Laser Cutting vs Cnc Milling : Key Differences, Which is Better?

When you build a part in Singapore, you often choose between laser cutting and CNC milling. Both are computer-controlled, both deliver repeatable quality, and both can fit tight timelines. They excel at different things. Laser cutting shines on thin, flat profiles with intricate shapes and clean edges. CNC milling dominates when you need 3D features, threads, pockets, and tight geometric control. This guide explains the differences, shows real use cases, and helps you decide which process suits your part and budget.

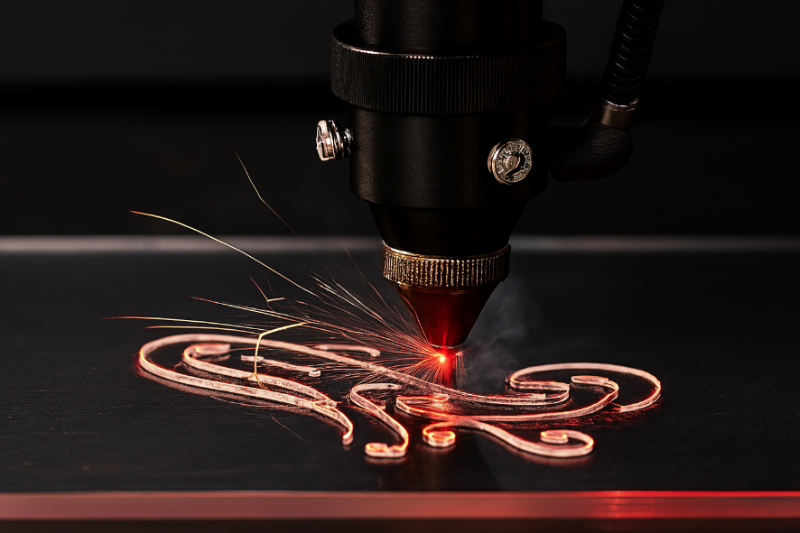

What is Laser Cutting?

Laser cutting is a digital fabrication process that uses a focused laser beam to melt or vaporise material along a programmed path. It creates precise 2D profiles with a narrow kerf and a small heat-affected zone, making it ideal for thin metal and plastic sheets, signage, enclosures, and brackets.

Typical Strengths

- Fast production of 2D profiles and nested parts

- Excellent for small holes, slots, and filigree-like patterns

- Clean edges on stainless steel and aluminium with minimal burr

- Economical for short runs and prototypes in sheet stock

Common Limitations

- Limited ability to create 3D geometry

- Tolerances widen as thickness increases

- Reflective metals and very thick plate may require special setups

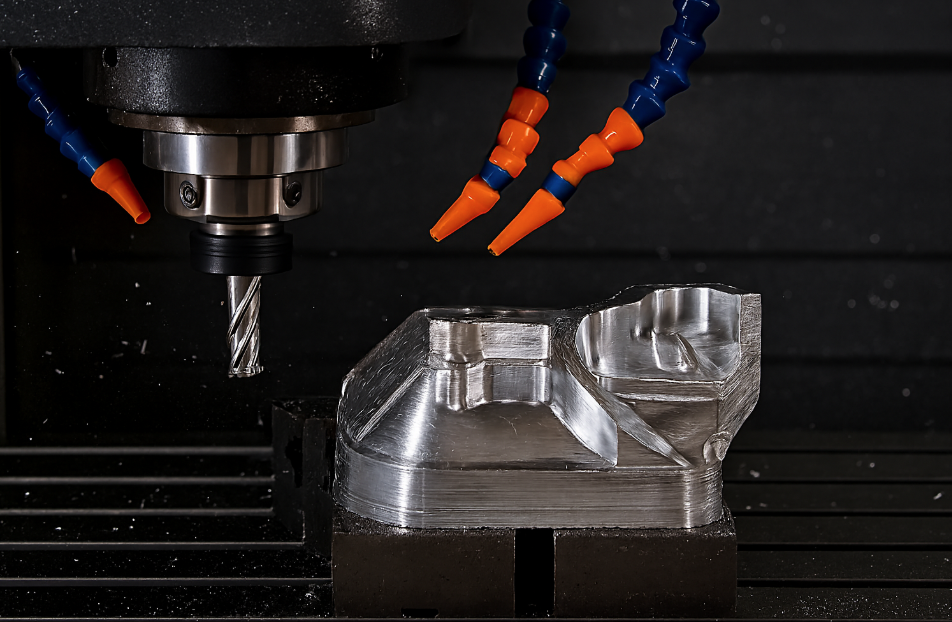

What is CNC Milling?

CNC milling is a subtractive manufacturing process where a rotating cutting tool removes material from a workpiece to create precise 3D shapes. Controlled by a computer, it can machine parts in multiple axes, producing features like slots, threads, and pockets in metals, plastics, and composites with high accuracy.

