Universal Beam Sizes Properties and Applications

What Is a Universal Beam?

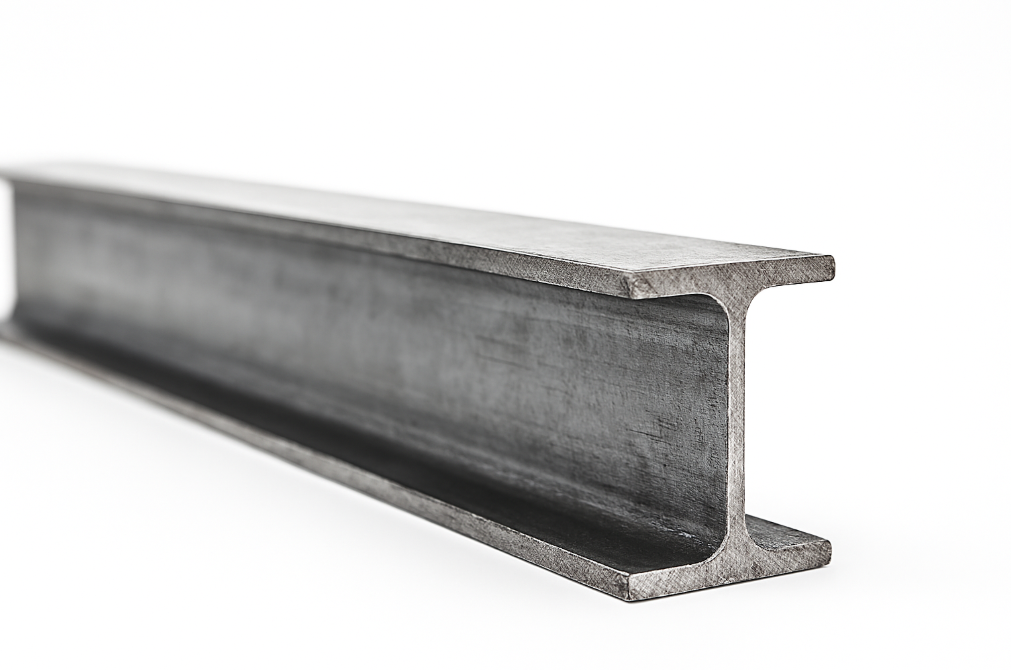

A universal beam (UB) is a hot-rolled steel section with an “I/H” profile: a central web and two parallel flanges. Contractors and engineers use UBs as primary load-bearing members because they deliver high bending strength while keeping weight efficient. In Singapore projects, you’ll commonly see UBs in floor beams, roof rafters, transfer beams over large openings, and temporary works like needle beams.

On a drawing you’ll see: depth × width × mass (kg/m), for example UB 254×146×31, plus a grade such as S275 or S355.

Shape: I/H with parallel flanges

Role: Resists bending and shear in floors/roofs and over openings

Grades seen in SG: SS-EN 10025 S275 / S355 (ASTM A36 may appear on imports, verify with your PE)

Alongside primary UB members, site teams often need secondary sections for trims and supports. Our stainless steel U-channels handle neat finishes and corrosion-prone areas in Singapore builds

What Is the Difference Between RSJ and Universal Beam?

RSJ stands for Rolled Steel Joist. It’s an older UK term that people often use (sometimes loosely) to mean a steel “I-beam.” Historically, RSJs were produced with tapered (not parallel) flanges. You’ll still see “RSJ” on legacy drawings and in casual speech, even when the intention is any steel beam.

