What is the Best Metal Cutting Machine?

Choosing the best metal cutting machine can dramatically improve the speed, accuracy, and cost-efficiency of your manufacturing or fabrication project. Whether you’re looking for a small hand tool or a heavy-duty industrial cutter, this guide will help you make an informed decision based on your needs in the Singapore market.

What Is a Metal Cutting Machine?

A metal cutting machine is a tool designed to cut or shape metal with high precision. These machines can range from simple handheld cutters to complex, computer-controlled systems used in large-scale manufacturing.

In Singapore, these machines are used across industries like:

- Precision engineering

- Aerospace and marine

- Construction and fabrication

- Medical device manufacturing

Types of Metal Cutting Machines

There are several types of metal cutting machines, each designed for specific materials, thicknesses, and production requirements:

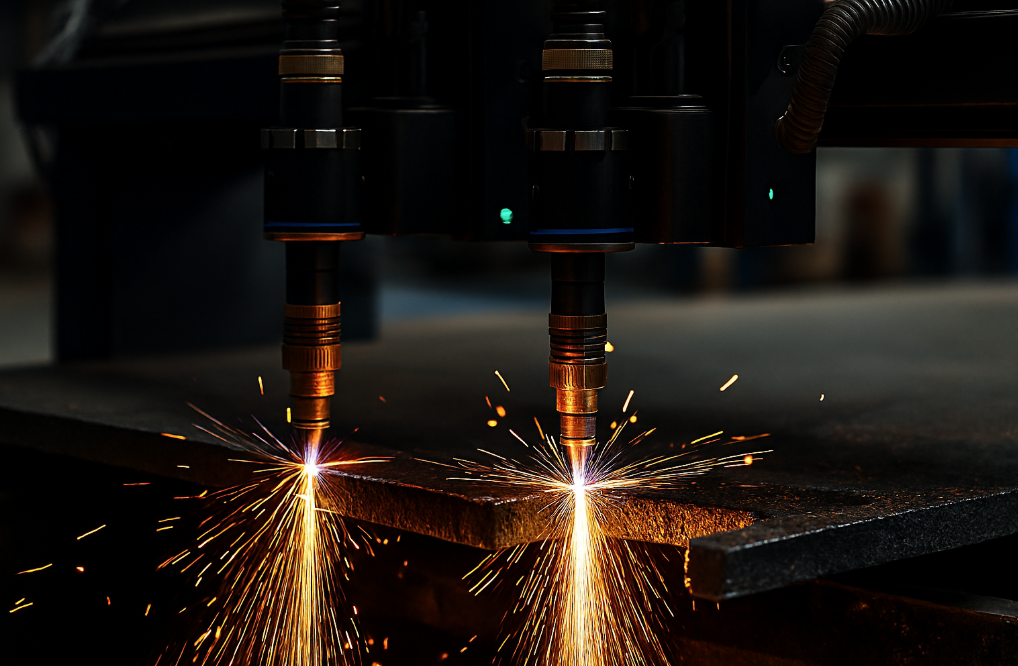

- Laser Cutting Machines: Ideal for high-precision and complex shapes. Commonly used to cut stainless steel, mild steel, and aluminum with clean, burr-free edges.

- Plasma Cutters: Suitable for medium to thick metals. Offers fast cutting speeds and is cost-effective for structural and industrial applications.

- Waterjet Cutting Machines: Best for heat-sensitive materials and thick metals. Uses high-pressure water with abrasive particles to deliver precise cuts without thermal distortion.

- Mechanical Saws (Band Saw, Cold Saw): Excellent for straight cuts on bars, tubes, and profiles. Often used in construction and metal fabrication workshops.

- Oxy-Fuel Cutting Machines: Used for cutting thick steel plates (up to 300mm). Operates with a mix of oxygen and fuel gas, commonly found in heavy industrial settings.

- Handheld Metal Cutters (Grinders, Shears, Snips): Portable and convenient for on-site work or small jobs. Ideal for cutting sheet metal or making quick adjustments.

- CNC Metal Cutting Machines: Computer-controlled systems that offer automation, repeatability, and tight tolerances. Used in high-volume and precision manufacturing environments.

Each machine serves a unique purpose from small hand tools for quick tasks to heavy industrial cutters for mass production. The choice depends on the project’s size, material type, desired precision, and budget.

When designing parts for laser cutting or CNC milling, edge geometry matters. Choosing between a chamfer or fillet can affect both aesthetics and structural integrity.

Top 10 Best Metal Cutting Machines

1. Industrial Fiber Laser Cutter

Best for high-precision sheet metal cutting (steel, aluminum, stainless steel). This type of machine uses concentrated laser beams to deliver extremely precise cuts with minimal material waste. Ideal for clean, burr-free edges and tight tolerances. Frequently used in high-volume manufacturing environments.

Laser cutting offers clean edges and minimal post-processing, especially for thin metals. However, in projects requiring more dimensional shaping, it’s important to compare laser cutting and CNC milling processes based on material type and tolerances.