CNC milling stands out when you need high-accuracy 3D machining. If you’re new to subtractive processes or want a deeper understanding of the machines behind your parts, check out our guide on what a milling machine is and how it’s used in modern manufacturing.

Typical Strengths

- 3D geometry such as pockets, steps, bosses, and chamfers

- Tapped holes, counterbores, and countersinks

- Predictable flatness and surface finish on critical faces

- Works well on thicker stock and complex housings

Common Limitations

- Slower than laser for large 2D cut-outs

- More setup time and tool changes for multi-feature parts

- Tool access can limit deep, narrow features

Difference Between CNC and Laser Cutting

Laser cutting and CNC milling are both highly accurate manufacturing processes, but they work in fundamentally different ways. Here’s a breakdown of the key differences:

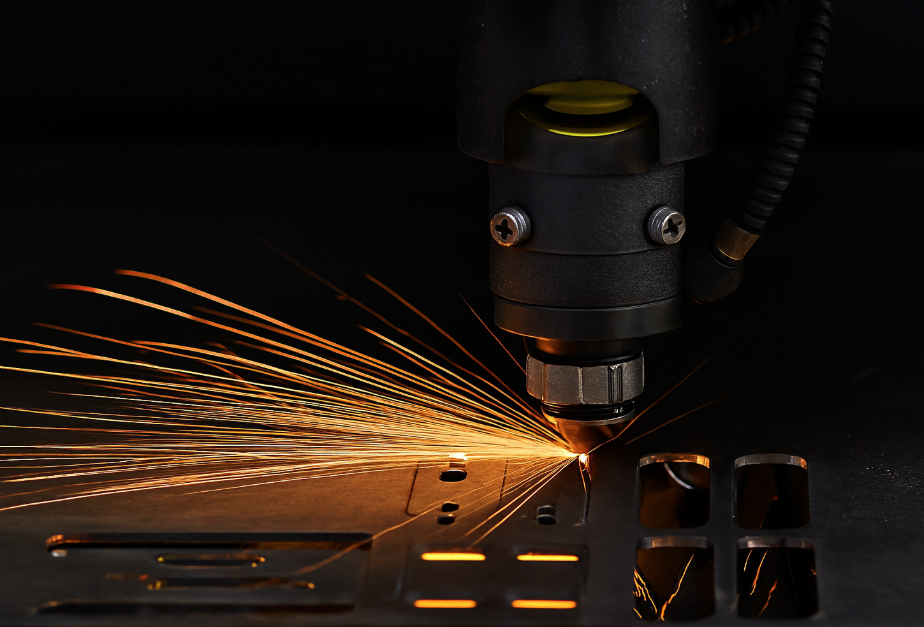

1) Process Mechanism

Laser Cutting

A laser beam focuses on the material, melting, vaporizing, or burning through it. The process is controlled by CNC (Computer Numerical Control), which follows a path defined by the design (usually CAD/CAM data). The beam is non-contact, and the material is often thin sheets.

CNC Milling

CNC milling uses rotating cutting tools (often with multiple blades) to remove material from a workpiece. The process can occur in 3 axes (or more) to create detailed 3D shapes, pockets, threads, and more. This process physically touches the material, removing chips and shavings.

2) Materials and Thickness

Laser Cutting

Best suited for thin materials such as steel, aluminium, plastic, wood, and acrylic. It is commonly used for 2D profiles in sheet metal up to a certain thickness. It struggles with thicker metals and reflective materials like copper and brass unless using specialised equipment.

Mild steel is one of the most common materials used in both laser cutting and milling, especially for structural parts. Discover how mild steel C-channels are used across industries and how the right machining process can enhance their performance and fit.

CNC Milling

CNC milling is effective on a broader range of materials, including thicker metals and plastics. It works well on harder materials like stainless steel, titanium, and engineering plastics. Milling can produce complex 3D shapes from materials of virtually any thickness.

3) Precision and Tolerances

Laser Cutting

The precision of laser cutting typically ranges from ±0.1 mm to ±0.5 mm depending on the material thickness. It’s great for detailed 2D cuts but may not achieve the fine tolerances needed for highly complex parts.

CNC Milling

CNC milling delivers much tighter tolerances, often around ±0.05 mm or better. It’s perfect for parts requiring fine 3D features, like threads or tapped holes, and is ideal for projects that need precise geometries.

4) Surface Finish

Laser Cutting

The edge finish of laser-cut parts is typically clean with minimal burrs. However, depending on the material and thickness, there may be some scorched edges or slight discoloration from the heat affected zone (HAZ).

CNC Milling

Milling can produce a rougher surface finish depending on the cutting tool and cutting conditions. Typically, Ra 3.2 µm is standard for most parts, but you can specify finer finishes depending on the application.

5) Speed and Cost

Laser Cutting

Laser cutting is faster for 2D parts with high complexity (like small holes or slots) and is generally more cost-effective for short runs or prototypes. It’s also faster than milling for cutting flat profiles from sheet material.