RSJ vs Universal Beam (UB) Key Differences

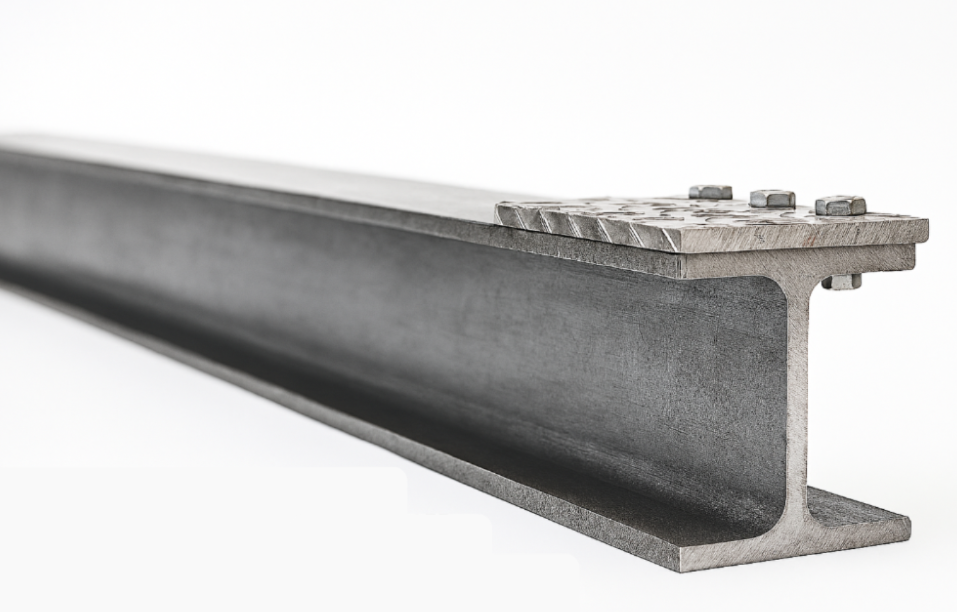

Flange shape

- RSJ: Typically tapered flanges (older sections).

- UB: Parallel flanges (modern standard). Parallel flanges make connection detailing (fin plates, end plates, cleats) faster and more consistent.

Standards & availability

- RSJ: Legacy UK sections; limited/rare in modern stock lists.

- UB: Current, widely available sections to EN/SS-EN (common grades S275 and S355 in Singapore).

Designation

- RSJ: Older joist sizes; naming varied historically.

- UB: Clear depth × width × mass (kg/m) format, e.g., UB 254×146×31.

Design & detailing

- RSJ: Tapered flanges can complicate seating and bolted plate alignment.

- UB: Parallel flanges simplify fabrication, bolting, and welding; easier to standardise holes and plate sizes.

If a drawing says “RSJ,” engineers almost always accept the equivalent UB (same depth/mass/capacity) in the specified grade, unless the notes say otherwise. Always confirm with the PE/engineer.

When replacing legacy RSJs with UBs, you may still need simple, straight members for braces and handrails, specify mild steel round bars to keep details uniform and easy to fabricate.

In Singapore, projects commonly specify UBs to EN/SS-EN grades (S275/S355). “RSJ” appears mainly on legacy/UK-origin drawings in renovations or fit-outs. For supply and compliance, use UB unless the engineer explicitly requires a legacy section.

Properties of a Universal Beam

When you order or substitute a UB, confirm these properties against the design:

- Depth × Width × Mass (kg/m): defines the section size (e.g., 203×133×25 UB)

- Section Modulus (Z) & Second Moment of Area (I): govern bending strength and deflection

- Web & Flange Thickness: affect shear capacity and connection detailing

- Steel Grade (Yield Strength): S275 vs S355 influences span/load and welding behaviour

- Finish/Protection: mill finish, shop primer, or galvanizing depending on exposure

