Mild Steel C Channels Uses and Applications

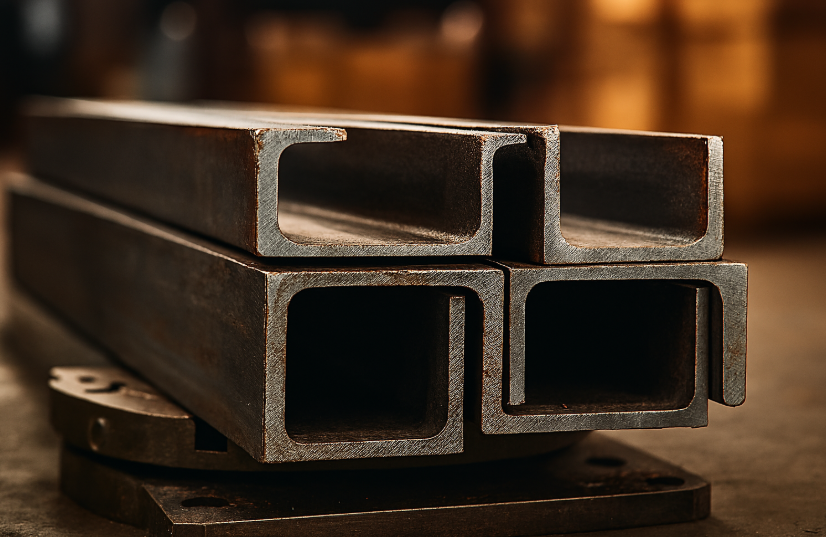

What Is Mild Steel C Channel?

A mild steel C channel is a structural steel beam shaped like the letter “C”, made from low-carbon steel. It consists of a vertical web and two horizontal flanges. Known for its strength, weldability, and cost-effectiveness, it is commonly used in construction, framing, and machinery support structures.

- A vertical web (depth, “h”)

- Two flanges at the top and bottom (width, “b”)

- Fillet radii and slope of flanges in many standards

Properties of typical mild steel (e.g. ASTM A36, SS400, EN S275JR) include:

- Yield strength around 250 MPa (depends on grade and thickness)

- Tensile strength roughly 400‑550 MPa for common plates/shapes

- Density approx 7,850 kg/m³ (or 7.85 g/cm³)

Is C Channel Mild Steel?

C channel can be made from various materials, but mild steel is the most common due to its strength, ductility, and cost-efficiency. A mild steel C channel is typically used in construction, fabrication, and structural support. However, C channels also exist in stainless steel, galvanized steel, and aluminum.

In Singapore, typical mild steel grades used in structural channels include ASTM A36, EN 10025‑S275JR, and SS400.

Steel Grades & Standards Relevant in Singapore

In Singapore, steel used for structural and engineering purposes must comply with recognized international or national standards to ensure safety, quality, and performance. These standards define chemical composition, mechanical properties (like yield and tensile strength), dimensional tolerances, and testing requirements.

Common Steel Grades for Mild Steel C Channels in Singapore

| Steel Grade | Standard | Yield Strength | Description |

|---|---|---|---|

| ASTM A36 | ASTM (USA) | ≥ 250 MPa | General-purpose mild steel with good weldability and formability. Widely used in structural sections like C channels. |

| EN 10025 S275JR | EN (Europe) | ≥ 275 MPa | Hot-rolled non-alloy structural steel. Slightly higher strength than A36. Common in European and Asian markets. |

| EN 10025 S355JR | EN (Europe) | ≥ 355 MPa | High-strength mild steel grade used where stronger structural performance is needed. |

| SS400 | JIS (Japan) | ≥ 245 MPa | A widely used structural steel in Asia, known for its good machinability and weldability. Comparable to A36. |

| BS 4360 Grade 43A | British Standard | ~ 275 MPa | Older British standard (now replaced by EN equivalents), still referenced in some legacy projects. |

Singapore’s Regulatory & Industry Standards

In Singapore, while there isn’t a single “Singapore-only” steel grade, the Building and Construction Authority (BCA) accepts the use of international standards provided they are supported by:

- Mill Test Certificates (MTC)

- Third-party testing reports

- Conformance to design codes such as SS EN 1993 design of steel structures, SS EN 10025 for hot rolled structural steels, SS EN ISO 9001 for quality management for fabricators

BCA & LTA (Land Transport Authority) projects often require steel materials to be certified and traceable, especially for load-bearing applications.

Mild Steel C Channel Standard Sizes & Verified Weight Charts

These sizes are from ISMC (Indian Standard, Medium Channels) which are common globally and among many Asian suppliers. While Singapore does not have a widely published SS standard chart for every channel size, many local suppliers carry these ISMC sizes.

