiple industries like construction, manufacturing, prototyping, architecture.