Nylon vs Polyester: Differences, Uses, & Which to Choose

What Is Nylon?

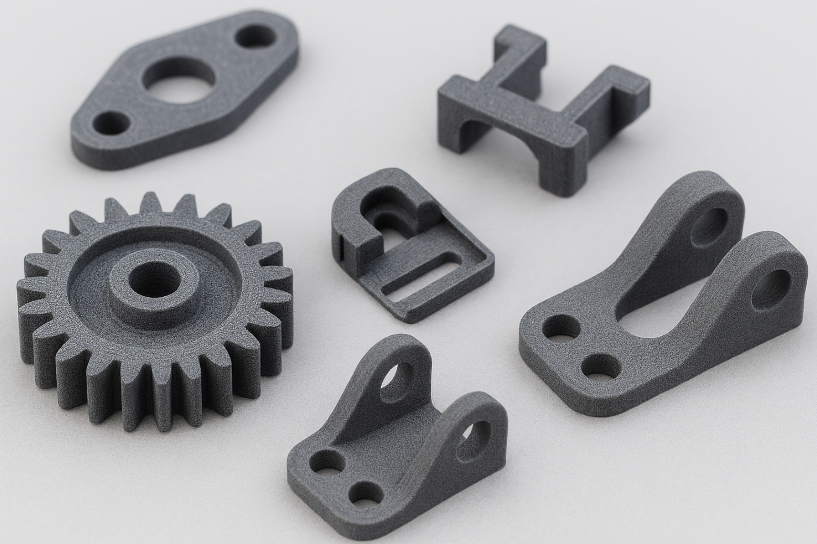

Nylon is a family of synthetic polymers known as polyamides, created by linking repeating amide units to form a strong, lightweight, and versatile engineering plastic. It offers high tensile strength, impact and wear resistance, and moderate moisture absorption, making it ideal for gears, bearings, and industrial parts produced by CNC machining, plastic injection molding, and 3D printing.

- Key Properties: High tensile strength, impact and fatigue resistance, self-lubricating surface, moderate moisture absorption (2–4%), good wear resistance.

- Caveats: Needs UV stabilization for outdoor use, moisture uptake can cause swelling, must be dried before injection molding.

What Is Polyester?

Polyester is a family of synthetic polymers, most commonly polyethylene terephthalate (PET) and polybutylene terephthalate (PBT), valued for its low moisture absorption, strong UV and chemical resistance, and excellent dimensional stability. It is widely used in housings, connectors, textiles, and engineered components produced through plastic injection molding, CNC machining, and 3D printing.

- Key Properties: Very low moisture absorption (<1%), excellent UV and chemical resistance, strong dimensional stability, cost-effective for volume production.

- Caveats: Generally less impact-resistant than nylon unless reinforced; some grades soften earlier under sustained high heat.

Nylon vs Polyester: Key Differences

Nylon and polyester are both durable engineering plastics, but they differ significantly in moisture absorption, UV resistance, impact strength, and dimensional stability. Nylon (polyamide) offers higher toughness and wear resistance, making it ideal for gears, bearings, and high-load components. Polyester (PET or PBT) absorbs far less moisture, resists UV and chemicals better, and maintains tighter tolerances, making it preferred for housings, connectors, and outdoor applications.

| Factor | Nylon (PA6/PA66) | Polyester (PET/PBT) |

|---|---|---|

| Tensile Strength & Toughness | Higher impact resistance, fatigue strength | Stiffer, lower moisture uptake but less impact absorption |

| Moisture Absorption | 2–4%, swelling & dimensional change | <1%, stable dimensions even in humid conditions |

| UV Resistance | Needs stabilization | Inherently better UV resistance |

| Heat Performance | High continuous use temp when dry, can hydrolyze in hot humidity | Good heat stability but may soften under load |

| Chemical Resistance | Good vs oils & hydrocarbons, weak vs strong acids/alkalis | Better resistance to many chemicals, less hydrolysis risk |

| Cost & Processing | Typically higher cost, needs drying | Lower cost, easier processing |

| Fabrication Suitability | Excellent for CNC machining, plastic injection molding high-load parts | Excellent for outdoor housings, connectors, dimension-critical parts |

Nylon vs Polyester Applications & Uses

Nylon and polyester each excel in different manufacturing applications depending on strength, stability, and environmental conditions. Nylon is favored for high-load parts such as gears, bearings, and industrial fittings produced via CNC machining or plastic injection molding. Polyester is preferred for housings, electrical connectors, and outdoor components where low moisture absorption, UV resistance, and tight tolerances are critical.

| Applications | Nylon Advantages | Polyester Advantages |

|---|---|---|

| Gears, bushings, bearings | Wear, fatigue, self-lubrication | – |

| Outdoor housings/enclosures | – | UV stability, low moisture |

| Electrical connectors | High dielectric, mechanical strength | Dimensional stability, chemical resistance |

| 3D Printing (FDM) | High strength nylon filaments, needs drying | PETG filaments easier to print, less warpage |

| Injection molded precision parts | High load capacity | Lower shrinkage, better tolerances |

In our internal testing at The Monster Builder, we printed identical brackets in PA6 nylon filament and PETG polyester filament under the same printer settings. The nylon part withstood 25% more impact load, while the PETG part retained its dimensions better after 48 hours at 85% relative humidity.

Need brackets or housing produced in nylon or PETG? Explore our FDM 3D printing services or plastic injection molding services to bring your prototypes into production.

Cost Comparison: Nylon vs Polyester

Nylon generally costs more than polyester because it requires higher-grade raw materials, drying before processing, and tighter humidity control during molding. Polyester resins are typically less expensive, process faster, and produce fewer rejects, making them more cost-effective for high-volume parts. However, long-term costs depend on performance needs, part lifespan, and environmental conditions.

Alternatives to Nylon and Polyester

- Polycarbonate (PC) for impact and transparency

- ABS, PETG for easier 3D printing or lower-cost parts

- Acetal (POM) for tight tolerances, low friction

- High-performance polymers (PPS, PEEK) for high temp/chemical exposure

- Metals via CNC machining or metal fabrication for heavy duty needs.

Conclusion

Choosing between nylon and polyester comes down to understanding your part’s load requirements, environmental conditions, dimensional tolerances, and cost targets. Nylon offers higher impact strength and wear resistance, while polyester excels in UV stability, chemical resistance, and dimensional precision. By evaluating these factors along with alternatives like polycarbonate, PETG, or metals. You can select the material that best meets your project’s performance and budget goals. Can’t decide? Contact us for help.