What Is a Heat Sink & How It Works?

What Is a Heat Sink?

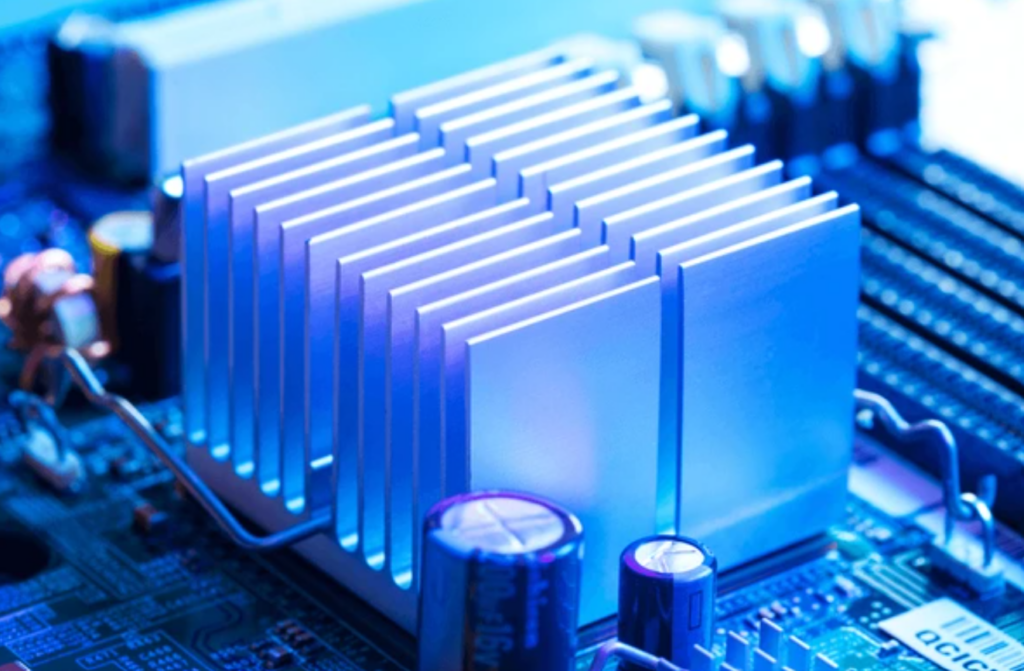

A heat sink is typically a metallic component (or composite) designed to increase surface area in contact with a cooling medium (usually air, sometimes liquid) to remove waste heat. Its purpose is to lower the temperature of a device’s heat-generating part, preventing damage, lowering thermal throttling, and extending lifespan.

Key aspects:

- It is passive (unless combined with fans / forced convection)

- It conducts heat from the source via thermal interface materials (TIMs) or direct contact

- It dissipates heat via convection (air flow), conduction internally, and to a lesser extent radiation

How Does a Heat Sink Work?

The heat sink operates through a chain of thermal processes:

- Heat generation: Component (power transistor, GPU, LED, etc.) generates heat.

- Conduction from source to sink: Heat transfers via base of heat sink and via TIM. The quality of conduction depends heavily on materials (thermal conductivity) and the thermal interface (how well surfaces mate).

- Spreading: Heat spreads across the base (spreading resistance matters, if base too thin, heat doesn’t distribute evenly). Using heat pipes or vapor chambers can ameliorate this.

- Dissipation: Heat leaves via surfaces (fins, pins, microfins) by convection. If airflow is forced (fan or blowers), performance improves. Even natural convection helps. Radiation provides minor cooling, significant only at high temperatures or in vacuum.

Recent trends emphasize miniaturization and high power density devices: more heat per unit area. This pushes designs to include micro-channels, advanced fin/pin geometries, composite base materials, and better TIMs.

