Sheet Metal Laser Cutting Price: Factors & Cost

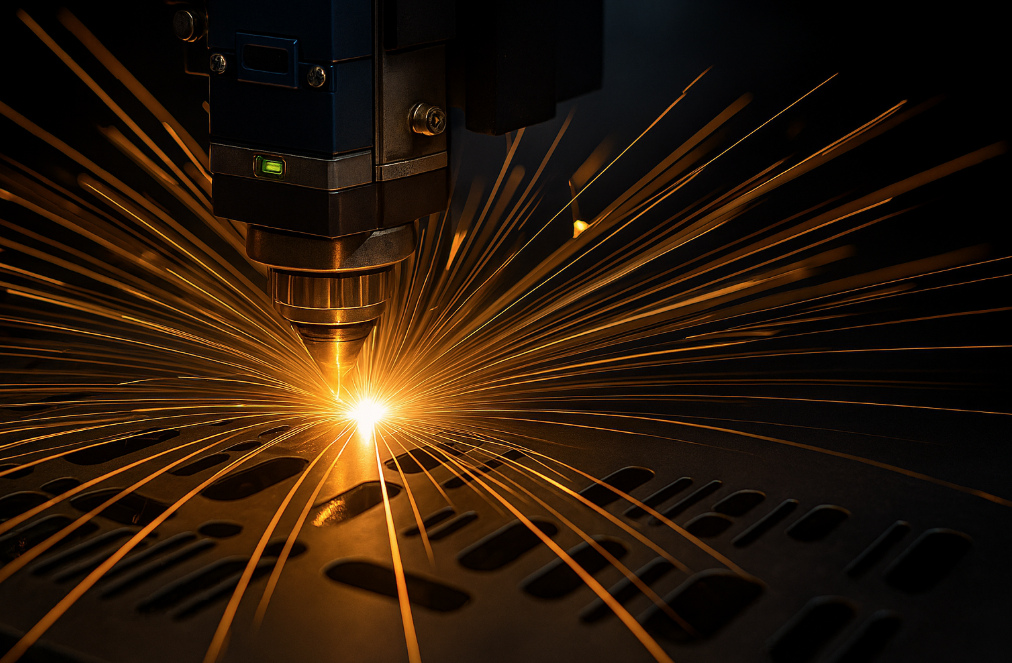

When it comes to precision manufacturing, sheet metal laser cutting is one of the most efficient and cost-effective methods available. Whether you’re creating prototypes, custom components, or high-volume production parts, understanding sheet metal laser cutting prices is essential for accurate budgeting and project planning.

What Drives Sheet Metal Laser Cutting Prices

Before you request a quote or compare vendors, it’s important to understand what actually affects the cost of laser cutting sheet metal. Prices aren’t just based on size or material. They reflect a combination of technical and operational factors that influence how long a job takes, how much material is used, and how complex the process becomes.

In Singapore, where labor, utilities, and precision standards are high, even small design changes can significantly impact the final cost. By knowing what drives pricing, you’ll be better equipped to estimate your project costs, avoid unexpected charges, and make informed decisions when choosing a laser cutting service.

When preparing your design files, it’s also useful to understand finishing techniques such as chamfer vs fillet which can influence both aesthetics and cost.

Material Type & Thickness

The type of metal (e.g. mild steel, stainless steel, aluminium) and its thickness are among the strongest cost drivers. Metals with high density or reflectivity (like stainless steel or aluminum) often require more power or multiple passes. Thicker sheets slow the cutting speed, increasing machine time. For example, cutting a 2 mm mild steel plate costs less per meter of cut than cutting 5 mm stainless steel under the same design complexity.

| Material Thickness | Estimated Price per Meter of Cut | Use Case Example |

|---|---|---|

| 1.0 mm – 1.5 mm | S$1.50 – S$3.00 | Signage, electronic enclosures |

| 2.0 mm – 3.0 mm | S$2.50 – S$5.00 | Brackets, panels, light structures |

| 4.0 mm – 6.0 mm | S$4.50 – S$8.00 | Industrial parts, frames |

| 8.0 mm – 12.0 mm | S$8.00 – S$15.00 | Heavy-duty parts, structural work |

Note: These prices are based on mild steel. Stainless steel and aluminium typically cost 15–30% more due to material and machine requirements (e.g. slower speed, higher power, gas usage).

