Menu

Get durable, affordable parts fast with FDM (Fused Deposition Modeling) / FFF filament 3D printing in Singapore. We print functional prototypes, jigs, fixtures, and enclosures in PLA, ABS, PETG, Nylon/PA, TPU, PC and more, optimized for strength, accuracy, and lead time. Upload your STL/STEP/IGES for a same-day quote.

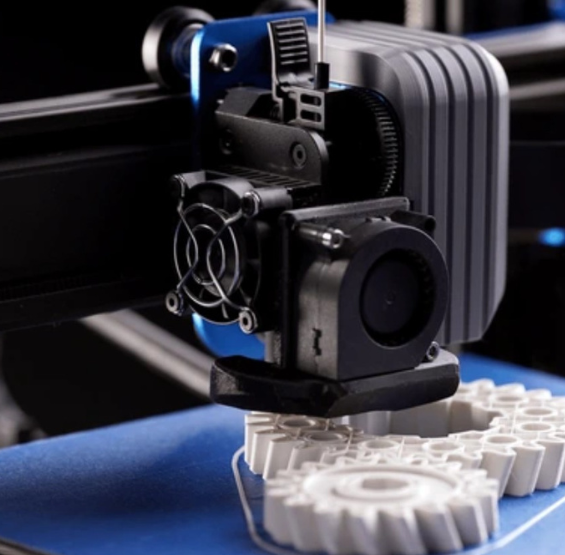

FDM (Fused Deposition Modeling), also called FFF (Fused Filament Fabrication), is a filament 3D-printing process that melts thermoplastic and deposits it layer by layer along a toolpath to build your part. It delivers the best value for rapid prototypes, functional fixtures, and larger parts with fast turnaround.

Product design, manufacturing, electronics, education, architecture, and robotics teams use FDM for rapid prototyping, low-volume production, and functional testing when they need durable thermoplastic parts fast.

Looking for ultra-smooth, fine details or clear parts? Check our SLA Resin 3D Printing Singapore.

Whatsapp or email your drawings

We'll provide a quote within 24 hours

Proceed with fabrication, deliver within 10 working days

Choose FDM 3D printing when cost, speed and durability matter. We extrude real thermoplastics layer by layer to produce strong, dependable parts with configurable layer heights, infill and wall thickness, plus optional sanding/painting and threaded inserts. It’s a reliable, local solution for rapid prototyping and low-volume production across Singapore.

FDM 3D Printing is one of the most cost-effective ways to turn designs into working prototypes. When compared to SLA and SLS printing services, FDM 3D Printing is a cheaper and more cost-effective way to design and test. FDM printing also helps to cut down on the cost of colouring and surface finishing because the designs come out coloured with a workable surface and finish.

Just like all 3D printing services, FDM 3D Printing in Singapore allows local designers and engineers to test functionality in a fraction of the time when compared to traditional manufacturing processes. Where traditional manufacturing can take months, FDM 3D printing Singapore can be complete in a matter of days.

FDM 3D Printing uses more than 10 different varieties of plastic filaments from low strength materials, right the way through to high-strength materials. Because you can choose your material based on your intended usage, FDM 3D Printing means greater flexibility.

Fused filament fabrication (FFF) can be used across a wide range of different applications. Whether you’re a hobbyist, you’re testing a new design, or you require fast turnaround on a low-volume product, FDM 3D Printing allows designers to create working models across a range of different industries from jewellery, to automotive, to models, to medical equipment. Rapid 3D printing is a fast, cost-effective way to test designs and ensure functionality before heading to full-scale production.

Don’t see your filament? Ask us! we can source engineering-grade and composite filaments

EXCELLENTTrustindex verifies that the original source of the review is Google. 1st time liaise with them. Prompt response with excellent service. Thank you, Super Tomato.Posted onTrustindex verifies that the original source of the review is Google. Items seems sturdy and the team is quick to respond. One thing is the wheels used for the partition can be changed to something more study but the team is quick to provide remedy (i.e., provide more wheels) for free.Posted onTrustindex verifies that the original source of the review is Google. Very patient with me on the design, fast and efficientPosted onTrustindex verifies that the original source of the review is Google. Very prompt replies and work done by them are perfect, to-spec. Great rates and also fussy free process from conversation to delivery. Amazing company to work with, for prototyping too!Posted onTrustindex verifies that the original source of the review is Google. The best help I got so far getting my product designed.. and five star coordination with the factory. Thank you ????Posted onTrustindex verifies that the original source of the review is Google. Good communication, always receive fast replies for my enquiries. Had them made a couple prototype for my project, and the product received was done exceptionally. Highly recommended!Posted onTrustindex verifies that the original source of the review is Google. Good people , good jobPosted onTrustindex verifies that the original source of the review is Google. They are quick on the replies, providing quotation and easy to communicate. Items received were as promised with minimal delay but from overseas. However, package came damaged but items were so well packed, no damages on the items. Finishing Tolerance of items were mostly to spec but don't expect extreme tolerance limits (+/- 0.1mm). Overall satisfied and happy with the CNC fabrication.Posted onTrustindex verifies that the original source of the review is Google. Posted onTrustindex verifies that the original source of the review is Google. Great communication! Work was efficient and of high quality.

FDM typically achieves ±0.5% (≥±0.5 mm), with ±0.2 mm possible on optimized geometries. SLA offers finer cosmetics, FDM wins on strength and value.

For general strength and heat resistance, choose PETG, ABS, PC, or Nylon/PA. For impact and wear, Nylon/PA or CF-Nylon (on request). For flexibility, TPU.

Yes. Larger parts are printed in sections and bonded with alignment features.

Most FDM orders ship within 2–5 working days depending on part size, quantity, and finishing. Rush slots available.

STL, STEP, IGES. Include units (mm), wall thickness, and any critical tolerances.

Pioneering Automation and Robotics solutions for diverse industries, enhancing efficiency, productivity, and innovation

Our Location

Singapore Headquarters:

15 Little Rd, #04-02, Singapore 536988