CNC Milling

CNC milling is slower compared to laser cutting, especially for simple 2D cuts, but it’s more suitable for 3D shapes and parts with complex features. The cost per part can be higher due to the more involved setup and the multi-stage process.

6) Applications

Laser Cutting

Laser cutting is perfect for parts like signage, electronic enclosures, panels, prototypes, and any parts that require detailed cut-outs or fine patterns on thin metal, plastic, or acrylic sheets.

CNC Milling

CNC milling is best for producing functional components such as mechanical housings, fixtures, jigs, gears, threaded parts, and customised tools. It’s widely used in industries like automotive, aerospace, and medical device manufacturing.

CNC milling is frequently used to create precision features on structural parts like brackets and custom framing components. For example, lip channels and C-purlins used in construction can benefit from both laser cutting for shape and milling for mounting features. Explore more about custom C-purlins in Singapore here.

When selecting materials for laser cutting or CNC milling, understanding your options is key especially when working with carbon steels. Learn more about the 3 main types of carbon steel to choose the right grade for strength, machinability, and finish.

Real Examples of Manufacturing Processes in Singapore

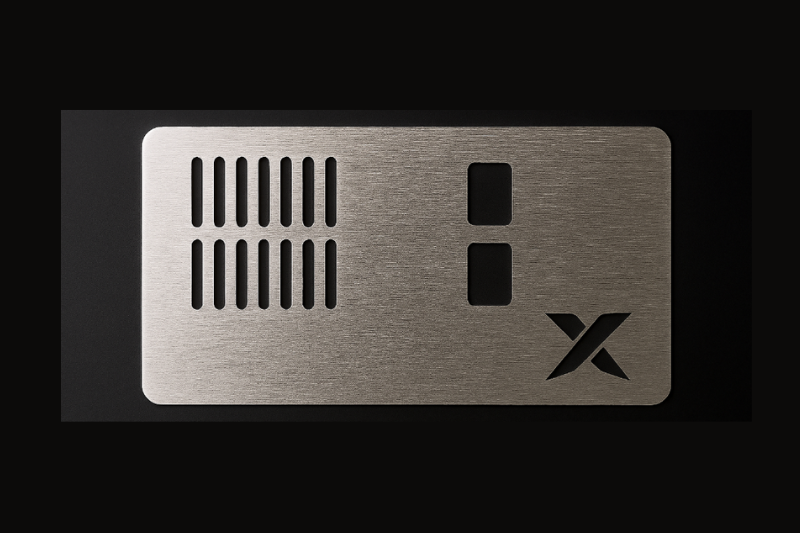

Electronics Front Panel

- Part: 1.5 mm SS304 panel with ventilation slots, USB cut-outs, and a brand logo

- Process: Laser cutting for perimeter and slots, followed by light brushing

- Reason: Dozens of small openings cut quickly with clean edges and minimal burr. Ideal for short lead times and pilot runs.

Precision Fixture Block

- Part: 20 mm aluminium 6061 jig block with M6 threads, reamed dowel holes, and ±0.05 mm flatness on the top face

- Process: CNC milling with a finishing pass on datum faces and thread milling

- Reason: Tight geometry and thread quality demand milling control and stable fixturing for precision.

Hybrid Enclosure

- Part: 2 mm aluminium enclosure with tab-and-slot assembly and a countersunk lid

- Process: Laser cutting for flat blanks and tab features, CNC milling for countersinks and cable-gland pockets

- Reason: Laser cutting reduces costs on the sheet geometry, while CNC milling ensures accurate countersinks and gasket grooves.

Choose the Right Manufacturing Process

If your part has a flat sheet profile with many small holes or slots, needs fast turnaround for prototypes or small production runs, and cosmetic edge quality is important, laser cutting is the best choice.

For parts that require precise threads, counterbores, tight positional tolerances, or include steps, pockets, or sealing surfaces, CNC milling is the ideal process.

If you want to balance low-cost laser blanks with precise machined features, or if your assembly combines decorative panels with functional hardware, consider a hybrid approach. This approach is also useful when scaling from prototypes to production while managing cost and quality.

Conclusion

Whether you’re cutting sleek panels or crafting precision-machined components, selecting the right manufacturing method can make or break your project. Laser cutting is fast, clean, and ideal for 2D profiles, perfect for prototypes, panels, and enclosures. CNC milling, on the other hand, delivers unmatched accuracy for 3D features, tight tolerances, and functional parts that demand mechanical performance.

If your design calls for tight tolerances, threaded holes, complex geometries, or functional prototypes, CNC milling is the clear winner and that’s where we come in.

At The Monster Builder, we provide high-precision CNC machining services in Singapore tailored to your exact needs whether you’re building one part or scaling up for production. With local support, fast lead times, and engineering-grade quality, we help bring your toughest designs to life.