Lip Channels Singapore: Custom C Purlins

What Are Lip Channels?

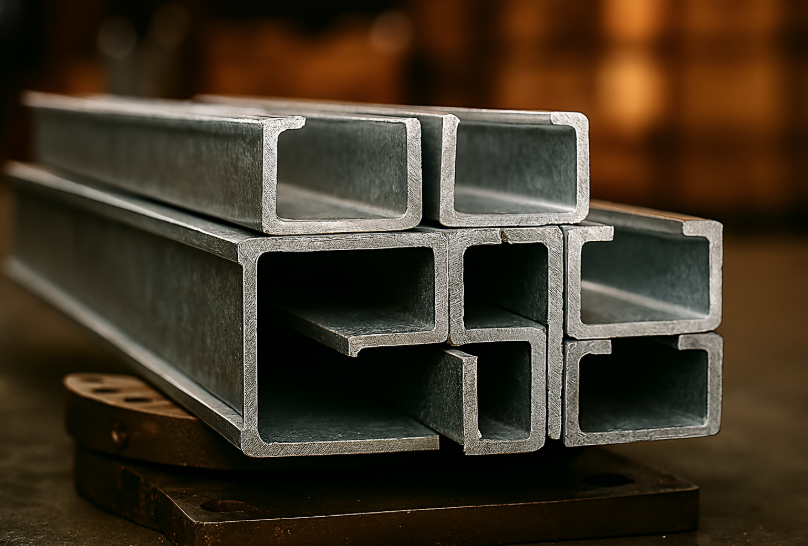

Lip channels, commonly known as C channels or C purlins, feature a distinctive C-shaped cross-section with inward-facing lips on the flanges. Manufacturers form these profiles from hot-rolled mild steel or galvanized steel, incorporating inside radius corners for enhanced durability. The design boosts structural integrity, allowing lip channels to support loads effectively in both horizontal and vertical orientations. Engineers value them for their ease in cutting, welding, forming, and machining, which streamlines fabrication processes.

Applications of Lip Channels

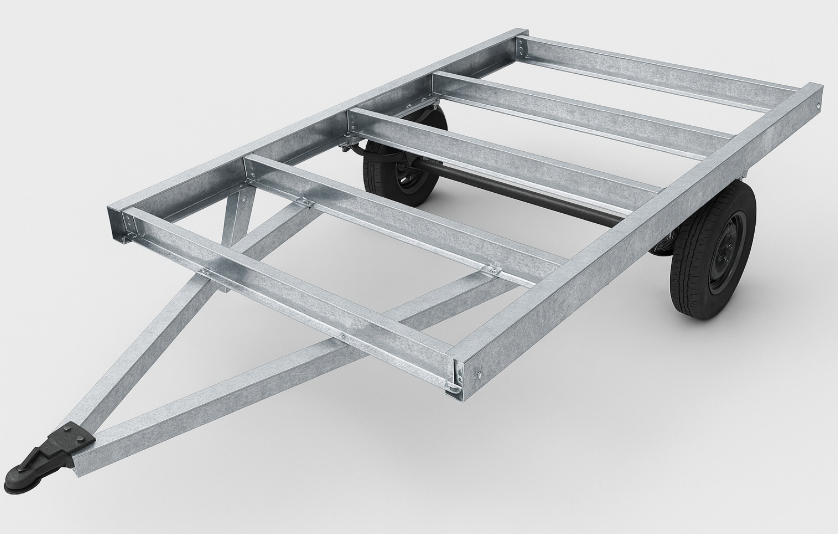

Construction teams rely on lip channels for framing in buildings, roofing supports, and structural reinforcements. Manufacturers integrate them into heavy machinery, agricultural implements, and transportation equipment.

In the automotive sector, they strengthen chassis and frames. General fabrication and industrial maintenance also benefit from their robustness, making lip channels ideal for shelving systems, bridges, and storage solutions across Singapore’s bustling industries.

Common Grades of Lip Channels

We stock lip channels in leading grades to suit diverse requirements. EN 10025 S275 stands out as a mild steel option with excellent machinability and weldability, perfect for general engineering. For corrosion resistance, Z275 galvanized steel offers a 275 g/m² zinc coating, excelling in welding, bending, and fabricating while withstanding rust in harsh environments.

Other popular choices include ASTM A36 for versatile strength, Z350 for heavier zinc protection, and high-tensile grades like G550 (yield strength up to 550 MPa) as per standards such as JIS G 3350 and EN 10162. Stainless steel variants in 304/304L and 316/316L provide superior resistance in marine or chemical settings.

Lip Channels Sizes and Specifications

Monster Builder offers lip channels in a range of dimensions to fit your exact specifications. Widths reach up to 200mm, heights up to 350mm, and lengths up to 12,000mm, with thicknesses starting from 1.0mm. For instance, our standard C purlins include sizes like 100x50x20mm and 150x75x25mm, available in galvanized finishes.