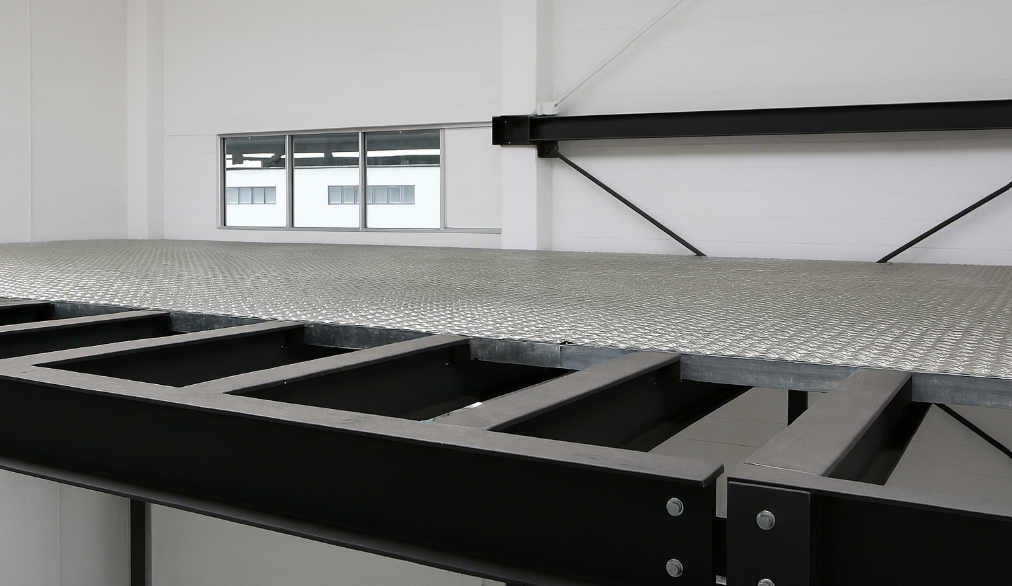

Where slip resistance and drainage matter, plant rooms, service corridors, mezzanines, pair your UB frame with metal grating to improve safety and speed up maintenance.

UB Applications

- Shophouse retrofit: PE specifies UB 203×133×25, S355 as a transfer beam to open a 4–5 m shopfront. We cut to length, weld end plates, and deliver with mill test certificates for submission.

- HDB maisonette renovation: For a wide opening in a non-load-bearing wall that still needs a lintel to carry secondary loads, a compact UB 178×102 with S275 may be used (final size by PE). All HDB structural works require approvals, coordinate early to avoid rework.

- Light industrial mezzanine (Tuas/Woodlands): UB 254×146×31, S355 as primary beams, secondary PFCs, and chequer plate deck. UB’s parallel flanges speed up bolted shear-plate connections and site fit-up.

- Coastal plant room (Jurong Island): Same UB size as above but HDG or duplex paint to handle salt-laden air per specification.

Typical Sizes & Designations You’ll See in Singapore

In Singapore, you’ll commonly see universal beams specified in sizes such as UB 152×89, 178×102, 203×133, 254×146, 305×165, and 356×171, with heavier variants available for higher loads.

Engineers and suppliers use a clear designation format of depth × width × mass (kg/m) to avoid confusion, for example, UB 254×146×31 indicates a beam 254 mm deep, 146 mm wide, with a mass of 31 kg per metre. This convention helps site teams order the correct section, align connections faster, and keep documentation consistent across drawings, fabrication, and delivery.

For exposed floors and access routes, many Singapore jobs specify bulb plates over UB frameworks to reduce slip risk while keeping a clean, durable finish.

Material Grades Commonly Supplied

- S275: dependable mild steel for general structures

- S355: higher yield strength for longer spans/heavier loads with similar weldability

- ASTM A36: appears on some imports, check equivalence and confirm with your PE and submission docs

When Should You Choose a Universal Beam?

Choose a universal beam when your project needs a compact, high-strength member that resists bending efficiently while keeping depth and weight under control.

- Openings and transfers: create wide retail/shopfront openings with a steel lintel/transfer beam

- Mezzanine & floor beams: primary and secondary members for offices, light industrial units, and retail fit-outs

- Roof members: rafters and ridge beams where headroom is tight

- Temporary works: needle beams and propping members with plates and stiffeners

Installation Tips That Save Time On Site

- Match the drawing exactly: verify size and grade before fabrication (e.g., UB 305×165×40, S355).

- Use parallel-flange fittings: end plates, fin plates, and cleats align faster on UBs than on tapered legacy sections.

- Protect exposed steel: specify shop primer, hot-dip galvanizing, or a paint system suitable for marine/coastal zones.

- Level and pre-camber checks: set shims/packers, torque bolts to spec, and recheck deflection after load pick-up.

- Documentation: keep MTCs and welding records, they speed up inspections and submissions.

Conclusion

For Singapore projects that demand strength, speed, and clean detailing, universal beams deliver a reliable solution, especially when paired with the right partner. The Monster Builder provides end-to-end steel fabrication and metal fabrication services tailored to your PE’s drawings: cutting to length, drilling, end plates, base plates, stiffeners, and surface protection (primer, galvanizing, or paint systems).

We supply EN/SS-EN grades with mill test certificates, coordinate island-wide delivery, and package documentation to streamline approvals. Share your UB call-outs and we’ll return a precise, build-ready quote so your beam arrives on time, fits first time, and passes inspection without fuss.