2. CNC Plasma Cutting Machine

Best for cutting thick steel and other conductive metals. This machine uses a high-temperature plasma arc to melt and blow away metal. It’s a cost-effective option for cutting heavy plates, frames, and structural steel, especially in fabrication and construction industries.

3. Waterjet Cutting Machine

Best for heat-sensitive materials or complex shapes. Using high-pressure water mixed with abrasives, this machine cuts metal without heat, making it perfect for materials that can warp or deform under high temperatures. Common in aerospace, medical, and electronics industries.

4. CNC Guillotine Shear

Best for straight-line cuts on sheet metal. This hydraulic or mechanical system slices sheets with a downward cutting blade. It’s fast, clean, and ideal for preparing flat stock or cutting multiple pieces to length in one pass. Great for metal service centers and fabrication shops.

5. Industrial Abrasive Cut-Off Saw

Best for cutting rods, pipes, and solid bars. This machine uses an abrasive disc to grind through metal. While not ideal for fine tolerances, it’s a rugged, reliable solution for bulk cutting of hard materials, rebar, or tubing.

6. CNC Laser Engraving & Cutting Table

Best for light-duty metal engraving and thin sheet cutting. Commonly used in sign-making, prototyping, and custom part production, this machine provides precise engraving and cutting in a single pass. Suitable for workshops that need flexibility with intricate metal designs.

7. Small Bench-Top Metal Shear

Best for thin sheet metal and light gauge aluminum. Perfect for smaller shops, this compact machine manually or hydraulically shears lightweight metals. It’s ideal for hobbyists, product developers, or custom fabricators working with sheet material under 3mm thick.

8. Portable Plasma Cutter

Best for on-site cutting jobs or field work. This handheld machine cuts metal with a compressed air plasma arc. It’s lightweight, mobile, and excellent for maintenance teams, field fabricators, or small repair jobs where larger machines aren’t practical.

9. Horizontal Band Saw

Best for straight and angled cuts on solid or hollow stock. This saw uses a toothed blade to cut steel bars, tubes, and structural profiles. Great for repetitive cuts and known for its accuracy and quiet operation. Frequently found in metalworking and machine shops.

10. Handheld Metal Cutting Tool (Grinder or Nibbler)

Best for quick cuts, trimming, or repairs. Hand tools like angle grinders, nibblers, or electric shears are essential for small projects or when flexibility is needed. They’re not suitable for production, but they play a critical role in prototyping or fitting work.

For more complex cuts involving grooves, slots, or surface finishing, a milling machine can complement cutting operations by removing material precisely from specific sections of a workpiece.

How to Choose Metal Cutting Machine for Your Needs

When evaluating your options, consider the following factors:

- Material type and thickness – Some machines excel with thin aluminum, others with thick steel.

- Cutting precision required – If you need tolerances below ±0.1 mm, laser or waterjet is preferred.

- Volume of work – For high output, go for CNC or automated systems; for small jobs, a bench or hand tool may suffice.

- Available space – Industrial machines can take up several square meters, so plan accordingly.

- Budget – Entry-level machines are affordable, while industrial systems may require significant investment.

- Maintenance and support – Ensure parts and servicing are accessible in Singapore to minimize downtime.

If you’re working with aluminum or stainless steel, choosing the right cutting process can impact both precision and cost. Understanding how sheet metal laser cutting pricing is calculated can help you make informed decisions during production planning.

In certain applications, especially those needing airflow or structural reinforcement, expanded metal provides a lightweight yet durable alternative to solid sheet metal.

Small vs Industrial Metal Cutting Machines

Small metal cutting machines are portable, cost-effective tools ideal for light-duty work, prototyping, or on-site repairs. They’re best for cutting thin materials like aluminum or sheet steel with manual or semi-automatic control.

Industrial metal cutting machines, on the other hand, are large, high-powered systems built for continuous operation, precision, and volume. These machines use CNC automation to cut thick metals (steel, stainless steel, etc.) at scale, making them ideal for factories and manufacturing plants.

A SME used a portable plasma cutter for onsite adjustments. Later, to meet bulk orders, they partnered with The Monster Builder to use our industrial fiber laser systems, ensuring faster turnaround and higher cut quality.

Singapore’s Trusted Partner for Precision Metal Cutting

At The Monster Builder, we offer comprehensive metal cutting solutions tailored to meet the diverse needs of businesses in Singapore from startups and prototyping teams to full-scale manufacturing operations.

Our facility is equipped to handle a wide range of materials, including aluminum, stainless steel, and mild steel, using advanced technologies such as CNC laser cutting, plasma cutting, and mechanical shearing. What sets us apart is our commitment to fast turnaround times with no minimum order quantity, making us an ideal partner for both urgent jobs and ongoing production.

As a locally operated company, we provide direct support within Singapore, ensuring responsive service and minimized downtime. Every cut we deliver meets strict quality standards, with precision tolerances as tight as ±0.1 mm. Whether you’re building your first product or scaling up for mass production, The Monster Builder has the tools, expertise, and reliability to support your metal cutting needs from start to finish. Contact us today!