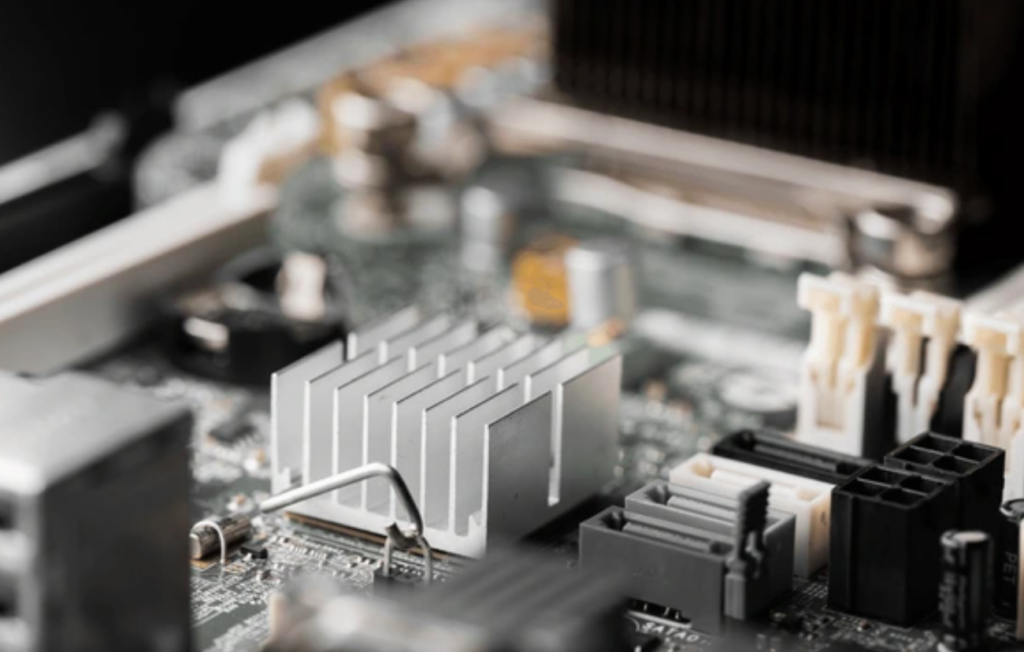

Key Components of a Heat Sink

To meet high performance standards, a heat sink typically includes:

- Base plate (or base body): Solid section contacting the heat source. Thickness and material here affect spreading resistance.

- Thermal Interface Material (TIM or thermal paste / pads / liquid metals): Fills microscopic gaps, lowers interfacial thermal resistance. Critical for maximum conduction. Recent studies show advanced metal-, carbon-, and polymer-based TIMs improving performance in high power electronics.

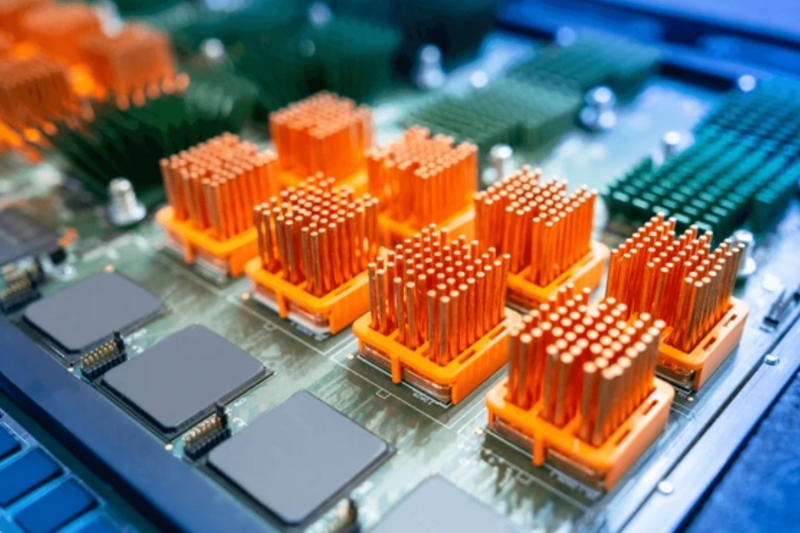

- Fins / Pins / Microfins / Pin-fin arrays: Increase surface area. Shapes vary depending on airflow, cost, and manufacturing method. Fins get thinner, denser in some designs.

- Heat pipes or vapor chambers: Often integrated into base to spread heat quickly from hotspot to rest of sink.

- Mounting / attachment method: Clips, screws, adhesives, and ensuring good mechanical pressure for TIM.