Cut Complexity & Geometry

Simple straight-line cuts are faster. Intricate shapes, tight curves, internal holes, small slits or micro‑features force the laser to slow down or do multiple passes. Those complexity costs show up directly in the quote.

Machine Operating Costs & Setup

The cost to run the laser (electricity, maintenance, depreciation) plus setup time (calibrating, aligning, test cuts) all contribute. Each job often has a fixed setup portion before the cutting even begins.

Order Quantity & Batch Size

Larger quantities allow fixed costs (programming, setup) to be amortized across many parts, driving the per-piece cost down. Small one-off jobs usually carry a higher per-part cost.

Finishing & Post-Processing

Deburring, polishing, painting, coating, or adding bends or other secondary operations all add to the total. Often post‑processing can equal or exceed the cutting cost, depending on finish spec.

If you’re unsure whether laser cutting or CNC milling suits your needs best, our detailed guide on the key differences between laser cutting and CNC milling will help you decide.

Common Sheet Metal Laser Cutting Price Lists in Singapore

Sheet metal laser cutting costs vary depending on the type of metal being processed. Below are average price estimates in Singapore for the most commonly used materials. These ranges reflect standard industry pricing based on cutting length (per meter) and material thickness.

Mild Steel Sheet Laser Cutting Price

Mild steel is the most economical and widely used material for laser cutting. It offers good machinability and is ideal for structural, automotive, and general fabrication work.

| Thickness | Estimated Price (Per Meter of Cut) |

|---|---|

| 1.0 – 1.5 mm | S$1.50 – S$2.50 |

| 2.0 – 3.0 mm | S$2.50 – S$4.00 |

| 4.0 – 6.0 mm | S$4.00 – S$6.50 |

| 8.0 – 12.0 mm | S$6.50 – S$10.00 |

Stainless Steel Sheet Laser Cutting Price

Stainless steel is more expensive to cut due to its reflectivity and slower cutting speed. It’s used in architectural, food-grade, and corrosion-resistant applications.

| Thickness | Estimated Price (Per Meter of Cut) |

|---|---|

| 1.0 – 1.5 mm | S$2.50 – S$3.50 |

| 2.0 – 3.0 mm | S$4.00 – S$6.50 |

| 4.0 – 6.0 mm | S$6.50 – S$9.50 |

| 8.0 – 12.0 mm | S$10.00 – S$15.00 |

Aluminum Sheet Laser Cutting Price

Aluminium requires high laser power and proper gas assist due to its heat conductivity. It’s popular in aerospace, automotive, and lightweight structural designs.

| Thickness | Estimated Price (Per Meter of Cut) |

|---|---|

| 1.0 – 1.5 mm | S$2.50 – S$3.50 |

| 2.0 – 3.0 mm | S$3.50 – S$5.50 |

| 4.0 – 6.0 mm | S$5.50 – S$8.50 |

Understanding the material you’re working with is key to optimizing both cost and quality. For example, if you’re working with aluminium, knowing about different aluminium flat bar sizes and uses can help you select the right profile for your project.

Iron Sheet Laser Cutting Price

Iron (or general carbon steel) offers durability but may require additional finishing due to oxidation. Pricing is comparable to mild steel but can vary depending on grade.

| Thickness | Estimated Price (Per Meter of Cut) |

|---|---|

| 1.0 – 1.5 mm | S$1.80 – S$3.00 |

| 2.0 – 3.0 mm | S$3.00 – S$5.00 |

| 4.0 – 6.0 mm | S$5.50 – S$9.00 |

The prices listed above are general estimates based on current market rates in Singapore and are provided for reference purposes only. Actual costs may vary depending on material grade, cut complexity, order quantity, and specific job requirements.