We adhere to international standards like AS/NZS 4600:1996 for cold-formed steel and JIS G 3302 for high-tensile options. Custom cutting services ensure precise fits, and we can supply specialized profiles upon request.

| Grade | Width (mm) | Height (mm) | Length (mm) | Thickness (mm) |

|---|---|---|---|---|

| EN 10025 S275 | Up to 200 | Up to 350 | Up to 12,000 | From 1.0 |

| Z275 | Up to 200 | Up to 350 | Up to 12,000 | From 1.0 |

| ASTM A36 | Up to 200 | Up to 350 | Up to 12,000 | From 1.0 |

| G550 High-Tensile | Up to 200 | Up to 350 | Up to 12,000 | From 1.0 |

| 304/316 Stainless | Up to 200 | Up to 350 | Up to 12,000 | From 3.0 |

Benefits of Lip Channels in Heavy-Duty Applications

Lip channels deliver superior load-bearing capacity, handling substantial weights without deforming thanks to their reinforced lips. They resist stress, buckling, and vibration in high-impact settings like construction sites and industrial plants.

Galvanized versions combat corrosion in moist or chemical-exposed areas, extending lifespan with coatings like hot-dip zinc or powder finishes. Their lightweight design eases installation, cuts labor costs, and boosts efficiency in large-scale projects. Versatility allows seamless integration with beams, plates, and brackets for custom solutions.

Why Choose Lip Channels for Structural Support

Designers select lip channels for their high strength-to-weight ratio, which optimizes material use in roofing, framing, and bracing. In Singapore’s tropical climate, corrosion-resistant options maintain integrity against humidity and rain. They support sustainable building practices by minimizing waste through precise fabrication. Industries appreciate their cost-effectiveness, as durable profiles reduce long-term maintenance and downtime.

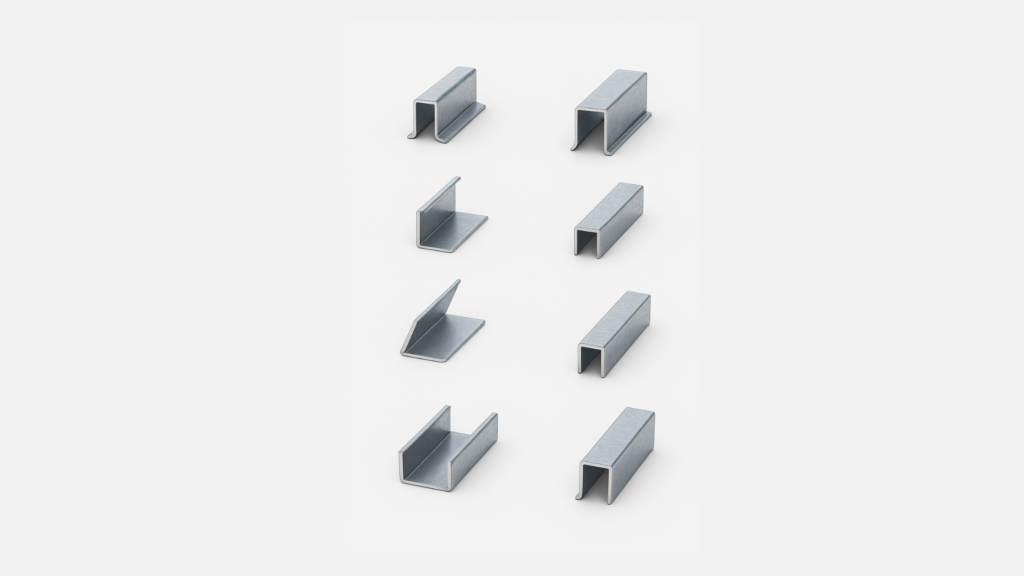

Lip Channel vs C Channel

Lip channels and C channels are C-shaped steel profiles used in construction and manufacturing, but their key difference lies in design and strength. Lip channels feature inward-facing lips on their flanges, providing enhanced rigidity and superior load-bearing capacity, making them ideal for heavy-duty applications like roofing, framing, and machinery in Singapore’s humid climate.

C channels, without these lips, are simpler, lighter, and better suited for non-load-bearing or less demanding tasks, such as basic supports. For example, lip channels in grades like EN 10025 S275 or Z275 offer excellent corrosion resistance, while C channels are more cost-effective for lighter frameworks. Monster Builder supplies both, tailored to your project’s needs.

| Feature | Lip Channel | C Channel |

|---|---|---|

| Design | C-shaped with inward-facing lips | C-shaped without lips |

| Strength | Higher rigidity, load-bearing | Lower, suited for lighter tasks |

| Applications | Roofing, framing, heavy machinery | Basic supports, non-load-bearing |

| Corrosion Resistance | Excellent (e.g., Z275 galvanized) | Varies, often less durable |

| Cost | Higher due to enhanced design | More cost-effective |

About Monster Builder

As a leading metal fabricator in Singapore, Monster Builder delivers premium structural steel products, including lip channels, beams, columns, pipes, and more.

Our inventory spans mild steel, galvanized steel, stainless steel, and aluminum, crafted for construction, manufacturing, and industrial applications. We ensure top-quality through rigorous controls aligned with local and international standards, guaranteeing reliable lip channels for your projects.

Our skilled team provides prompt delivery across the Asia Pacific, serving Singapore’s diverse industries. Contact us via our enquiry form or Singapore office for custom quotes and professional service.