- Surface treatment: Anodizing, coatings, or surface texturing to increase emissivity, protect from corrosion, improve thermal performance.

What Materials Are Heat Sinks Made Of?

Heat sinks are typically made from aluminium or copper because both metals conduct heat efficiently. Aluminium is lightweight, affordable, and easy to manufacture, while copper offers superior thermal conductivity for high-performance applications. Some advanced designs also use hybrid materials such as aluminium-copper composites, metal-matrix composites (like AlSiC), or graphite-based materials for improved performance.

Applications of Heat Sinks

Modern applications of heat sinks are broad and growing, particularly with market demands for compact, high-power, energy-efficient devices. Key areas include:

- Computers & Consumer Electronics: CPUs, GPUs, power banks, chargers, LED lighting. As devices get smaller and more powerful, thermal density rises.

- Industrial / Power Electronics: IGBTs, MOSFETs, inverters, motor drives. Here reliability under high temperature / long duty cycles is critical.

- Automotive & EVs: Battery management, inverter cooling, LED headlights, power electronics. Thermal shocks and vibration require robust design.

- Telecom / Data Centres: Server racks, high-density boards, cooling in limited airflow environments.

- Medical Devices / Aerospace / High Reliability Sectors: Where failure from thermal issues is not acceptable.

At The Monster Builder, our CNC machining metal fabrication and steel fabrication services are well suited for industrial and power electronics heat sink bodies. 3D printing (both SLA and FDM) allows rapid prototyping of housings or parts to test designs.

Plastic injection molding creates housings that integrate heat sink modules or enclosures. Aluminium sheet fabrication is often used for lightweight heat sink fins or skin panels.

Benefits of Heat Sinks

Using a well-designed heat sink offers multiple benefits:

- Extended Product Lifespan & Reliability: Keeps component temperatures lower, reducing thermal stress, electromigration, or failure rates.

- Stable Performance Under Load: Prevents thermal throttling, ensures that performance remains consistent even under heavy usage.

- Energy Efficiency & Lower Cooling Costs: Reduces the need for large fans or active cooling, saving energy and weight (important for mobile / automotive).

- Noise Reduction: Passive or lower-speed cooling often quieter.

- Customisation and Design Flexibility: Via material choice, shape (pins, microfins, vapor chambers), form-factor, and surface treatments.

Morever, better heat sinks can help meet regulatory thermal standards (electronic safety, EMC related thermal considerations, automotive etc.), which improves product acceptance in market.

How to Choose the Right Heat Sink

Key considerations:

- Size / Weight / Form Factor Constraints: Limited space or weight may force use of lighter materials or thinner fins.

- Material Trade-offs: Aluminium vs copper vs composite; cost vs conductivity vs weight vs durability.

- Manufacturability: Can the design be produced cost-effectively? Are there precision constraints? Can your fabrication services (CNC machining, aluminium sheet work, sheet metal fabrication, steel fabrication, 3D printing, injection molding) meet those needs?

- Thermal Interface & Mounting: Quality of TIM, contact surface finish, mounting pressure, mechanical stress, vibration.

Core Components We Deliver

- When prototyping heat sink bases or custom fin geometries, we use 3D printing (FDM and SLA) to validate design airflow, heat spread first.

- For the production of fins, pins, casings, our CNC machining metal fabrication and aluminium sheet fabrication deliver precision in fin thickness, spacing, and overall geometry.

- For heavy structural bodies (motor controllers, industrial heat sink housings), steel fabrication combined with copper inserts or composite plates may be used.

- Use of plastic injection molding can help produce durable housings or covers that integrate with or mount onto heat sink assemblies without interfering thermally.

Conclusion

A well-designed heat sink is more than just a block of metal. It’s a critical thermal management solution that protects components, improves performance, and extends product life. With our CNC machining, aluminium sheet fabrication, 3D printing (SLA & FDM), sheet metal fabrication, steel fabrication, and plastic injection molding capabilities, The Monster Builder can design and manufacture custom heat sinks tailored to your exact specifications.

Contact us today for an instant quote and discover how our advanced fabrication and 3D printing solutions can bring your heat sink project to life in Singapore.