For an accurate and customized quote, please contact our team with your technical drawings or specifications.

How Is Laser Cutting Cost Calculated?

Here’s a breakdown you can use (or request from suppliers) to see how a laser cutting quote is built up.

Material Cost Allocation

Estimate cost of raw sheet metal portion. For example, if a job uses 1 m² of 2 mm stainless steel priced at S$50/m², that is your base material cost.

Cutting Time & Length Cost

Based on the total cut length (in meters) and the machine’s speed. If your design has 20 m of cut and the machine speed is 5 m/min, that’s 4 minutes of cutting. Multiply by machine hourly rate.

Setup & Labor Overhead

Add fixed setup time (e.g. 15–30 minutes) and labor cost for preparing, loading/unloading, aligning, test runs.

Waste & Scrap / Yield Factor

Account for material lost due to kerf width, unusable offcuts, nesting inefficiency. Many fabricators allocate an additional 5–20% buffer. In practice, some laser-cutters on forums mention applying a 30% markup to cover losses.

Margin / Risk Buffer

The supplier adds margin or contingency for machine downtime, error rework, or overhead.

Post-Processing & Finishing

Finally add costs for deburring, surface finish, coating, bending, etc.

Example Calculation:

- Material: S$50 for 1 m² of stainless

- Cut length: 20 m at S$10 per meter = S$200

- Setup & labor: S$30

- Waste buffer (10%): +S$5

- Post-processing: S$20

Total = S$305, or per-part cost depending on how many parts are produced.

Local Prices & Estimates Costs

While actual quotes vary, here are sample estimates and local data to guide expectations:

- In Singapore, generally a simple laser-cut parts may cost around S$5 to S$20 per square centimeter for straightforward cuts on common metals, depending on thickness and complexity.

- Locally, many laser‑cutting firms claim they can cut up to 20 mm mild steel, 6 mm aluminium, 12 mm stainless steel.

These local data points help you benchmark any quote you receive.

Factors That Influence the Price in Singapore

While the basic cost drivers are universal, Singapore has some specific cost elements:

- Electricity & utilities: Singapore’s electricity tariffs affect machine running cost.

- Manpower & labor: Skilled operator wages in Singapore are relatively high.

- Floor space & rent: Workshop rental costs in industrial zones affect overhead allocation.

- Material sourcing/import duties: Whether metal sheets are locally procured or imported can add cost and lead time.

- Urgent / rush orders: Suppliers may impose rush fees of 20–50% extra for expedited jobs.

- Machine availability & capacity: If many jobs queue up, providers may charge premium for priority.

How to Estimate Cutting Price Yourself

If you want to ballpark a laser-cutting cost before asking for quotes:

Use this rough rule:

Cost = (Material cost) + (Cutting length × machine rate) + Setup + Waste buffer + Finishing

As a rule of thumb, add 10–20% overhead for waste and unexpected inefficiencies.

Build a simple spreadsheet:

- Input material unit cost,

- Input total cut length,

- Input machine cost per meter or per minute,

- Add fixed setup,

- Add finishing cost.

Always ask your vendor to show cut length and machine time breakdown transparency helps you compare apples to apples.

Conclusion

Understanding sheet metal laser cutting prices is just the beginning. At The Monster Builder, we offer end-to-end metal fabrication services in Singapore, not only precision laser cutting but also aluminium sheet fabrication, CNC milling, welding, bending, and surface finishing.

Whether you’re working on custom enclosures, industrial machine parts, architectural components, or prototypes, we combine advanced machinery with skilled craftsmanship to deliver quality, speed, and reliability.

If you’re looking for a trusted partner for laser cutting and beyond, we’re ready to help you turn your designs into real, functional parts fast and affordably. Contact us now!