Here is a verified weight chart (kg/m) with dimensions (+ thickness) that are consistently used.

| Section (Designation) | Depth h × Flange b × Thicknesses (Web × Flange) (mm) | Weight per metre (kg/m) |

|---|---|---|

| ISMC 75 × 40 × 4.8 (web ≈ 4.8 mm) | 75 × 40 × ~4.8 | 7.14 |

| ISMC 100 × 50 × 5.0 | 100 × 50 × 5.0 | 9.56 |

| ISMC 125 × 65 × 5.3 | 125 × 65 × 5.3 | 13.10 |

| ISMC 150 × 75 × 5.7 | 150 × 75 × 5.7 | 16.80 |

| ISMC 175 × 75 × 6.0 | 175 × 75 × 6.0 | 19.60 |

| ISMC 200 × 75 × 6.2 | 200 × 75 × 6.2 | 22.30 |

| ISMC 250 × 82 × 9.0 | 250 × 82 × 9.0 | 34.20 |

| ISMC 300 × 90 × 7.8 | 300 × 90 × 7.8 | 36.30 |

| ISMC 400 × 100 × 8.8 | 400 × 100 × 8.8 | 50.10 |

These dimensions and weights are widely used, and many fabricators in Singapore import or stock ISMC channels with similar specs.

What Is C Channel Steel Used For

C channel steel is used in construction, manufacturing, and structural applications. Common uses include building frames, roof purlins, support beams, brackets, machinery bases, scaffolding and metal fabrication. Its C-shaped profile provides strength while reducing weight, making it ideal for both load-bearing and non-load-bearing structures.

For exposure to weather or moist / marine climate (like Singapore’s tropical, humid environment), mild steel C channels should be plated, galvanized, painted, or specified with corrosion allowances. Using protective coatings is essential for durability.

Mild steel C channels are widely used in metal fabrication projects, including frameworks, machinery bases, and construction supports, due to their strength and versatility.

To enhance structural safety, mild steel C channels are often paired with chequered plate flooring or walkways, providing excellent slip resistance and durability.

Mild Steel C Channel Weight Charts

Verified Weight Chart (Selected Sizes)

| ISMC Size | Weight (kg/m) |

|---|---|

| 75 × 40 × 4.8 | 7.14 |

| 100 × 50 × 5.0 | 9.56 |

| 125 × 65 × 5.3 | 13.10 |

| 150 × 75 × 5.7 | 16.80 |

| 175 × 75 × 6.0 | 19.60 |

| 200 × 75 × 6.2 | 22.30 |

| 250 × 82 × 9.0 | 34.20 |

| 300 × 90 × 7.8 | 36.30 |

| 400 × 100 × 8.8 | 50.10 |

Calculation Formula

To calculate the theoretical weight per metre:

Weight (kg/m) = Cross‑sectional Area (in mm²) × Steel Density (≈ 7,850 kg/m³) ÷ 1,000,000

Where:

- Cross‑sectional area = area of the “web” + area of both “flanges”

- Fillets, rounding tolerances slightly increase actual area in rolled sections.

Example: For ISMC 100 × 50 × 5.0:

- Web: 100 mm × 5.0 mm = 500 mm²

- Flanges: 2 × (50 mm × 5.0 mm) = 500 mm²

- Total = 1,000 mm² = 0.001 m²

- Weight ≈ 0.001 × 7,850 = 7.85 kg/m theoretical.

- ISMC published is 9.56 kg/m – the difference is due to slope of flanges, web taper, flange thickness at certain points, radius, etc. Therefore always use standard chart for precise applications.

Difference Between MC Channels and C Steel Channels

MC channels refer to Medium-weight C-shaped steel channels, typically following Indian Standard (ISMC) dimensions. C steel channels is a general term for any C-shaped structural steel member. While all MC channels are C channels, not all C channels follow MC/ISMC specifications or weight classes.

In Singapore, suppliers often use ISMC sizes but may also reference EN/BS or ASTM channel equivalents. For example, Kian Huat Metal includes EN 10025 S275JR & S355JR alongside ASTM A36, SS400 in their mild steel channel offerings.

Why Choose Our Mild Steel C Channels?

Our mild steel C channels offer premium quality, precise dimensions, and certified grades like ASTM A36 and S275JR. We provide fast local delivery in Singapore, custom fabrication, and mill test certificates for assured strength and compliance, ideal for construction, engineering, and industrial projects.

While mild steel is common, for higher corrosion resistance, we also offer stainless steel 304 channels suitable for demanding environments.

Conclusion

At The Monster Builder, we combine technical expertise, certified quality, and local knowledge to deliver high-performance mild steel C channels that meet Singapore’s structural and regulatory requirements. Whether you need standard ISMC sizes, custom fabrication, or fast local delivery, we’ve got you covered.

With mill test certificates, internationally recognized grades (like ASTM A36, S275JR, SS400), and full support from our engineering team, we ensure your project gets the strength, accuracy, and compliance it deserves.